Patents

Literature

38results about How to "Won't lose stability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

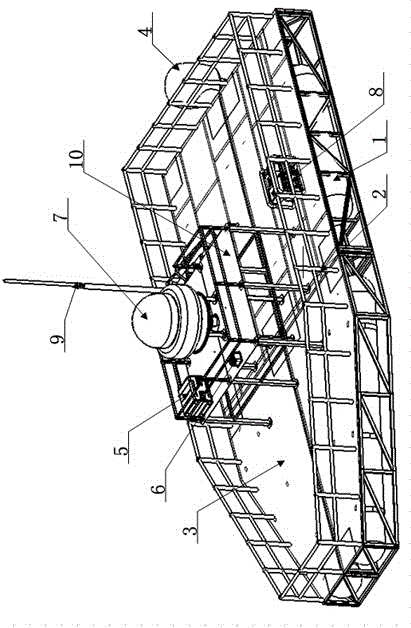

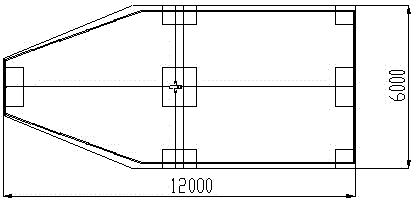

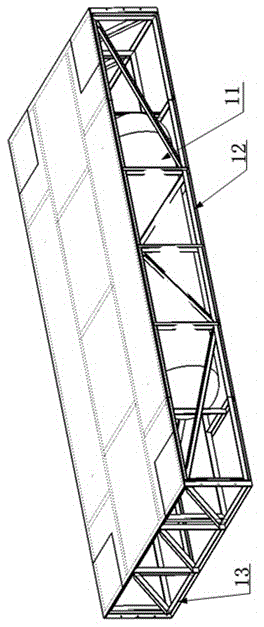

Flexible combined spliced target ship

InactiveCN104943818AThe overall design is ingeniousSimple and compact structureMovable targetsVessel salvagingMeasuring equipmentAnalog device

