Cable stripping tool with blade depth adjusting function

A stripping tool and cable technology, applied in the field of electric power, can solve the problems of inability to precisely adjust the stripping depth, slippage, and poor targeting of the stripping knife, so as to save the depth adjustment process, improve work efficiency, and facilitate the operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

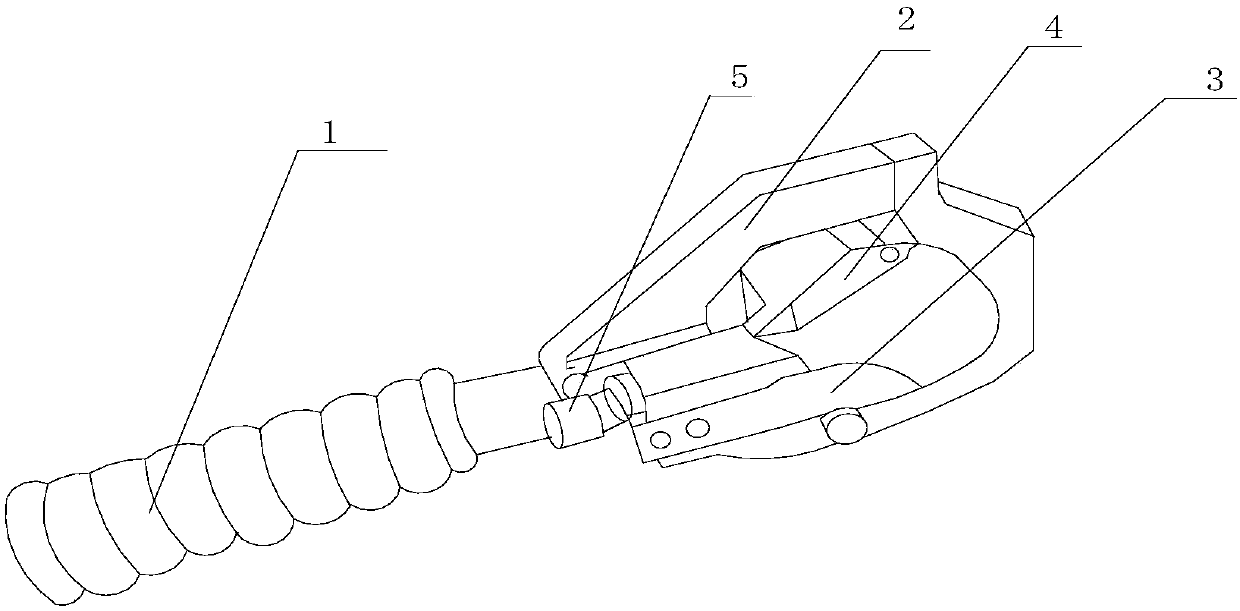

[0017] Such as figure 1 As shown, the present invention includes a cable stripping tool capable of adjusting the depth of the blade, including a handle 1, a cable stripping head 2, a shear blade 3 and a depth adjustment knob 5, and the handle 1 is fixedly connected to the cable stripping head 2, and the The depth adjustment knob 5 is fixed on the connecting end of the handle 1 and the cable stripping head 2, the shear blade 2 is installed on the outer wall of the depth adjustment knob 5 in parallel, and is connected with the depth adjustment knob 5, and the edge of the shear blade 3 faces the cable stripper. The wire release hole on the thread head 2,

[0018] The shearing blade 3 can move back and forth under the drive of the depth adjustment knob 5, and a limit plate 4 is also installed on the inner wall of the wire-proof hole of the cable stripping head 2. The limit plate 4 and the shearing blade 3 are symmetrically distributed, and the cable stripping head 2 The size of t...

Embodiment 2

[0021] This embodiment is preferably as follows on the basis of Embodiment 1: the depth adjustment knob 5 is provided with a plurality of fixed depth gears. The setting of the fixed gear is convenient for the operator to operate, saves the long-term depth adjustment process, saves time and effort, and improves work efficiency.

[0022] Limiting plate 4 one ends are suspended in the air, and the other end can rotate around the connection end with cable stripping head 2. The limit plate adopts a rotatable structure, which can better limit the position of the power cable and further avoid slippage.

[0023] The frame of the cable stripping head 2 is formed by connecting two steel plates with bolts. When a problem occurs locally on the power cable or the cable stripping head, the bolt can be opened for partial repair, and the maintenance cost is low.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com