A high-efficiency skimming and mud scraping device

A high-efficiency scraper technology, which is applied to the feeding/discharging device, separation method, and sedimentation separation of the settling tank, can solve the problems of high false trigger probability, inability to turn over the scraper, and poor connection reliability, etc., and achieve reduction The degree of agitation, not easy to trigger by mistake, and the effect of high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

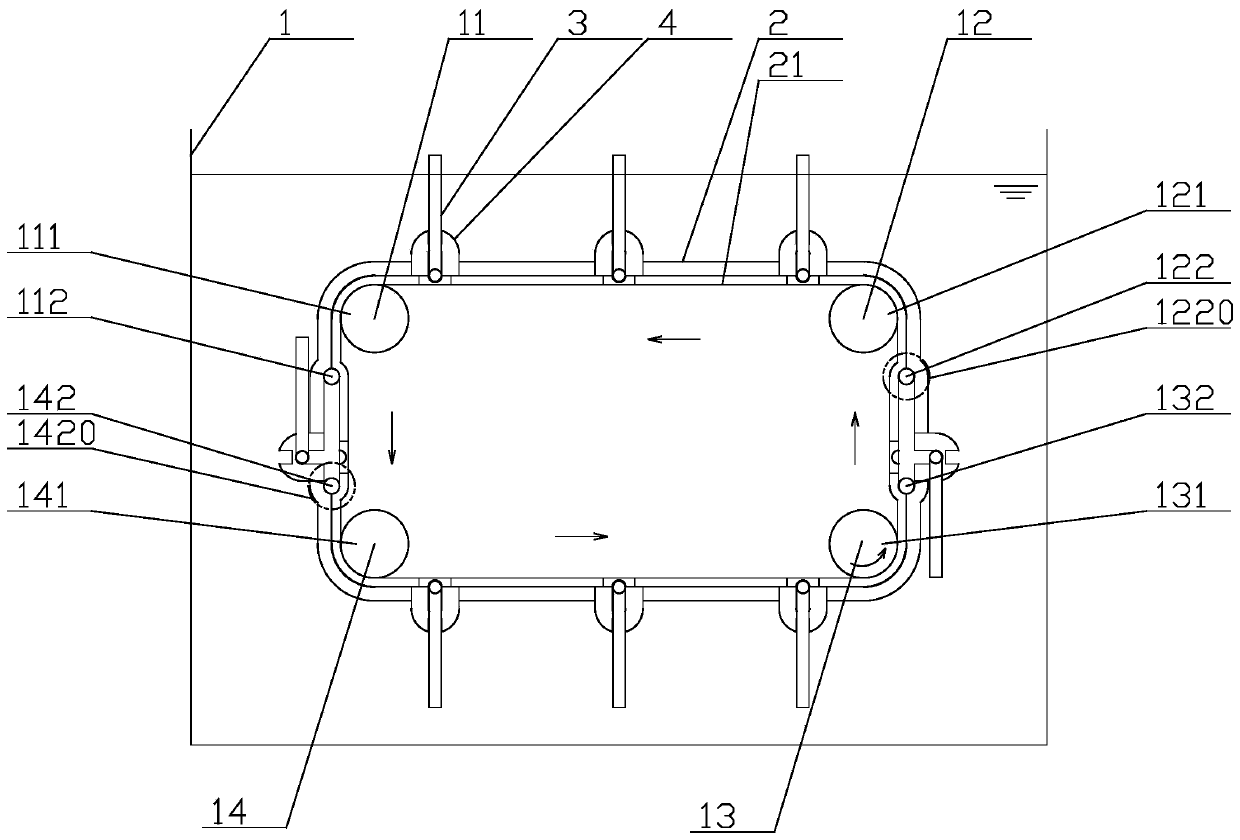

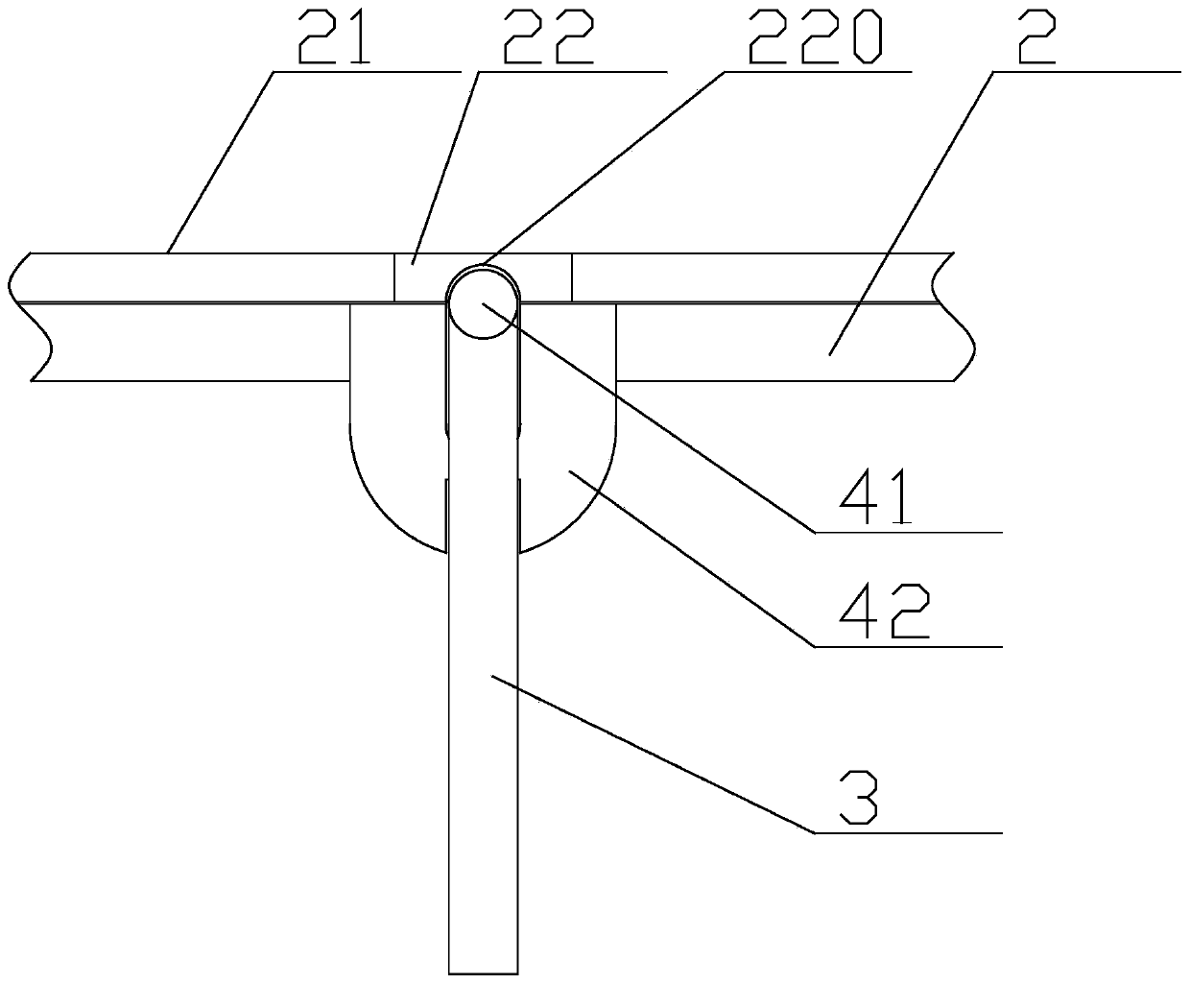

[0030] The invention as Figure 1-9 As shown, it is set in the sedimentation tank 1, including a pulley 11, a pulley 2 12, a pulley 3 13, a pulley 4 14, a conveyor belt 2, a number of scrapers 3 and a number of connecting components 4, the pulley 1 