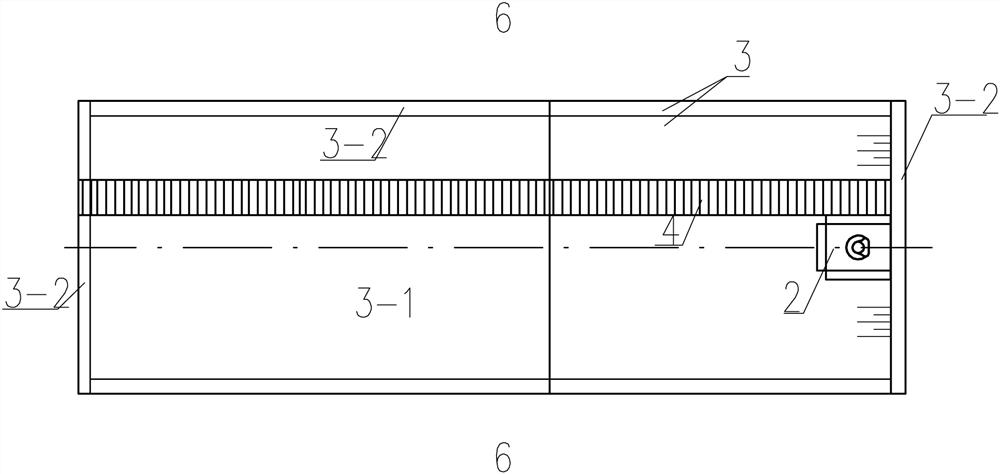

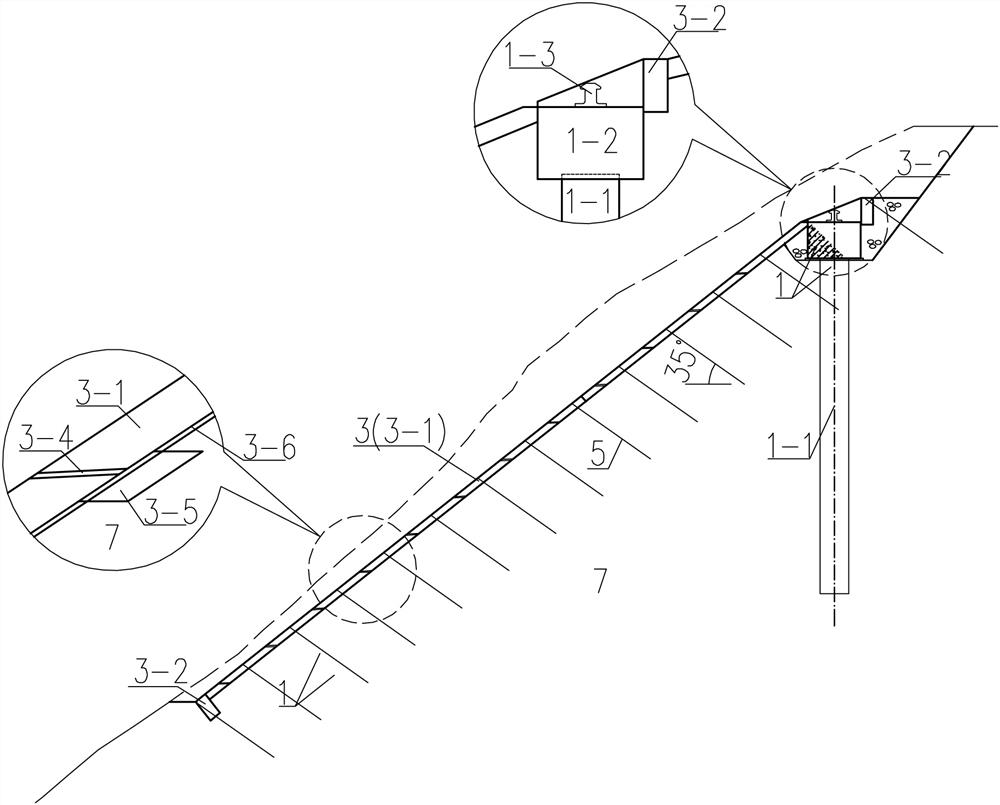

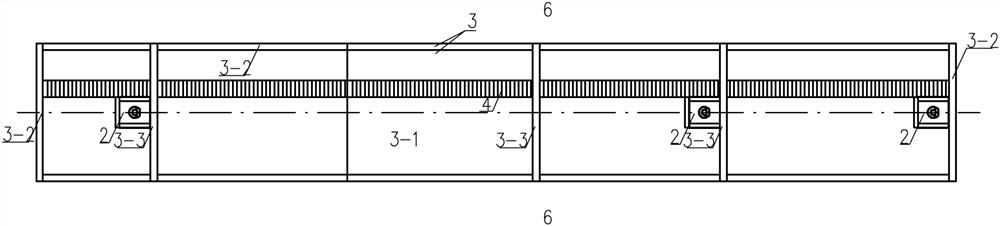

The invention relates to a flexible combined spliced target ship. The flexible combined spliced target ship is characterized in that the spliced target ship comprises a target ship platform and a ship-mounted mounting support arranged on the target ship platform, and an automatic sailing control device, a sailing attitude measuring device, a wireless communication device and a radar radiation source / interference source simulation device are arranged on the ship-mounted mounting support. The target ship is formed by splicing buoyancy units with the unified structural specification flexibly, target ship platforms of different structural scales can be formed by flexibly combining different numbers of buoyancy units, and the target ship has good structural expansibility, is suitable for the target simulation requirements for flexible and various scales and has good split transport capacity and anti-strike capacity.

Owner:NANJING CHANGFENG AEROSPACE ELECTRONICS SCI & TECH

Non-excavation type laying construction method of large-pipe-diameter pipeline of heat supply network

ActiveCN110778272AIncrease workloadEasy to weldDirectional drillingFlushingStructural engineeringPipe

The invention discloses a non-excavation type laying construction method of a large-pipe-diameter pipeline of a heat supply network. The method comprises the steps that drilling machine equipment is selected, the pull strength of a selected horizontal directional drilling machine needs to meet the requirement of the directional drilling penetration length, the pull strength is larger than or equalt 3*(the friction resistance generated by the pipeline in a hole and the viscous comprehensive friction resistance of the pipeline in the hole), 3 times of the safety coefficient is taken, and mud preparing, guide hole drilling, hole pre-expanding, pipe penetration treatment and pulling back are carried out. Compared with the pipe jacking construction manner, the method has the following advantages that long-distance uninterrupted penetration construction of the pipeline can be met, and the construction speed is high; destroy to the ground environment can be reduced, and the requirement of environment protection can be met; the method is not disturbed by uncertain factors such as the soil property, underground water and underground hidden pipelines, the procedures of work well construction and work pipe penetration are omitted, and time is saved; and long-distance welding and heat preservation can be carried out on the work pipe on the ground, the penetration depth is large, and the risk such as water penetration and pipe floating during river penetration is avoided.

