Split washer mounting tool

An open retaining ring and installation tool technology, applied in the direction of manufacturing tools, hand-held tools, etc., can solve problems such as unfavorable worker efficiency and product quality improvement, laborious operation by workers, and the retaining ring is not easy to reach the predetermined position at one time. Work efficiency and product quality, the effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

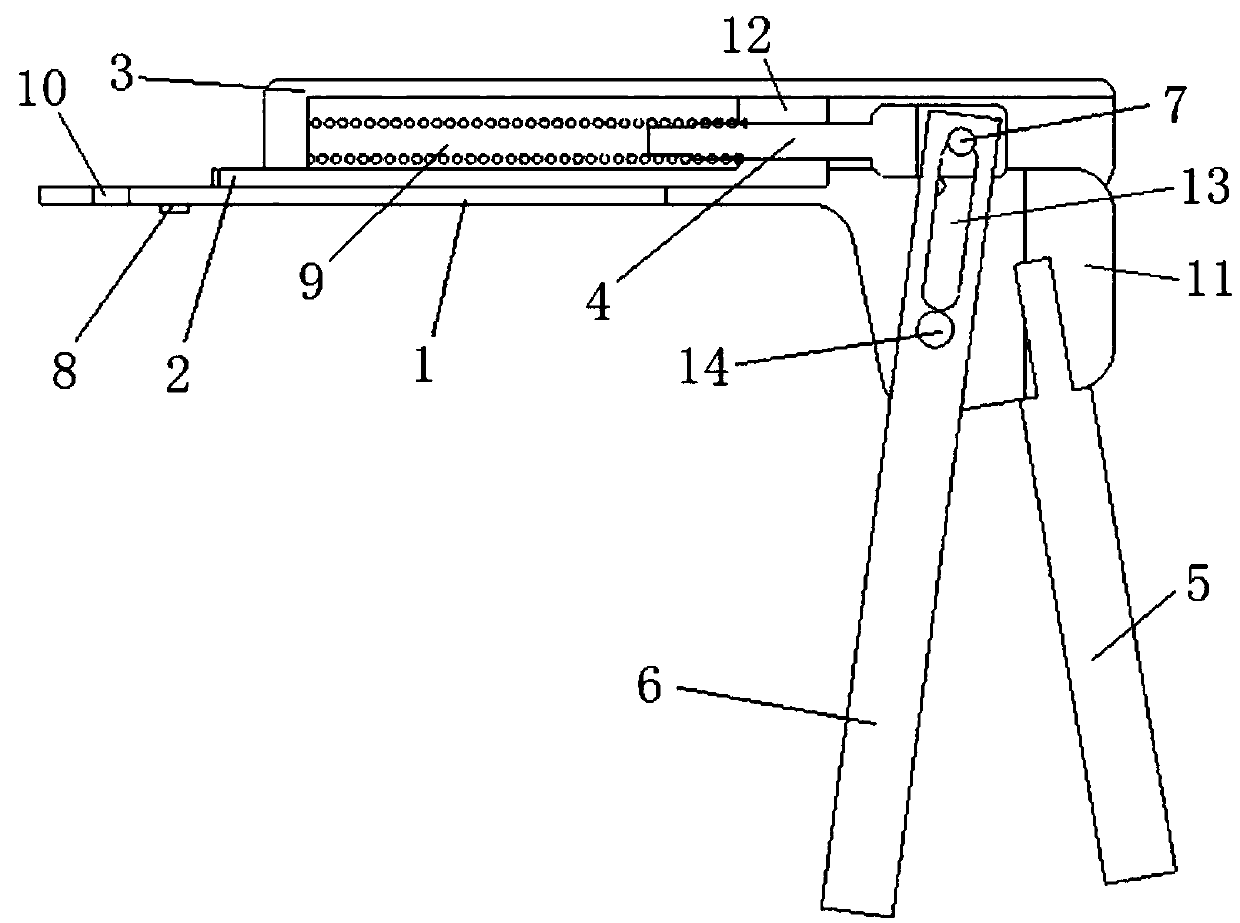

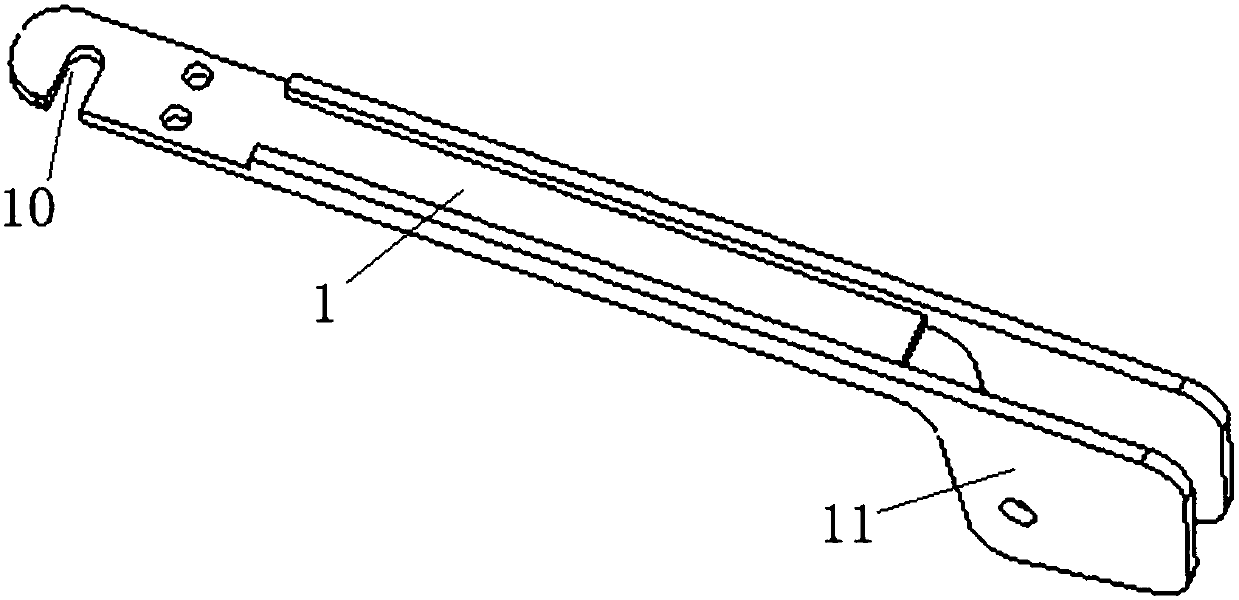

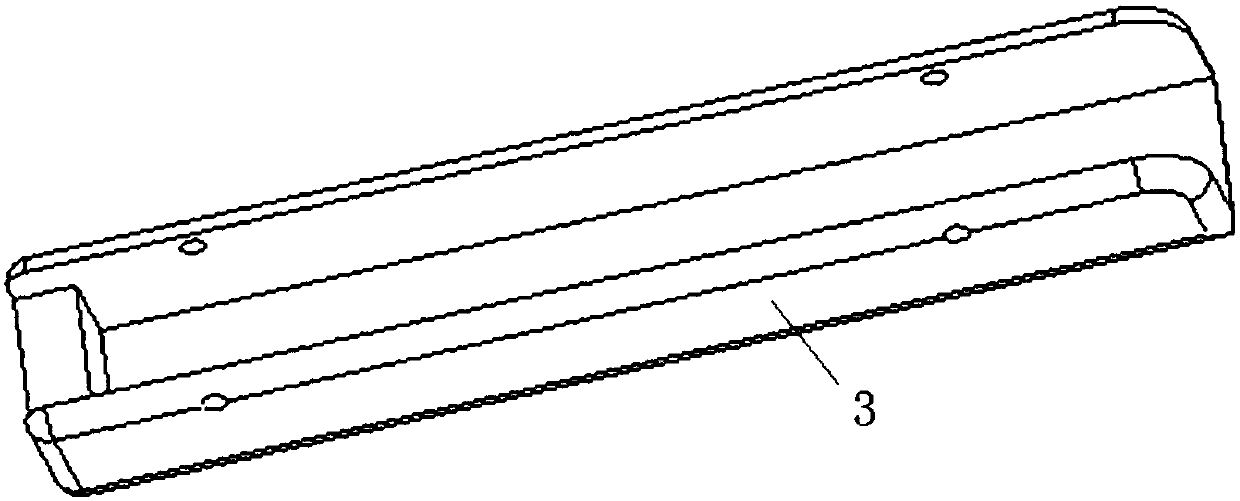

[0017] Such as Figure 1~4 As shown, the present invention includes a slideway 1, a push rod 2, a push rod cover 3, an auxiliary rod 4, a handle 5, a swing rod 6, a pin 7, a magnet 8 and a return spring 9. A U-shaped installation groove 10 for positioning the shaft part 20 is provided at the front end of the slideway 1, a magnet 8 is installed on the slideway 1 positioned behind the U-shaped installation groove 10, and a connection is integrally provided at the rear end of the slideway 1. plate 11. The push rod 2 is slidably arranged on the slideway 1 , and a stopper 12 is arranged at the rear end of the push rod 2 . The push rod cover 3 is buckled and installed on the slideway 1, and the front end of the push rod cover 3 is provided with a gap for the front end of the push rod 2 to pass through. The auxiliary rod 4 is fixedly connected with the bl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com