Rolling, shaping and smoothing mechanism for stainless steel roll steel finished products

A technology for steel products and stainless steel, which is applied to the field of coiling, shaping and leveling mechanisms for stainless steel coil steel products. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The technical solutions of the present invention will be further specifically described below through the embodiments and in conjunction with the accompanying drawings.

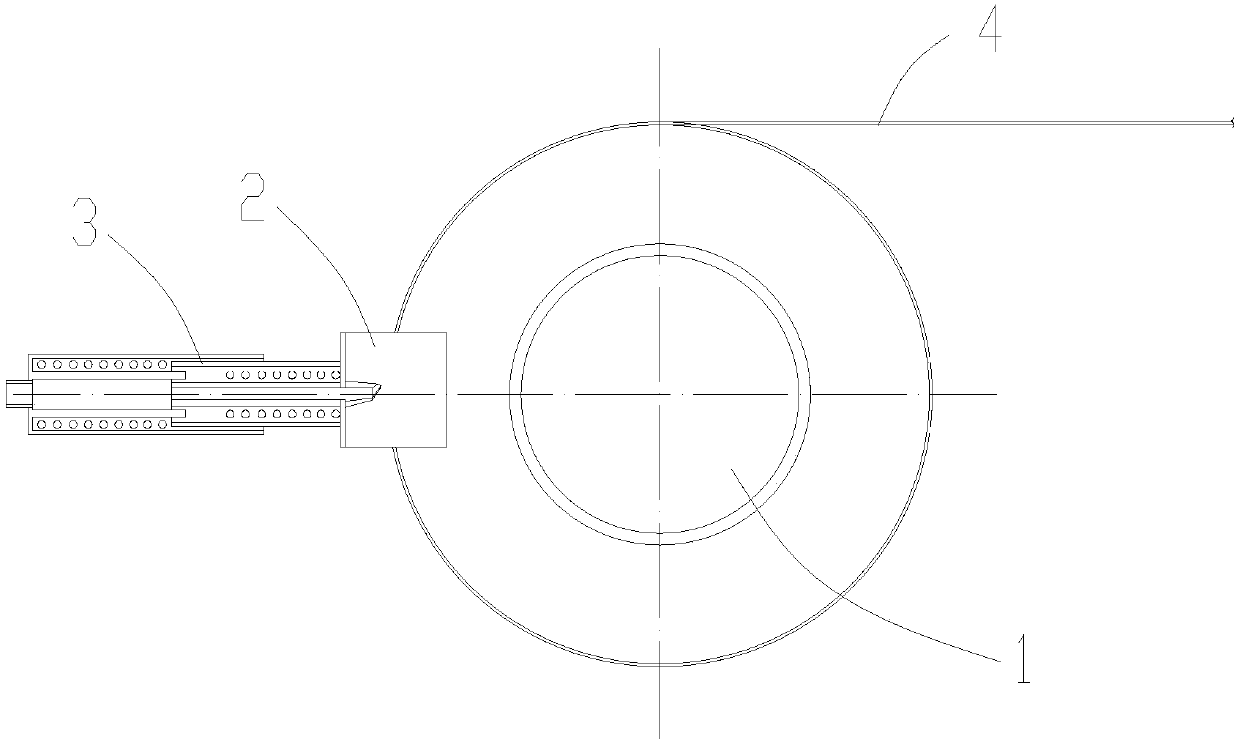

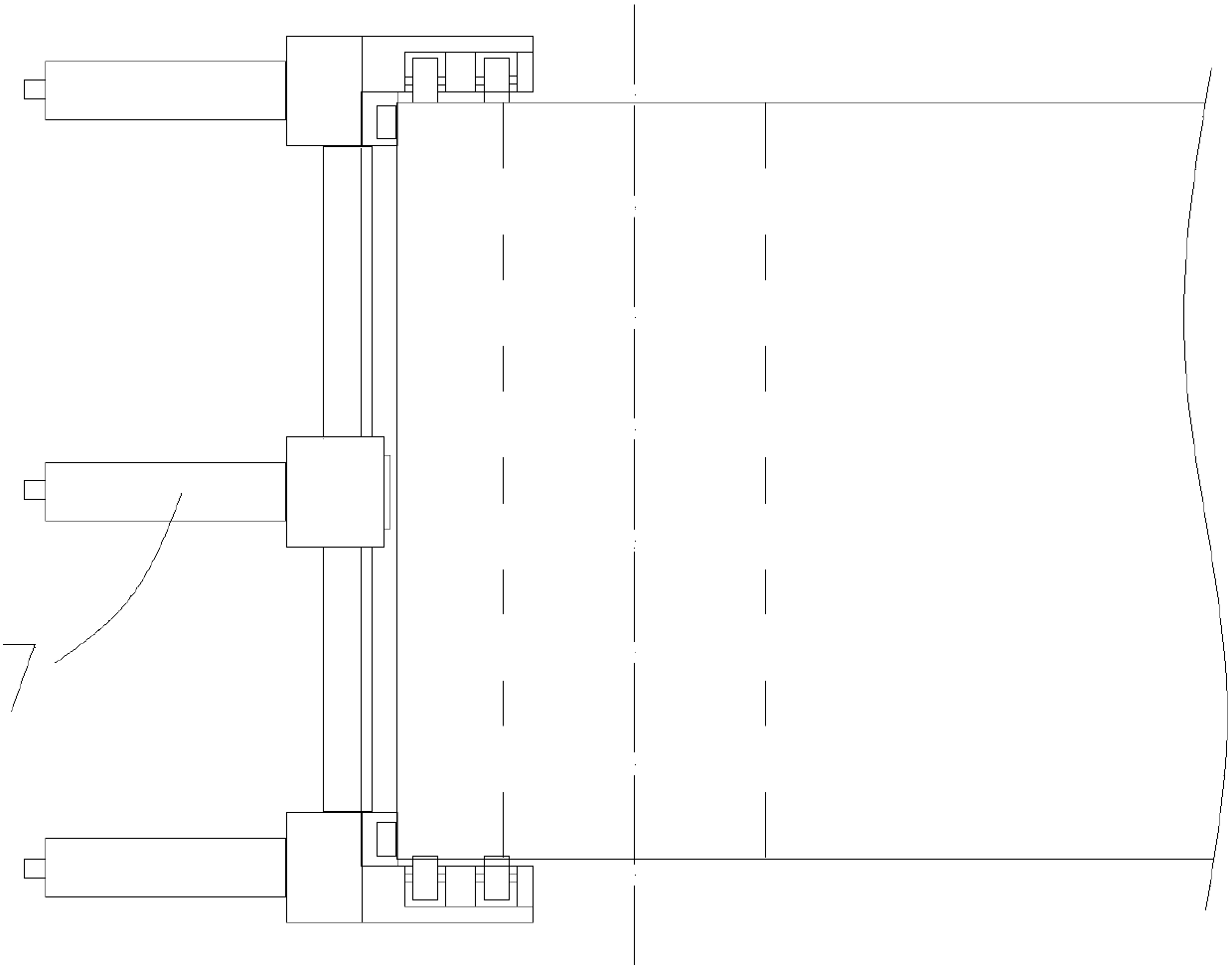

[0021] In this embodiment, a kind of coil shaping device for stainless steel coiled steel products, such as figure 1 , figure 2 As shown, it includes the main cylinder body 