Electrophoresis auxiliary device for automobile parts production

A technology for auto parts and auxiliary devices, applied in the direction of electrophoretic plating, electrolytic paint, coating, etc., can solve the problems of slow surface electrophoretic coloring speed, etc., and achieve high electrophoretic speed, good electrophoretic effect, and fast drying Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

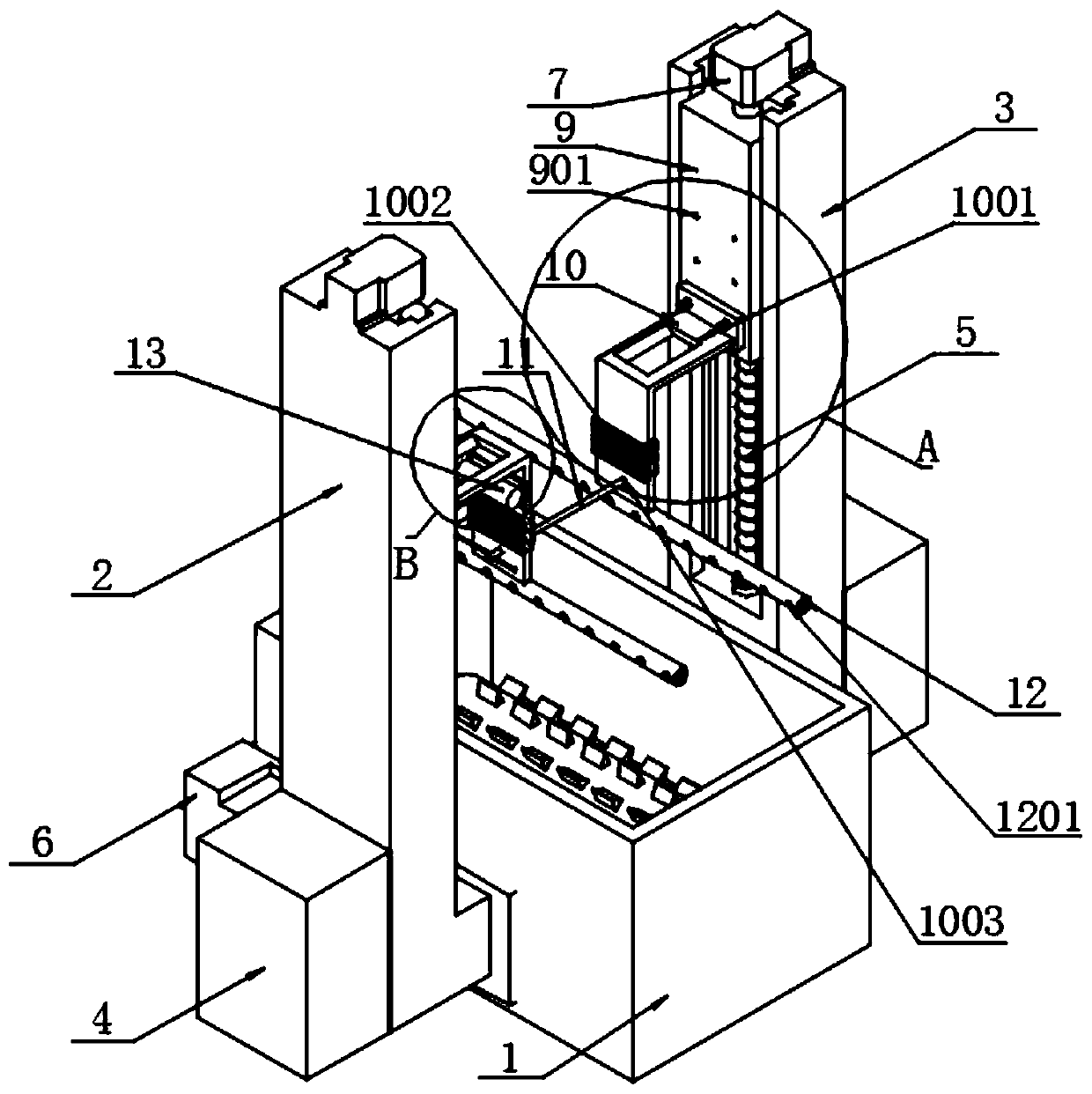

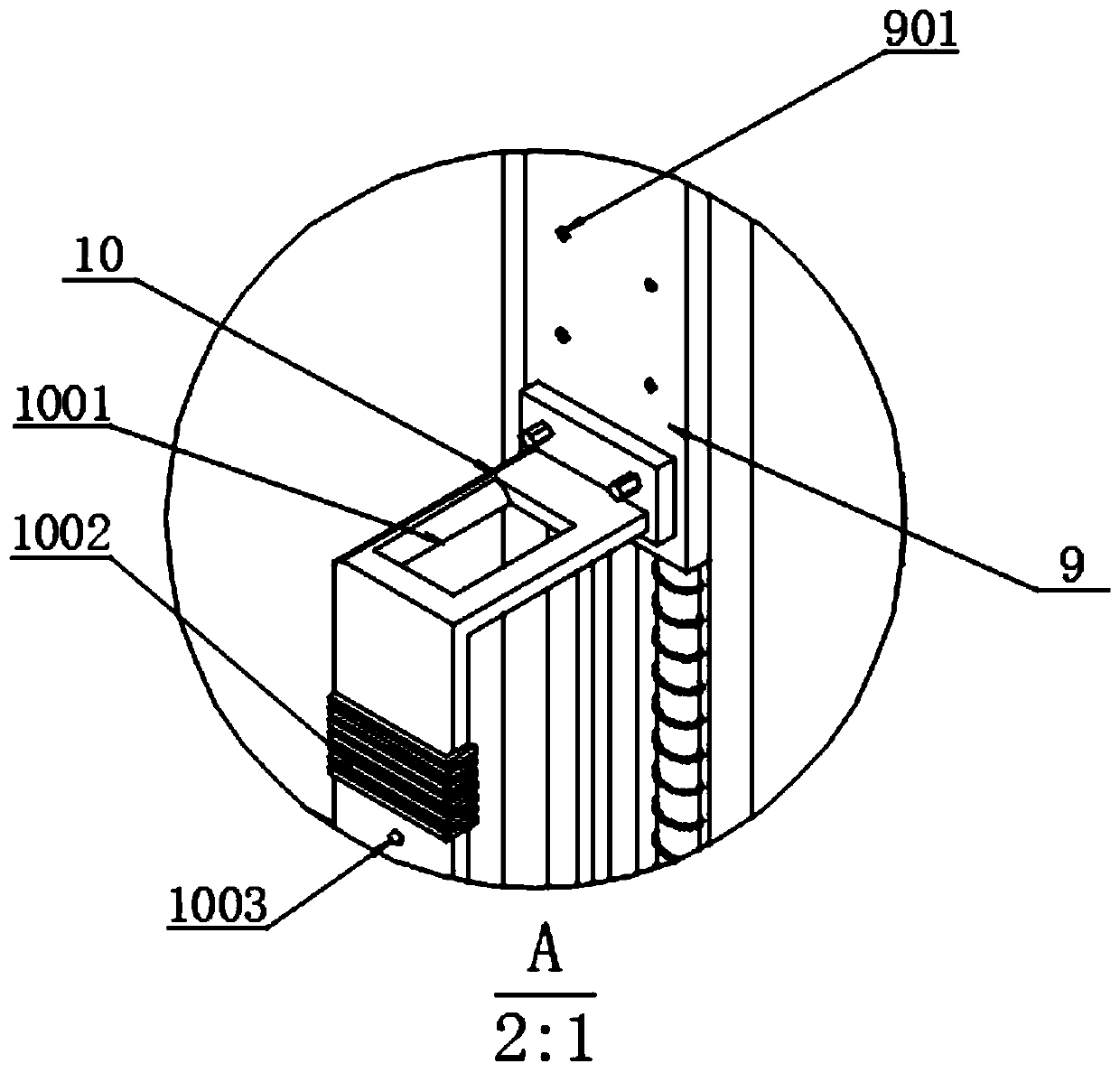

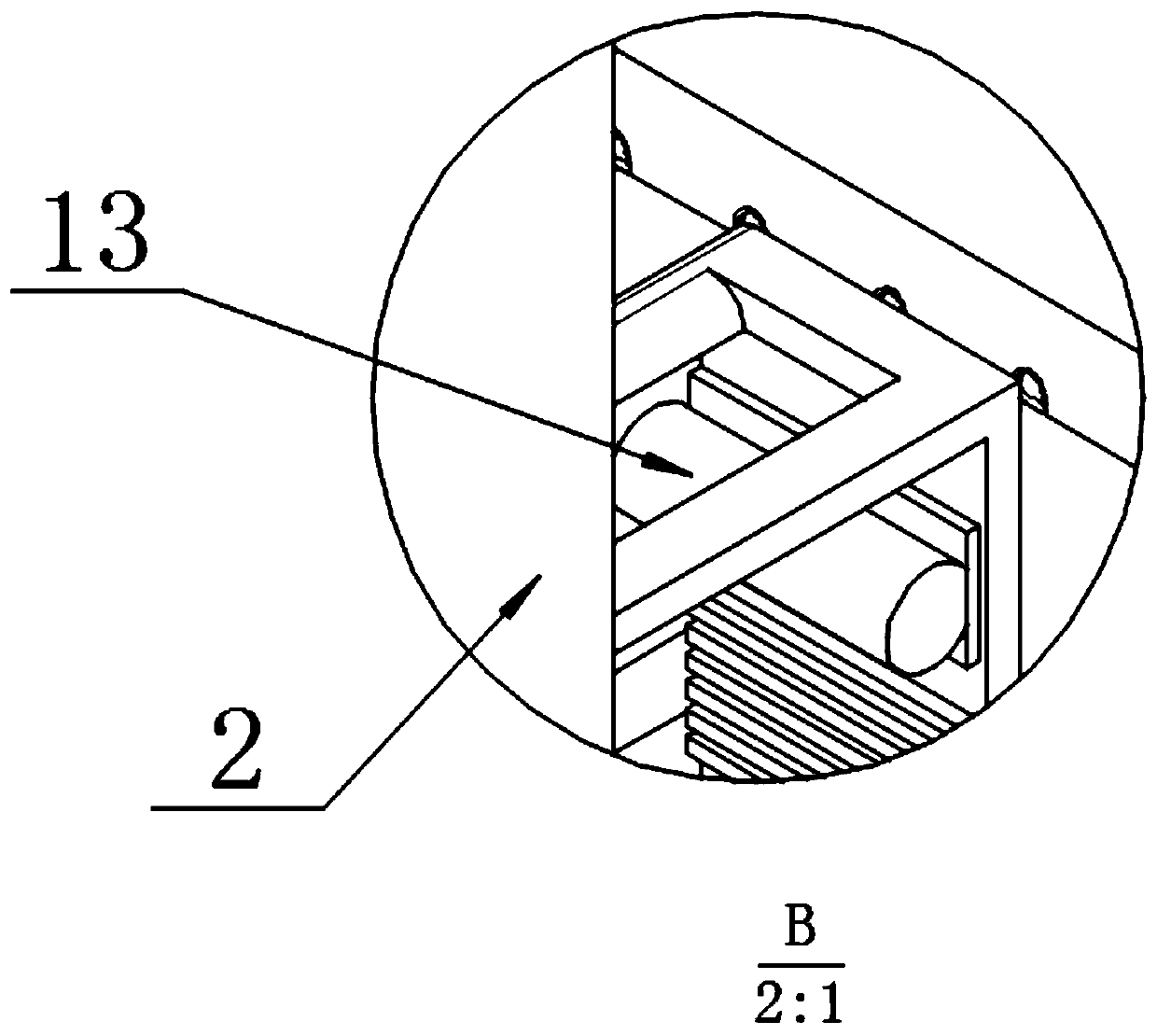

[0030] as attached figure 1 To attach Figure 8 Shown:

[0031] The invention provides an electrophoresis auxiliary device for the production of auto parts, including: an electrophoresis tank main body 1, a left station stand 2, a right station stand 3, a first motor box 4, a lead screw 5, and a second motor box 6 , bearing seat 7, operation panel 8, moving seat 9, adjustment hole 901, sinking frame 10, grip groove 1001, rubber corrugated section 1002, connecting hole 1003, accessory rod 11, hanging rod 12, workpiece hanging hole 1201, small vibration Motor 13, pulley protective cover 14, function rod 15 and blocking plate 1501; The frame structure is exactly the same; the left station stand 2 and the right station stand 3 are all chute structures, and a moving seat 9 is slidably fitted in their chute, and the moving seat 9 is all passed through the work station. The leading screw 5 installed in the position stand chute realizes sliding up and down, and the top surface and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com