11 and pulley two 12 are arranged at the two ends of the position below the liquid level in the sedimentation tank 1, and the pulley three 13 and the pulley four 14 are arranged at the two ends of the upper position of the bottom surface of the sedimentation tank 1, and the conveyor belt 2 is looped sequentially It is wound on the first pulley 11, the second pulley 12, the third pulley 13, and the fourth pulley 14; the surfaces of the first pulley, the second pulley, the third pulley, and the fourth pulley are all provided with some anti-skid protrusions. rise;

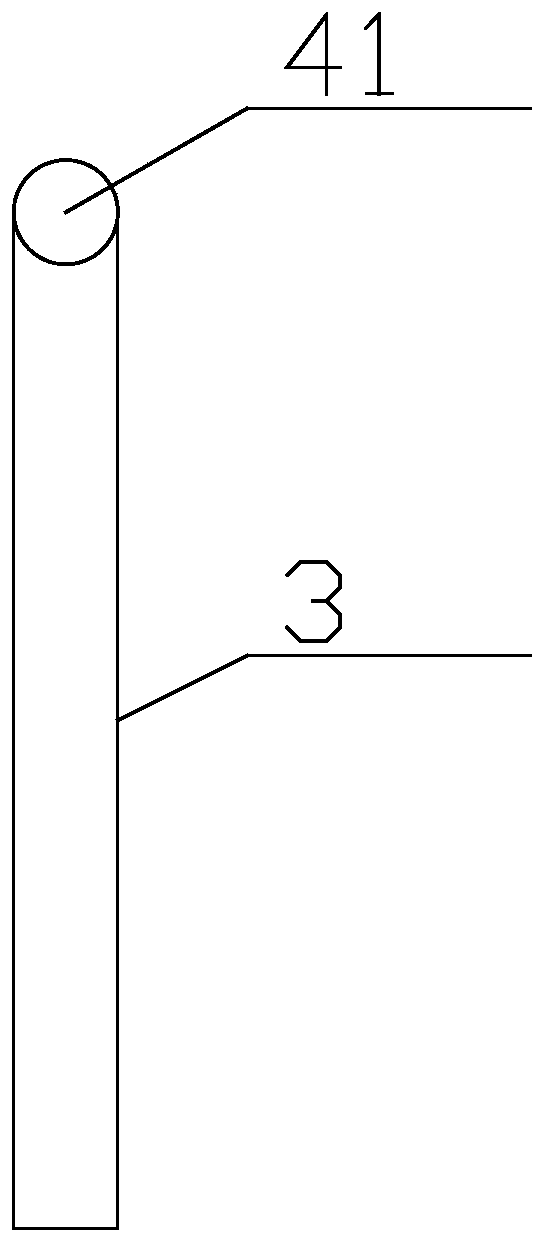

[0031] Several scrapers 3 are connected to the conveyor belt 2 through a connecting assembly 4;

[0032] The inner side of the conveyor belt 2 is also provided with a sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com