Rotating electrophoresis tooling

A technology of electrophoresis and tooling, applied in the direction of electrophoresis plating, electrolytic paint, coating, etc., can solve the problems of low electrophoresis effect and long time spent, and achieve good electrophoresis effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with accompanying drawing, protection scope of the present invention is not limited to the following:

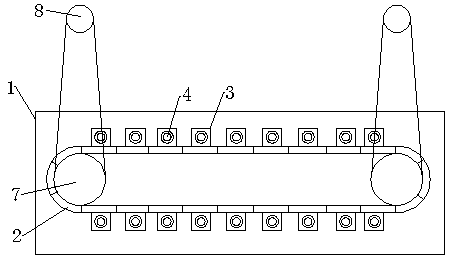

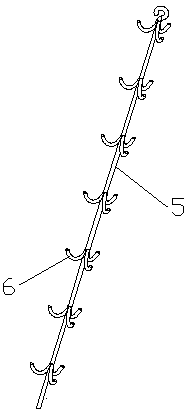

[0018] Such as figure 1 with figure 2 As shown, a rotating electrophoresis tooling includes an electrophoresis frame 1, and the front and rear positions of the electrophoresis frame 1 are respectively provided with a rotating track 2, the rotating track 2 at the front and rear positions, and each track joint on the rotating track 2 A mounting block 3 is fixed, and a horizontal bar 4 is installed through bearings between the front and rear relative mounting blocks 3, and a vertical bar 5 is hung on the horizontal bar 4, and a plurality of hooks 6 are evenly arranged on the vertical bar 5;

[0019] The left and right ends of the rotating crawler belt 2 are both sleeved on the rotating shaft 7, and the rotating shaft 7 is installed on the electrophoresis frame 1 through a support, and the rotating sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com