Owner:POWER CHINA HENAN ENG CO LTD

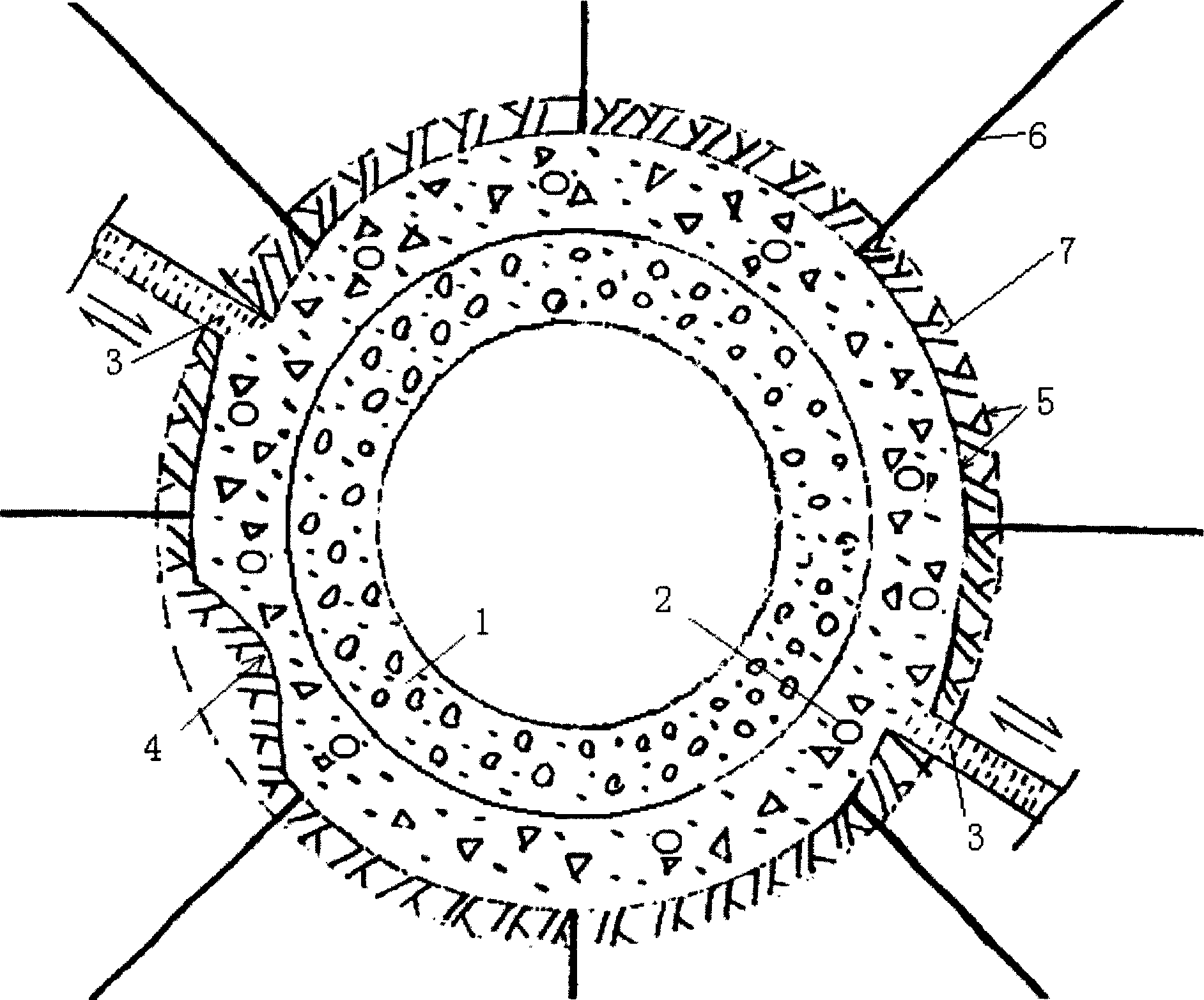

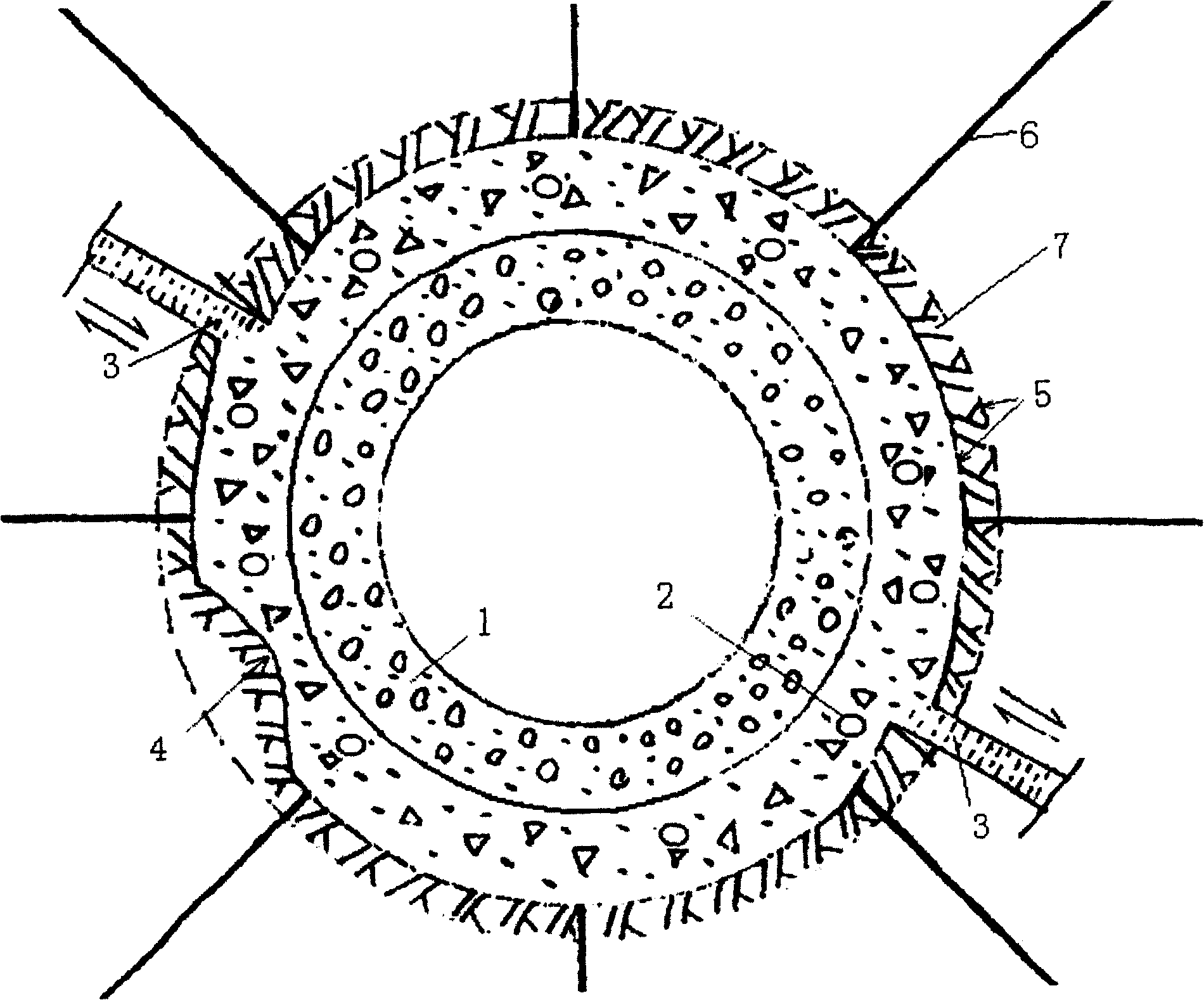

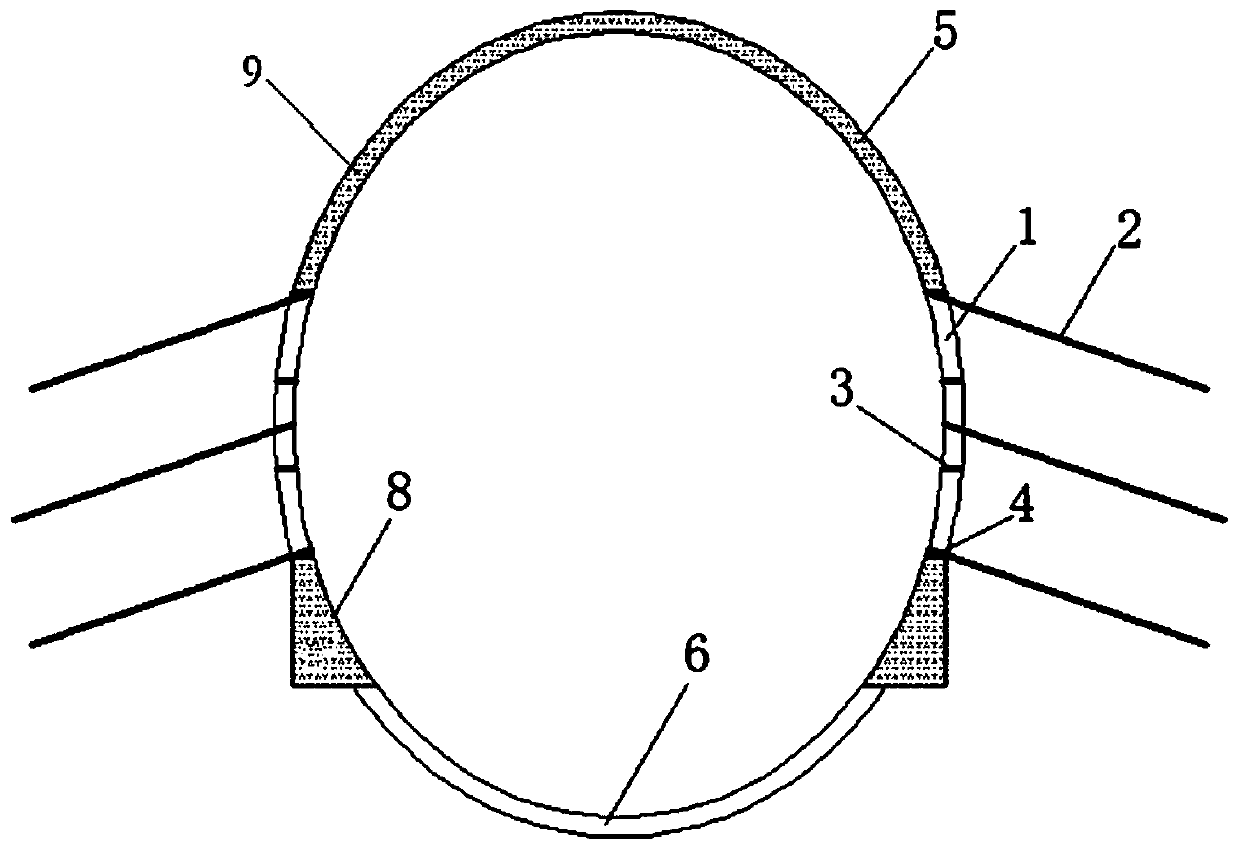

Composite lining suitable for surrounding rock after-deformation

InactiveCN1710252AWon't lose stabilityWon't breakUnderground chambersTunnel liningSoft layerEngineering support

The invention relates to a complex lining adaptive to the great deformation of adjacent rock, relating to underground engineering supporting structure. To resolve the problem that existing linings is no suitable for the evening converge and fracture deformation, the invention discloses a complex lining which includes inner layer and outer layer, the inner layer is concrete layer of thickness 30 to 200 cm and is a rigid layer, the outer layer is a filling layer filled with dirt, rock, sand, and water with a thickness of 30 -150 cm, and is a soft layer. The complex lining adapts the fracture deformation with its deformable outer layer while providing proper support to the adjacent rock protecting inner layer and supporting adjacent rock to stabilize the rock.

