Cooling device and frequency converter having the same

A heat sink and frequency converter technology, which is applied in the modification of power electronics, cooling/ventilation/heating transformation, electrical components, etc., can solve problems such as short circuit of electrical components, threat to normal operation of frequency converters, affecting work safety and service life, etc. achieve the effect of avoiding harm

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in detail below with reference to the accompanying drawings and examples.

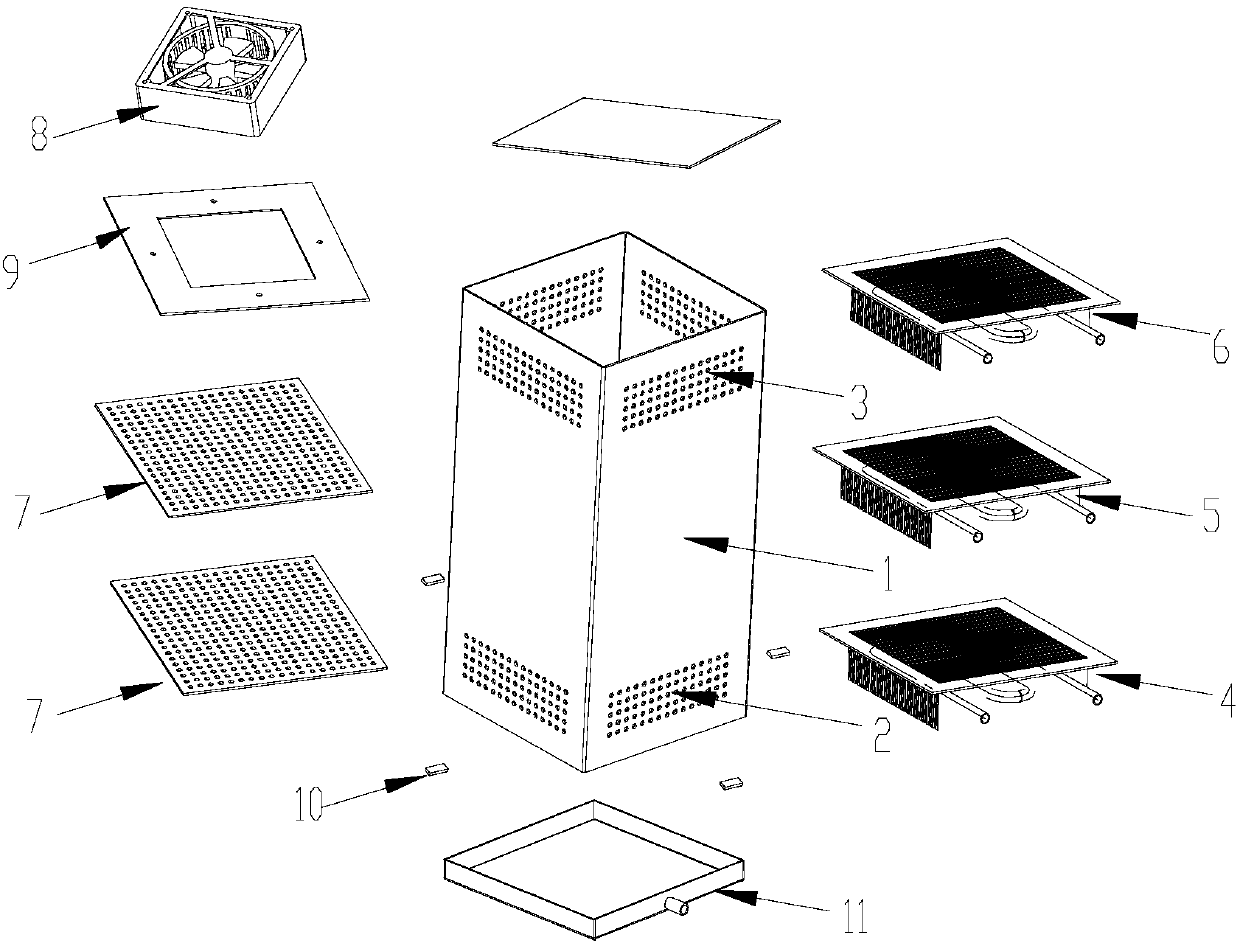

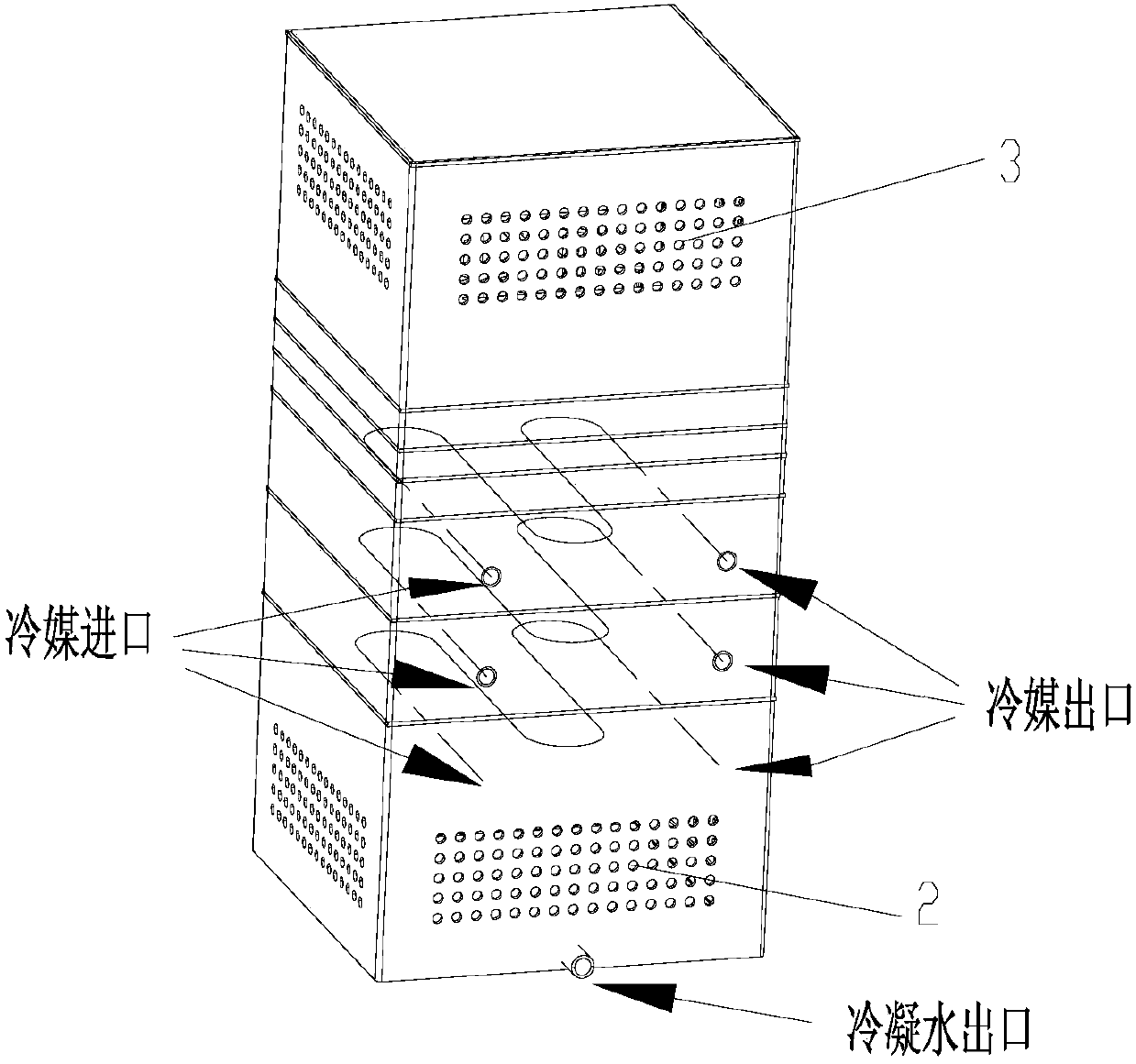

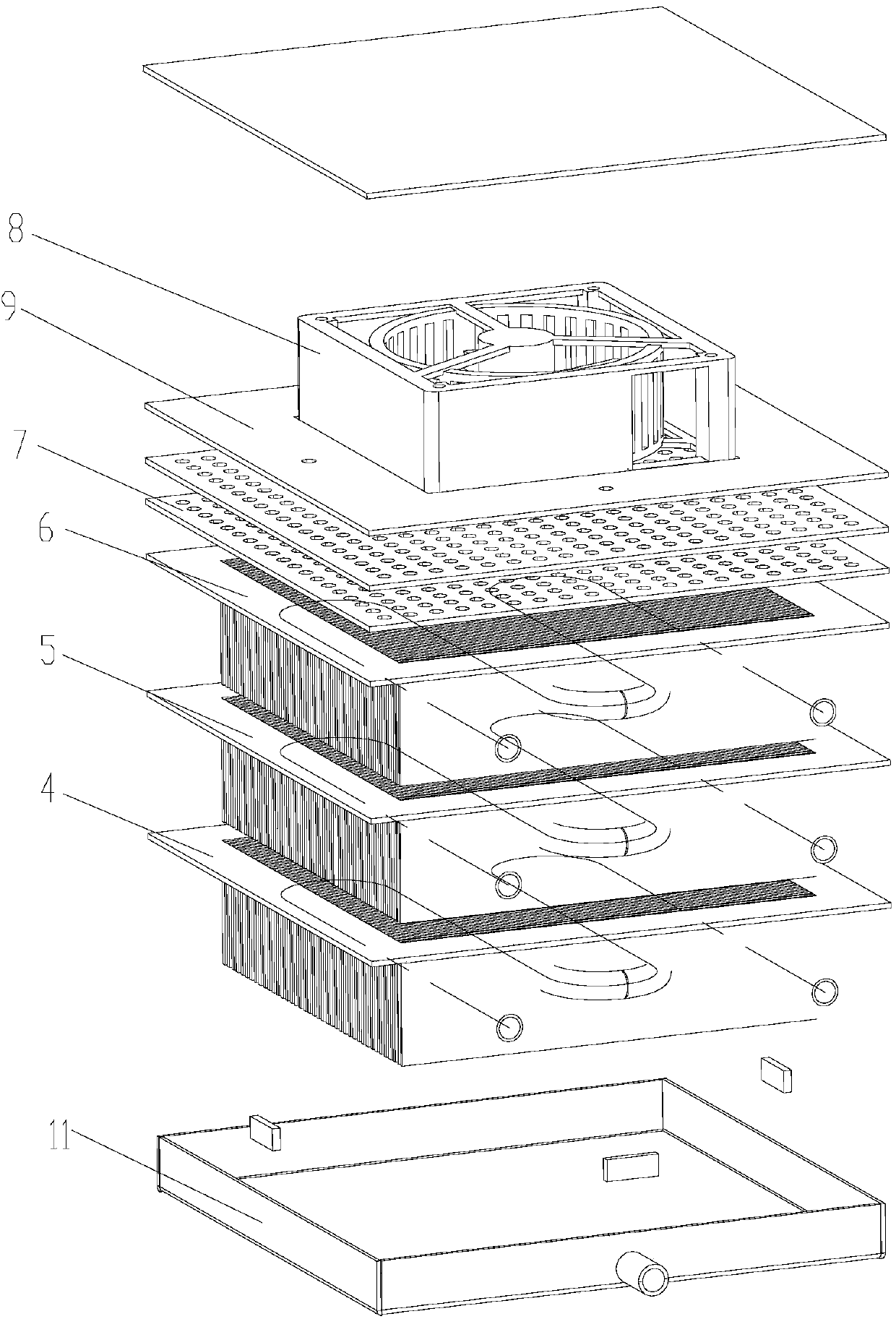

[0028] like Figure 1-3 As shown, according to an embodiment of the present invention, the radiator includes a radiator housing 1, the radiator housing 1 has an inner cavity, an air inlet 2 and an air outlet 3 communicating with the inner cavity, and the radiator also includes a The inner dehumidification assembly includes a first cooling and dehumidification unit 4 .

[0029] By setting the first cooling and dehumidifying part 4 in the radiator shell, the radiator shell cooperates with the first cooling and dehumidifying part 4 to cool down the air flow, make the water vapor in it condense, and form liquid droplets to separate from the air flow. Dehumidification of airflow. Since the air flow is dehumidified in the radiator shell, the condensed liquid droplets can be left in the radiator shell, avoiding the harm caused by the condensation water formed b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com