Construction process of secondary lifting pump house

A construction process and pump room technology, which is applied to formwork/formwork/work frame, on-site preparation of building components, connection of formwork/formwork/work frame, etc., can solve problems such as water seepage to pull bolts, Achieve the effect of ensuring thermal insulation performance, waterproof performance, and limit solution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The following is attached Figure 1-4 The application is described in further detail.

[0041] The embodiment of the present application discloses the construction technology of the secondary lifting pump room.

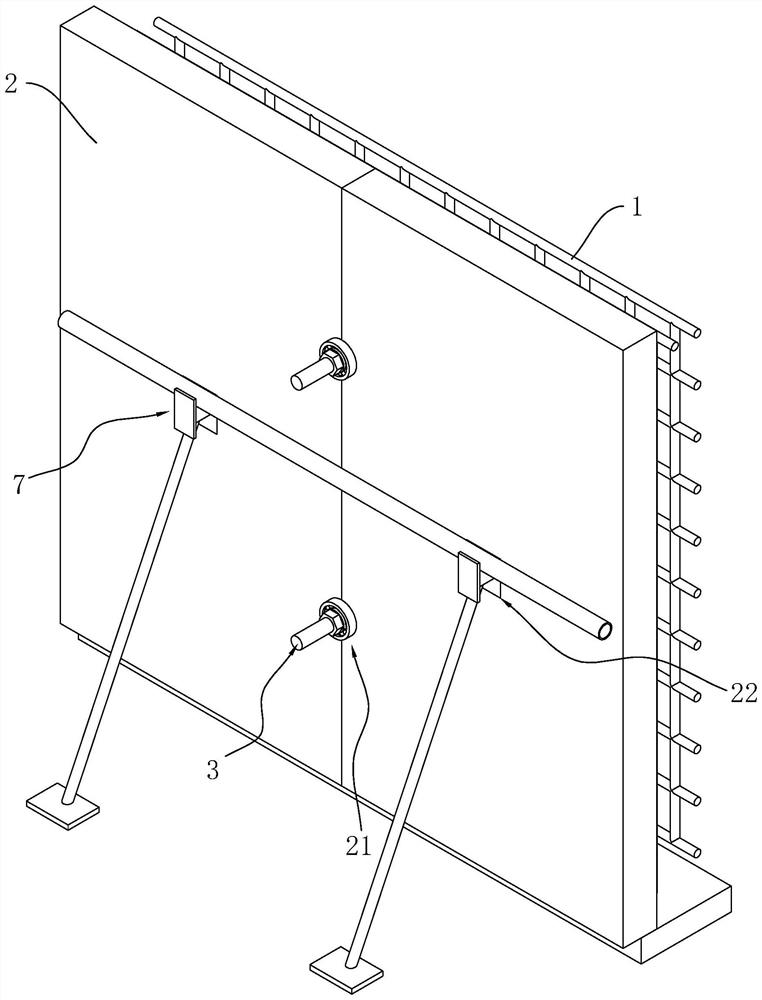

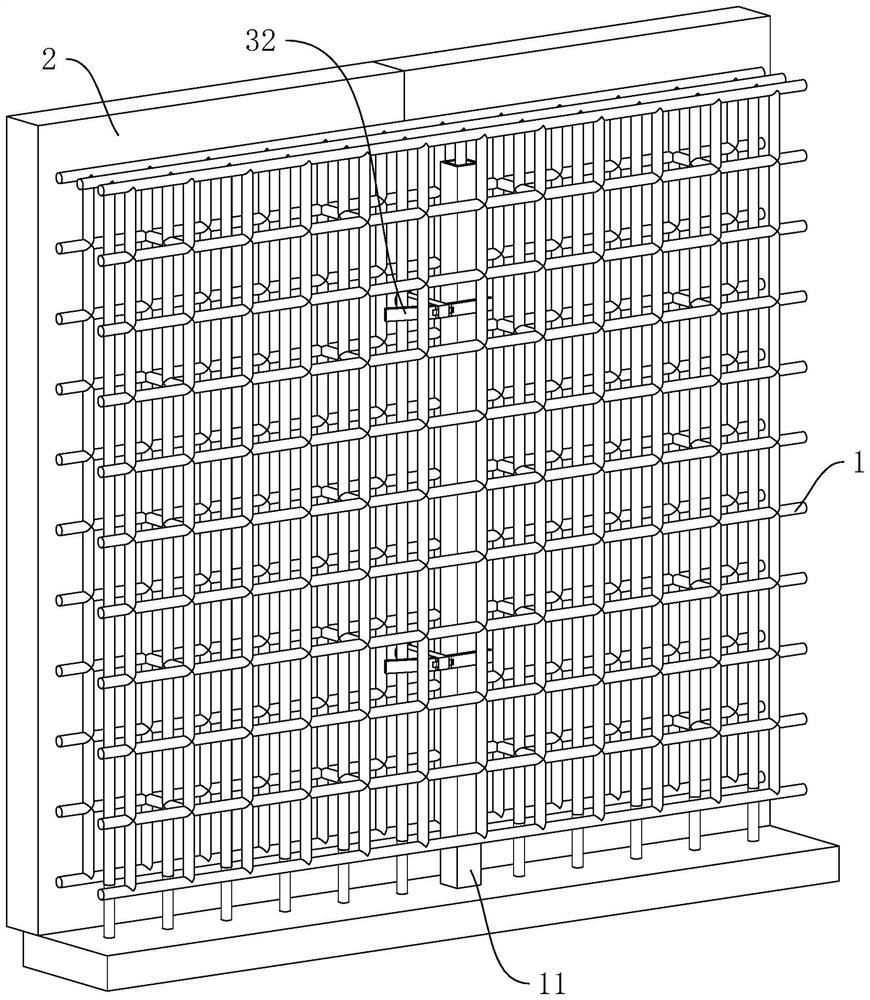