Owner:NANJING HYDRAULIC RES INST THE MINISTRY OF WATER RESOURCES THE MINIST

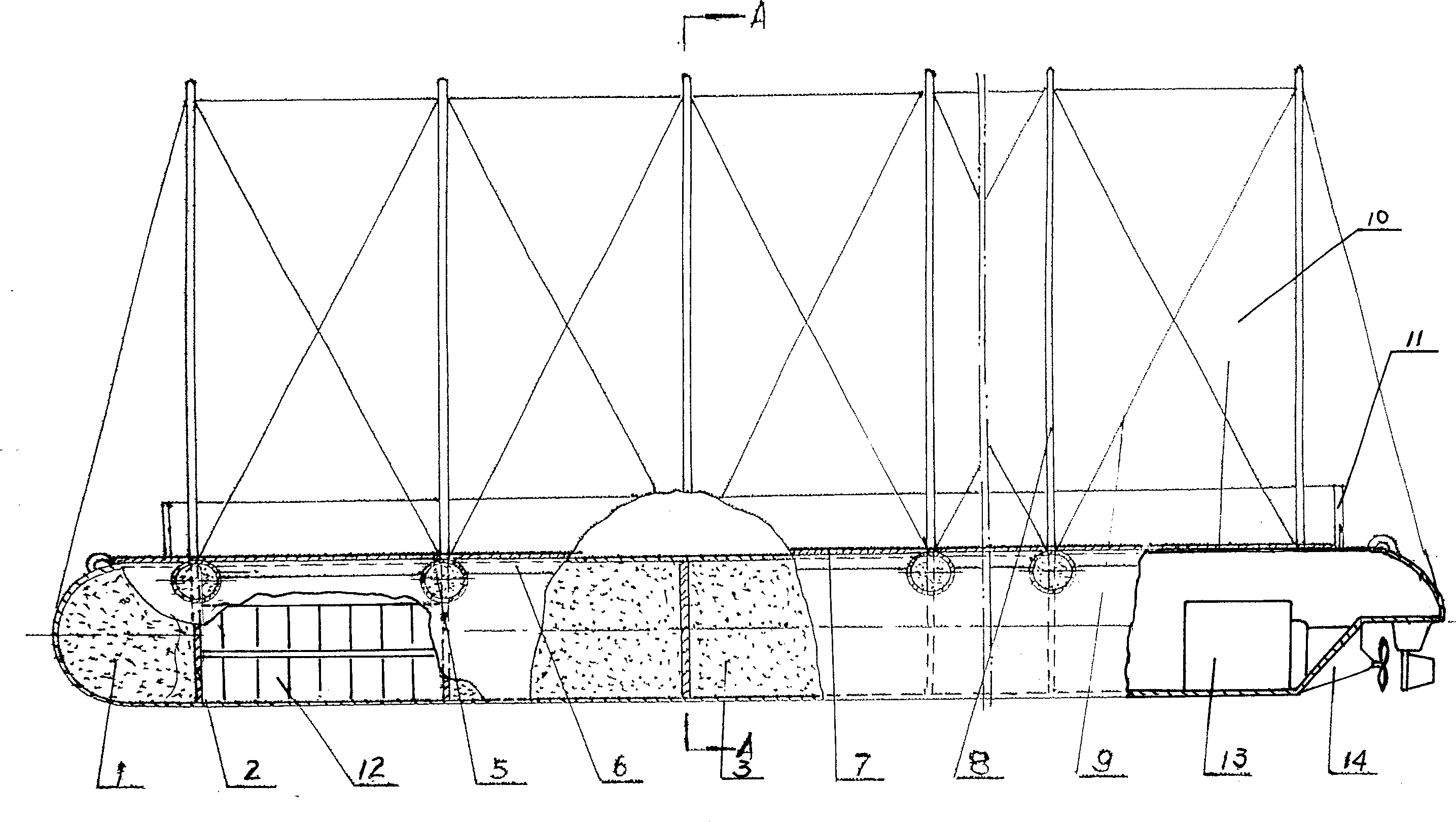

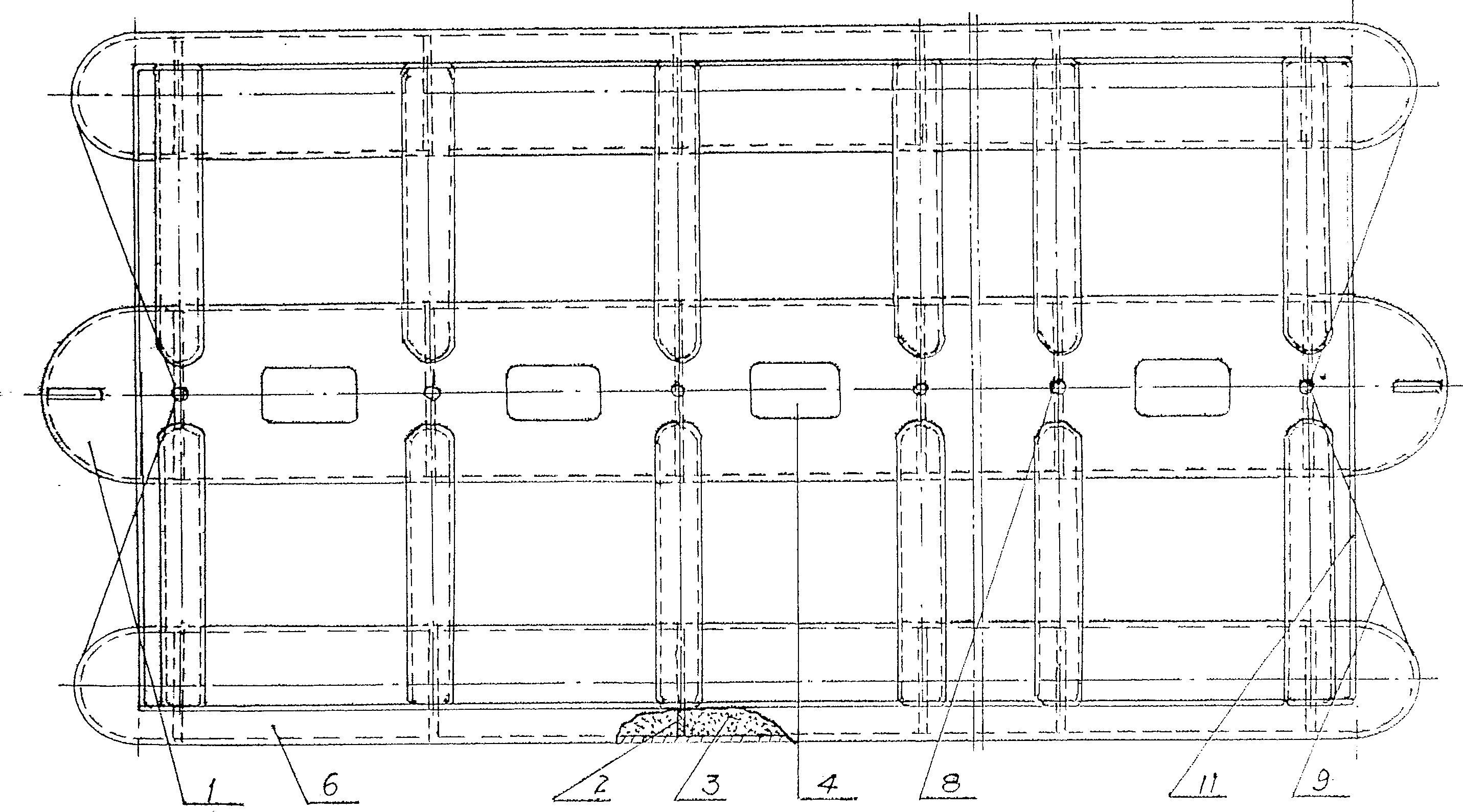

