Main housing side hole punching device for air conditioner compressor

A technology of air-conditioning compressors and stamping devices, applied in the direction of feeding devices, positioning devices, storage devices, etc., can solve the problems affecting the working efficiency of the main shell opening, reduce manual participation, improve work efficiency, and improve processing The effect of precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The specific embodiments of the present invention will be further described in detail below in conjunction with the drawings and embodiments of the specification:

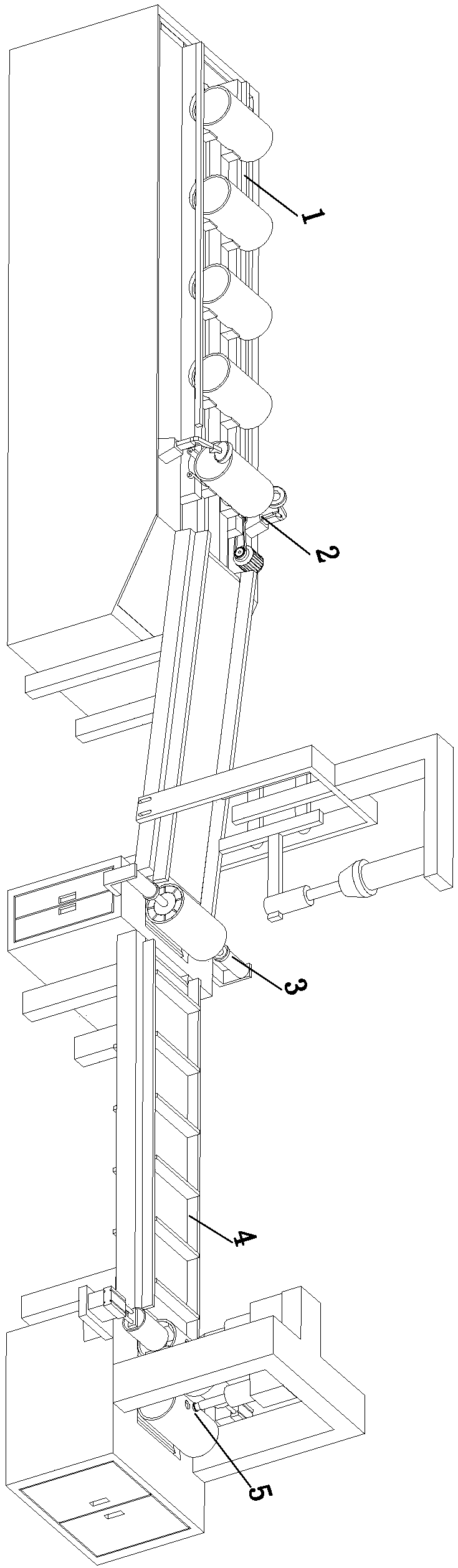

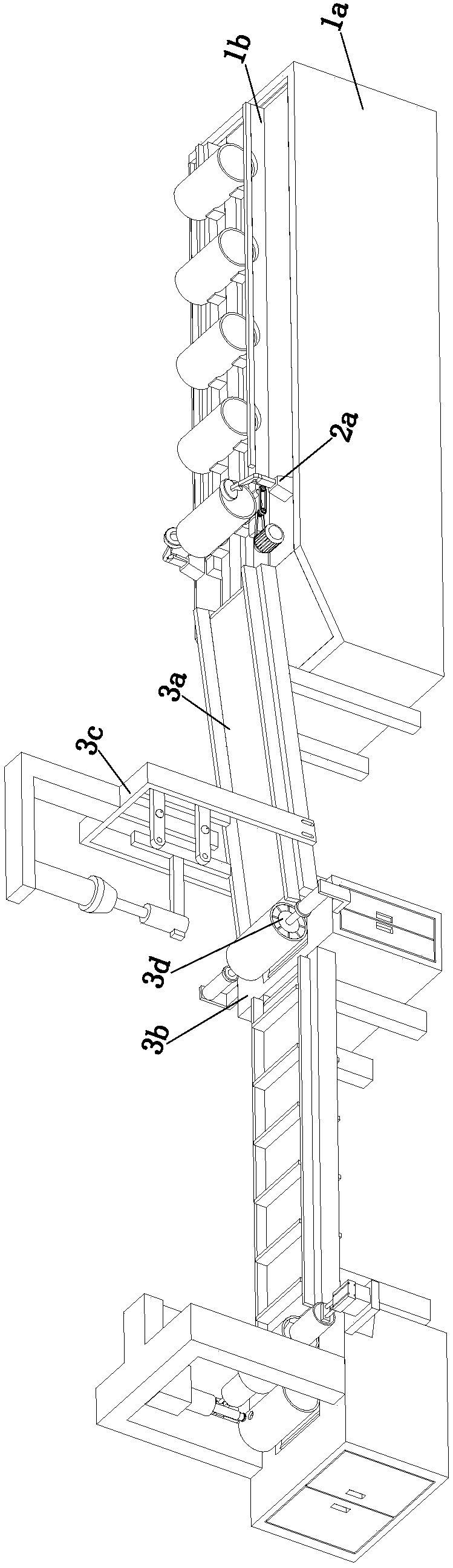

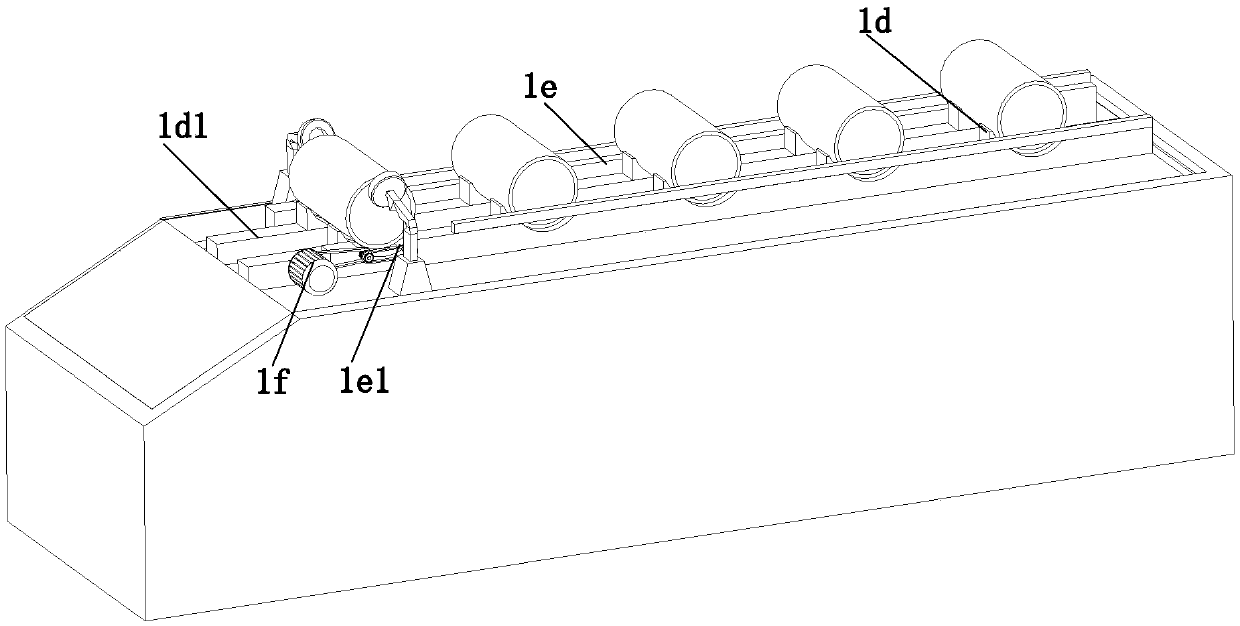

[0039] Reference Figure 1 to Figure 20 An auxiliary preparation machine for the main housing of an air-conditioning compressor is shown, including a blanking mechanism 1, a deburring mechanism 2, an inner diameter correction mechanism 3, a side hole punching mechanism 4, and a side hole trimming mechanism 5. The blanking mechanism 1 includes The first work cabinet 1a and a blanking part 1b installed in the first work cabinet 1a, the blanking part 1b is provided with a first driving part 1c for driving the main housing to be blanked to roll, the deburring mechanism 2 is installed on the first work cabinet 1a, the deburring mechanism 2 includes two deburring components 2a respectively corresponding to one end of the main housing to be deburred, and the inner diameter correcting mechanism 3 includes a first trans...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com