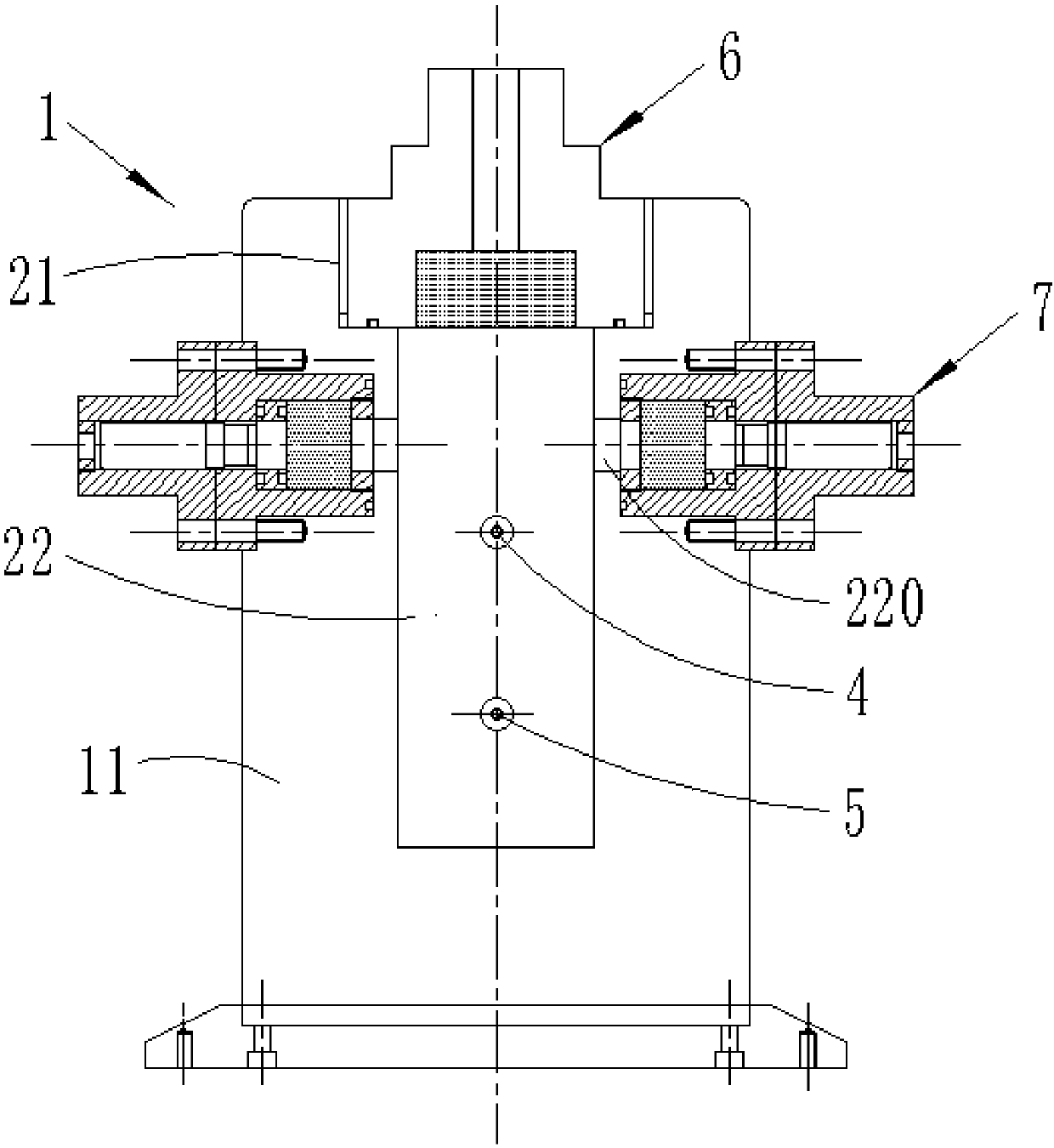

High-pressure test cylinder, test machine and test method

A technology of high-pressure testing and cylinder block, which is applied in the field of clocks and watches, can solve the problems of inability to detect the use of high-depth diving watches, and achieve the effect of simple and fast operation and good sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0059] Furthermore, please also refer to Figure 6 and Figure 7, as a specific embodiment of the bracket 3 provided by the present invention, the high-pressure test cylinder 1 also includes a bracket 3 supporting the test workpiece, the bracket 3 is placed in the inner cavity 22, and the bracket 3 includes at least one layer of trays 32 and The bracket 33 supporting the tray 32 is provided with a drainage hole 320 , and the bracket 33 is connected with a handle 31 . Specifically, the bracket 3 is in the shape of "I", and the bracket 3 includes two pallets 32 in a cylindrical configuration, and a bracket 33 in a cylindrical configuration for connecting the two pallets 32 is arranged between the two pallets 32, and the two pallets 32 A plurality of uniformly arranged first drainage holes 320 are symmetrically arranged on the block tray 32 , and the above-mentioned handle 31 is grooved and fixedly connected to any one of the trays 32 . With this structure, before the test, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com