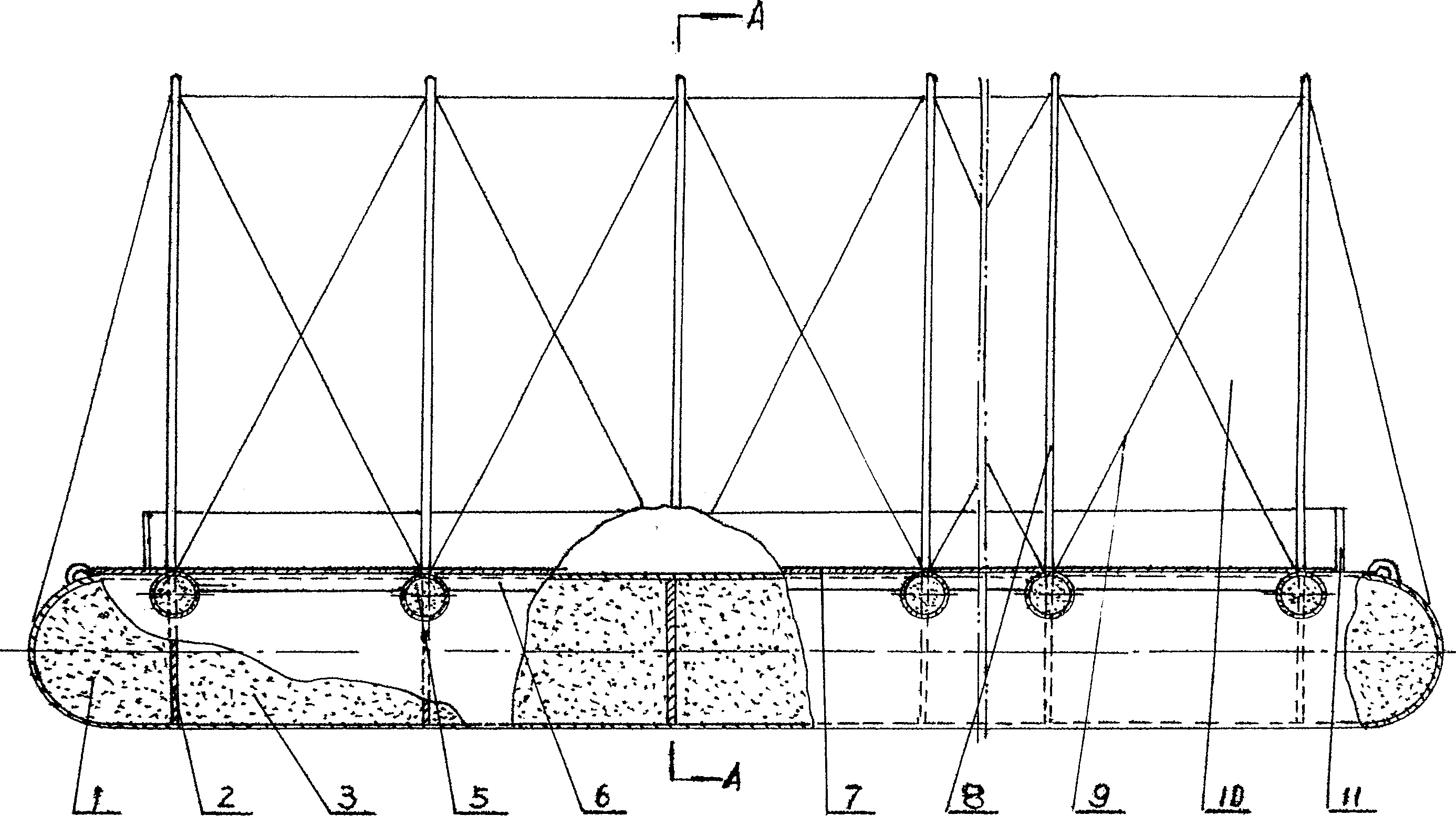

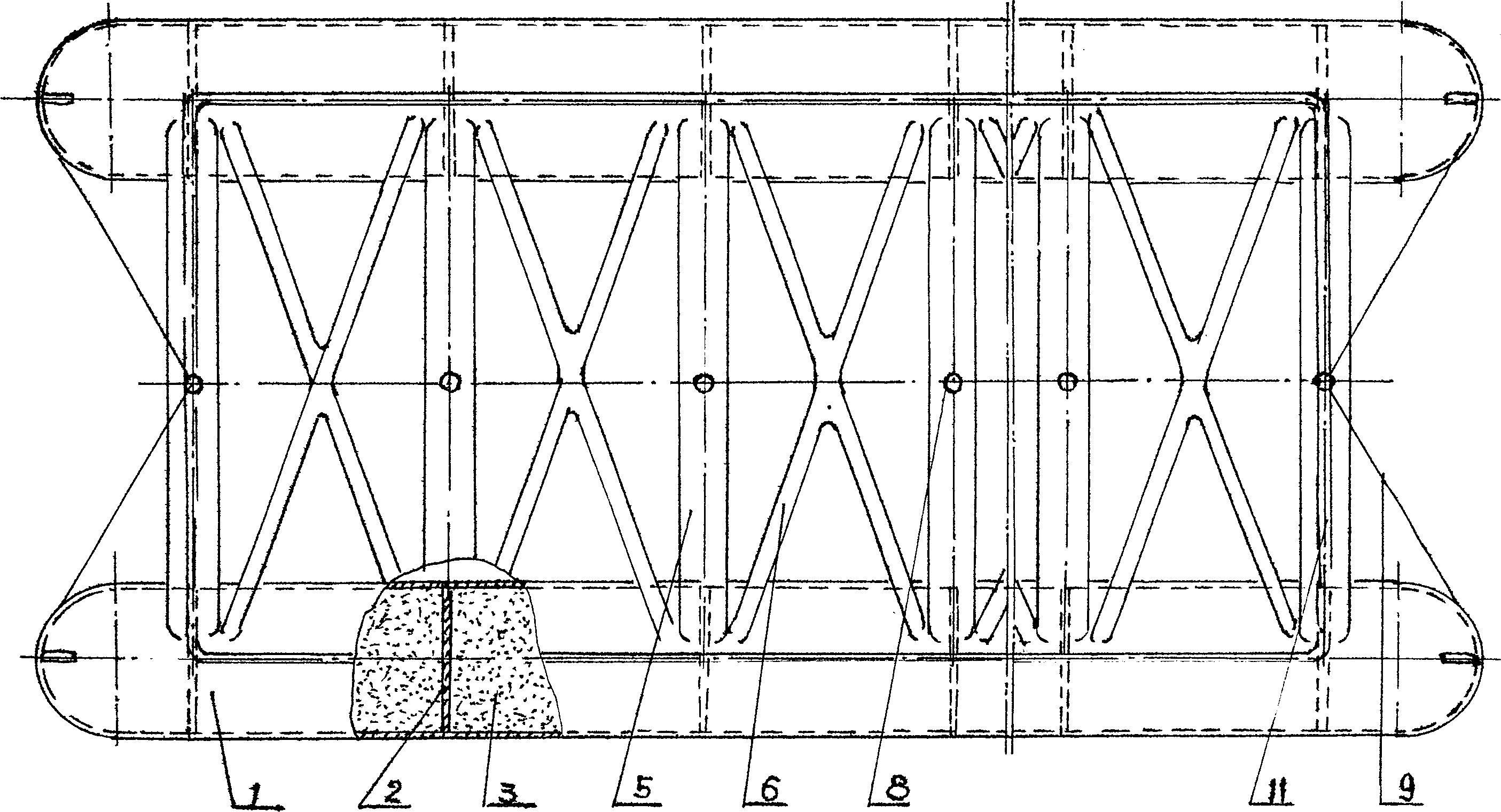

