High-precision drilling platform for construction

A drilling platform and high-precision technology, applied in drilling equipment and methods, earth-moving drilling, drilling equipment, etc., can solve problems such as holes that cannot reach the expected depth and cannot accurately control the depth of the drill bit. , to achieve the effect of stable speed and reduced work intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

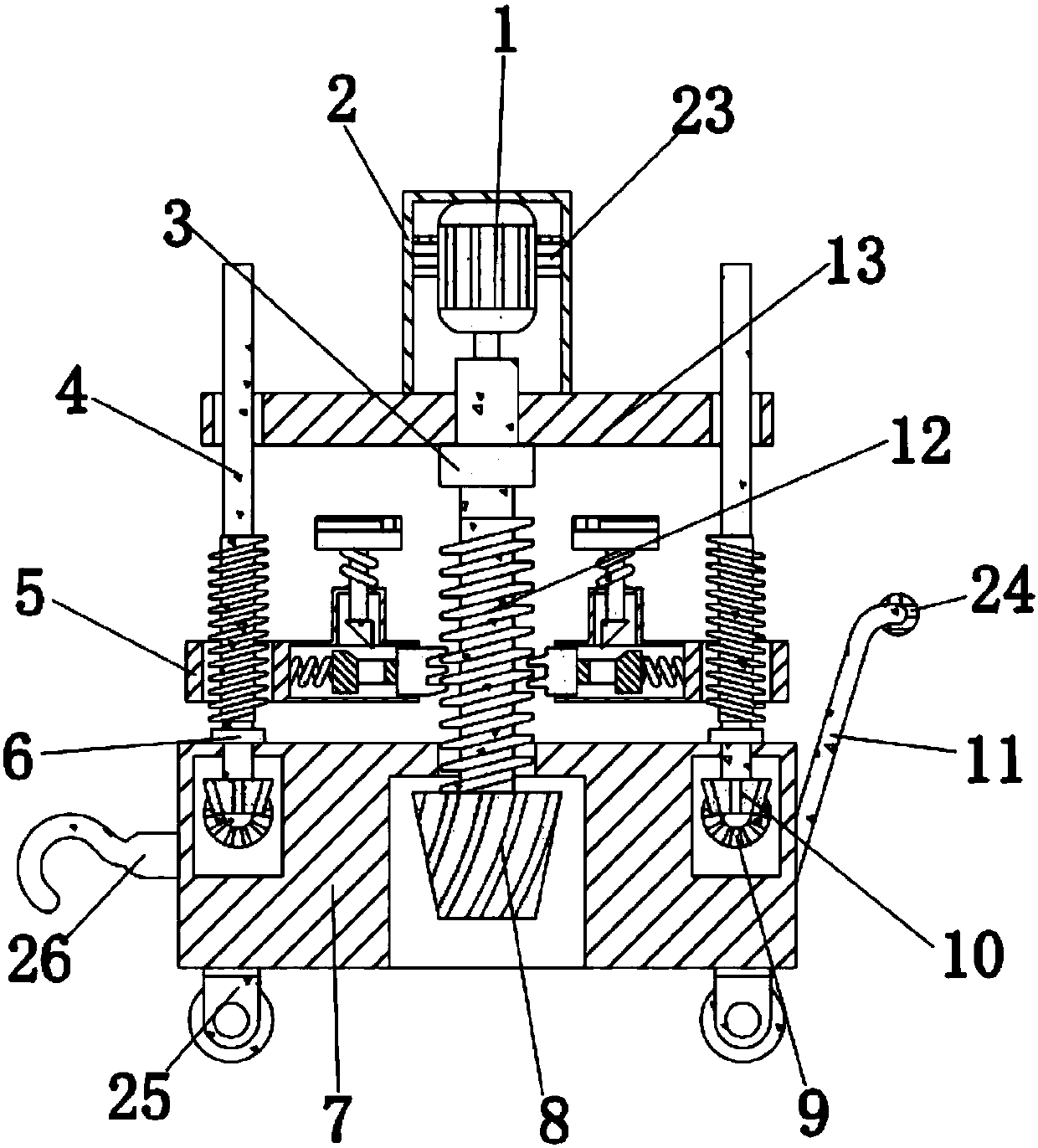

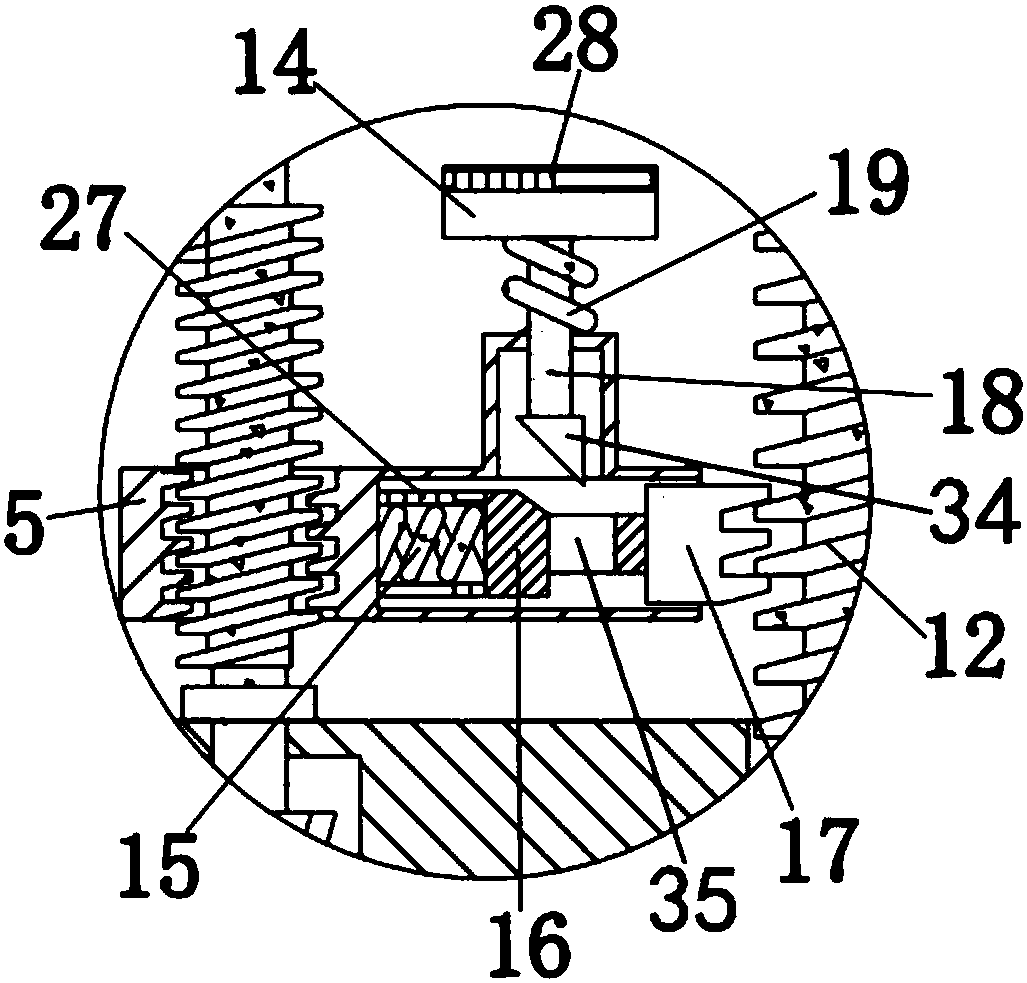