[0042] The following components are used in construction, refer to figure 1 , including a connection assembly 3 and a positioning bracket 7, the connection assembly 3 replaces the pull bolts to fix the wooden formwork 2 at a designated position. The existence of the positioning bracket 7 plays the effect of convenient construction on the supporting process of the wooden formwork 2.

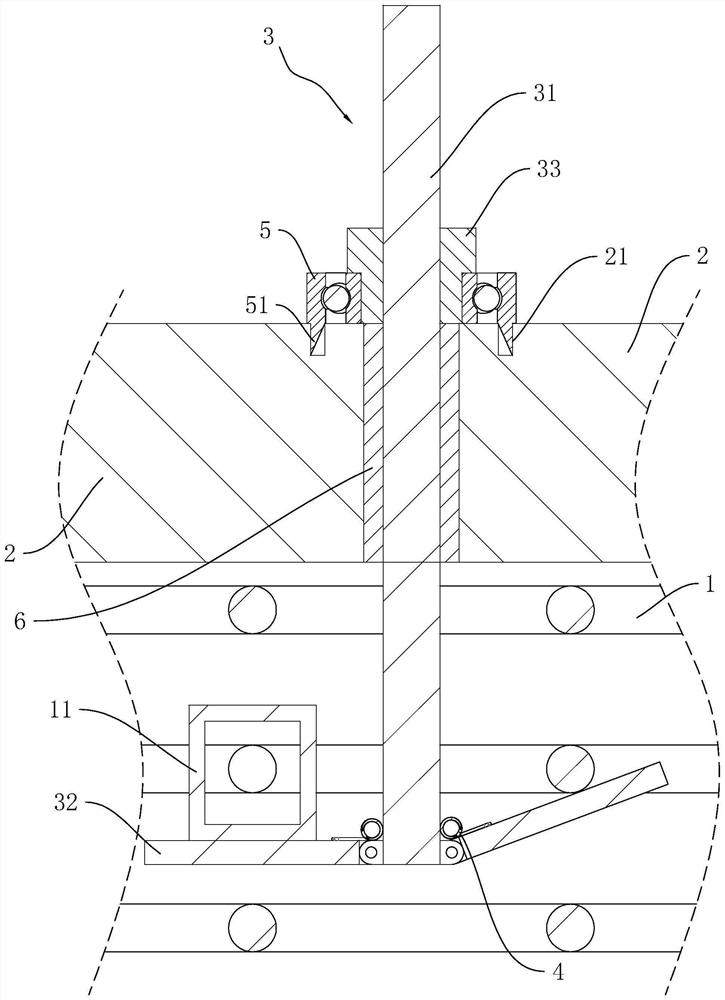

[0043] refer to figure 2 and image 3 , The connection assembly 3 includes a fixed rod 31 , a limit rod 32 and a positioning nut 33 , one end of the fixed rod 31 is hinged to one end of the limit rod 32 , and the other end is screwed to the positioning nut 33 . A torsion spring 4 is arranged between the limiting rod 32 and the fixed rod 31. One end of the torsion spring 4 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com