1 of the coiler, and three smoothing incremental pushing mechanisms 3 arranged perpendicular to the central axis of the main cylinder body 1 are arranged on the working surface of the main cylinder body 1. The three incremental pushing mechanisms 3 are respectively Arranged at both ends of the length direction of the main cylinder 1 and in the middle of the length of the main cylinder 1 .

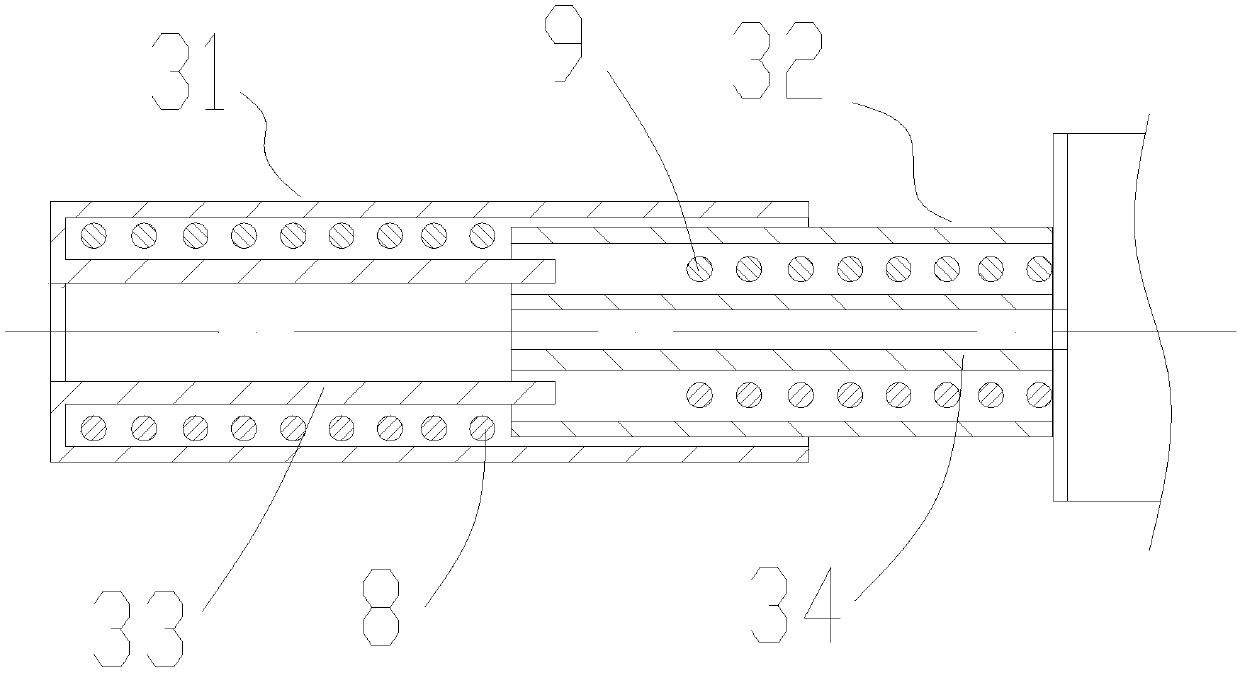

[0022] The incremental pushing mechanism 3 includes a primary sleeve 32 and a secondary sleeve 31 connected in series with the primary sleeve 32; the primary sleeve 32 is provided with a primary force spring 8, and the secondary sleeve 31 is pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com