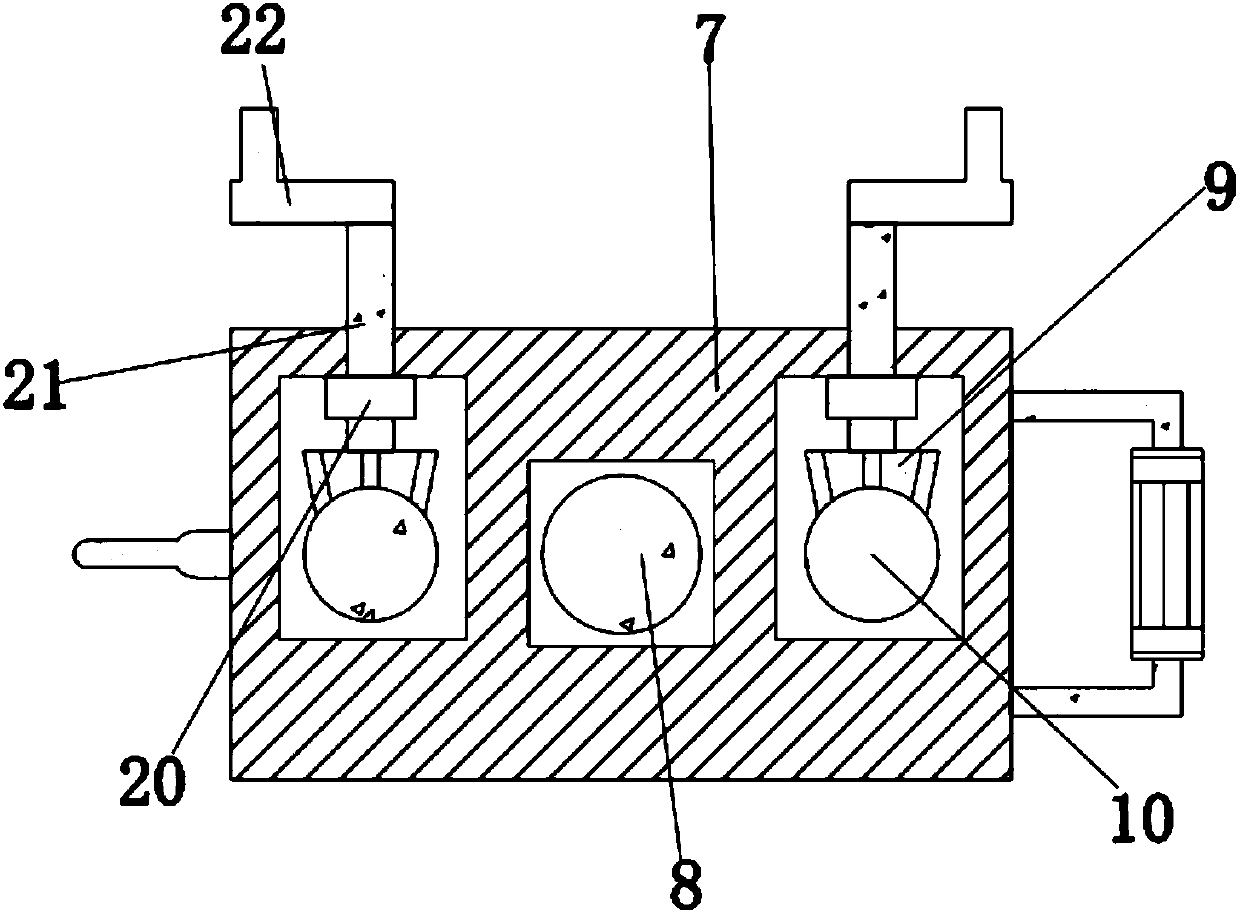

[0030] Such as Figure 1~4 As shown, a drilling platform for high-precision bridge construction includes a base 7, a drill bit 8, and a motor 1. One end of the drill bit 8 is fixed to a second lead screw 12, and the second lead screw 12 carries the drill bit 8 through the base 7 to reciprocate up and down. ; The upper part of the second lead screw 12 is rotatably connected with a second baffle 13 , and the second lead screw 12 passes through the second baffle 13 and is connected to the motor 1 . The outer side of the second lead screw 12 is meshed with a stabilizing device, the stabilizing device fixes the second lead screw 12, and the second lead screw 12 reciprocates up and down through the stabilizing device. The stabilizing device comprises a first baffle plate 5, a tooth plate 17, and a first lead screw 4. The tooth plate 17 is sleeved on the inner side of the first baffle plate 5, and the first baffle plate 5 connects with the second lead screw 12 through the tooth plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com