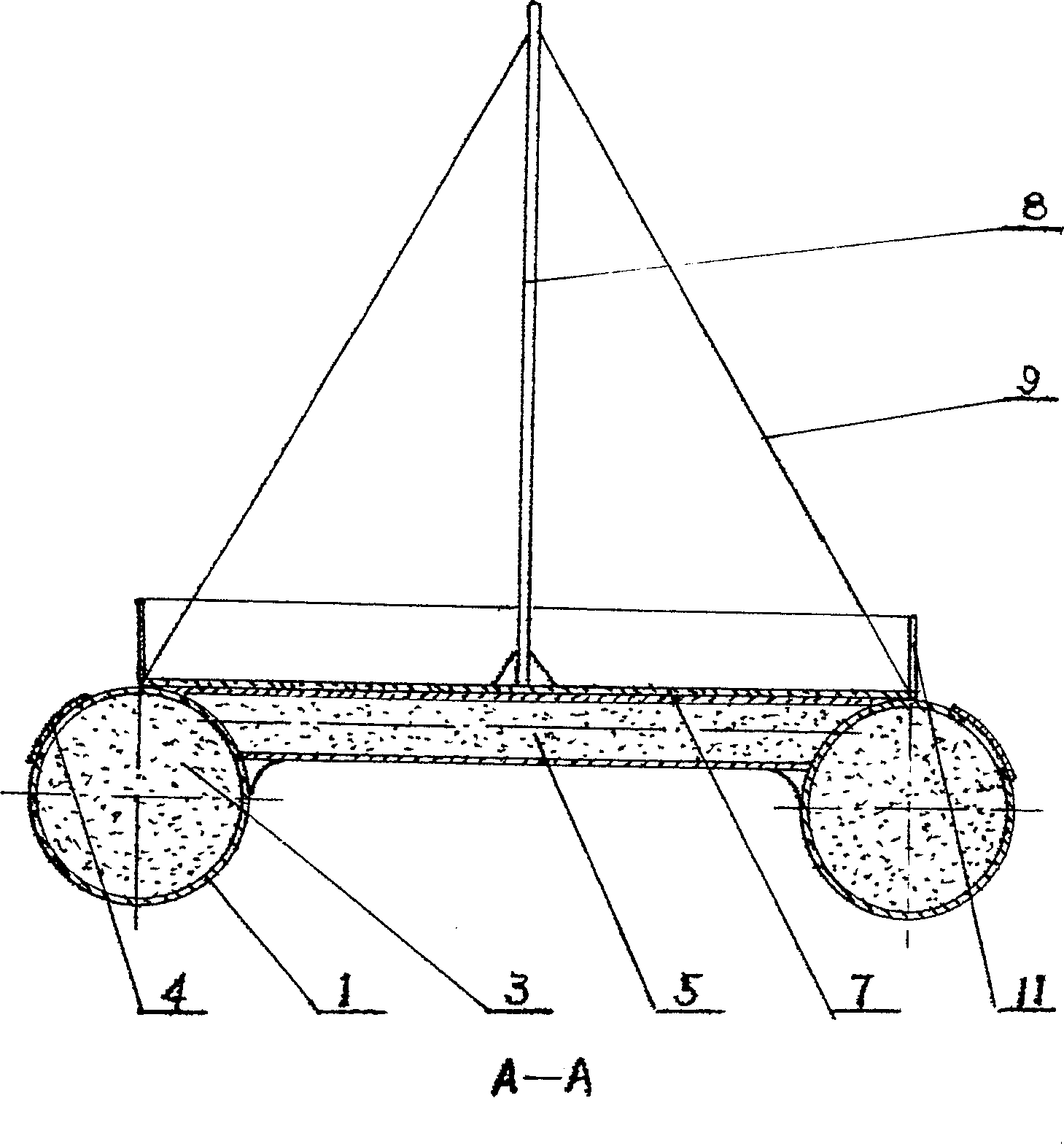

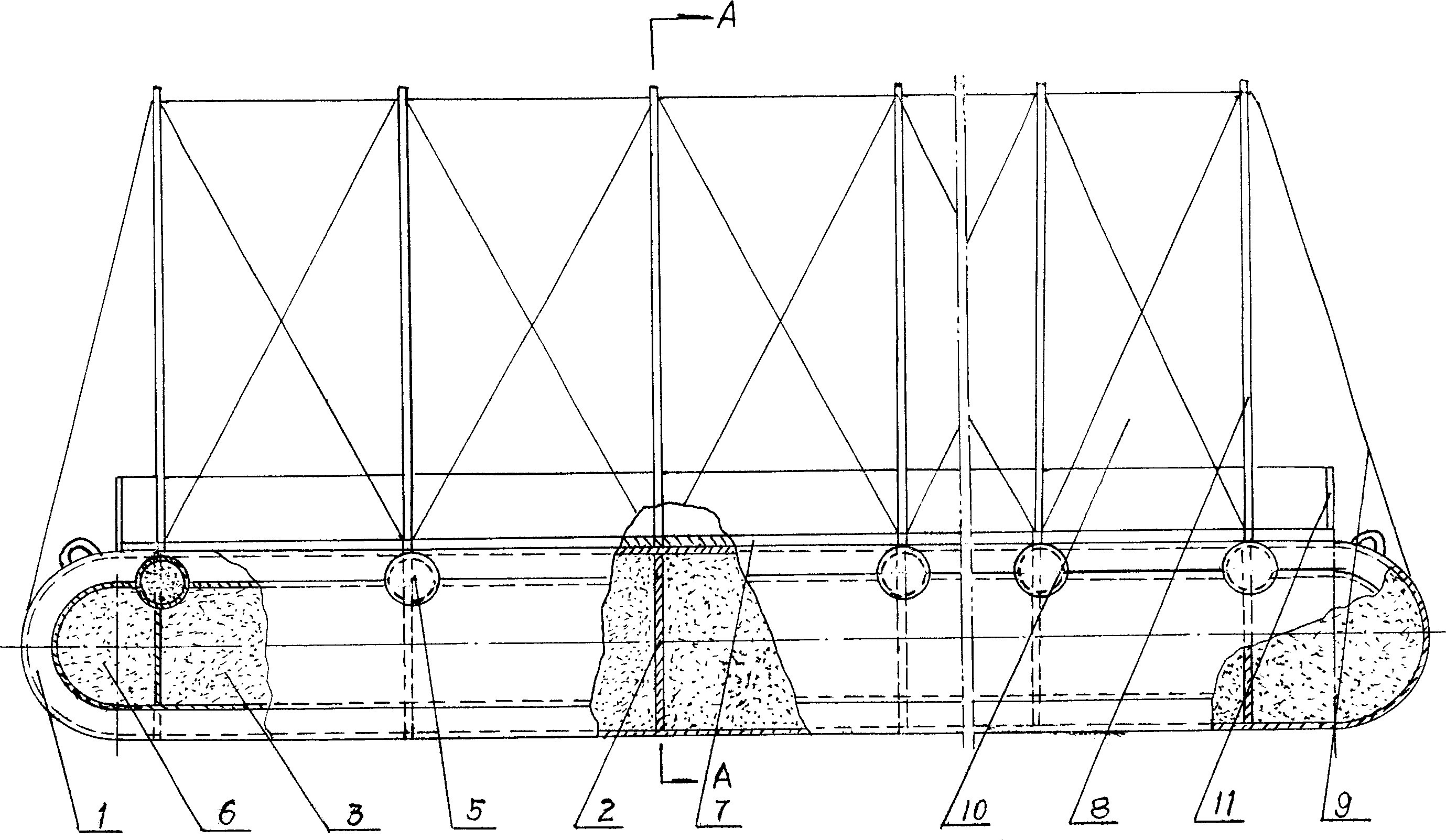

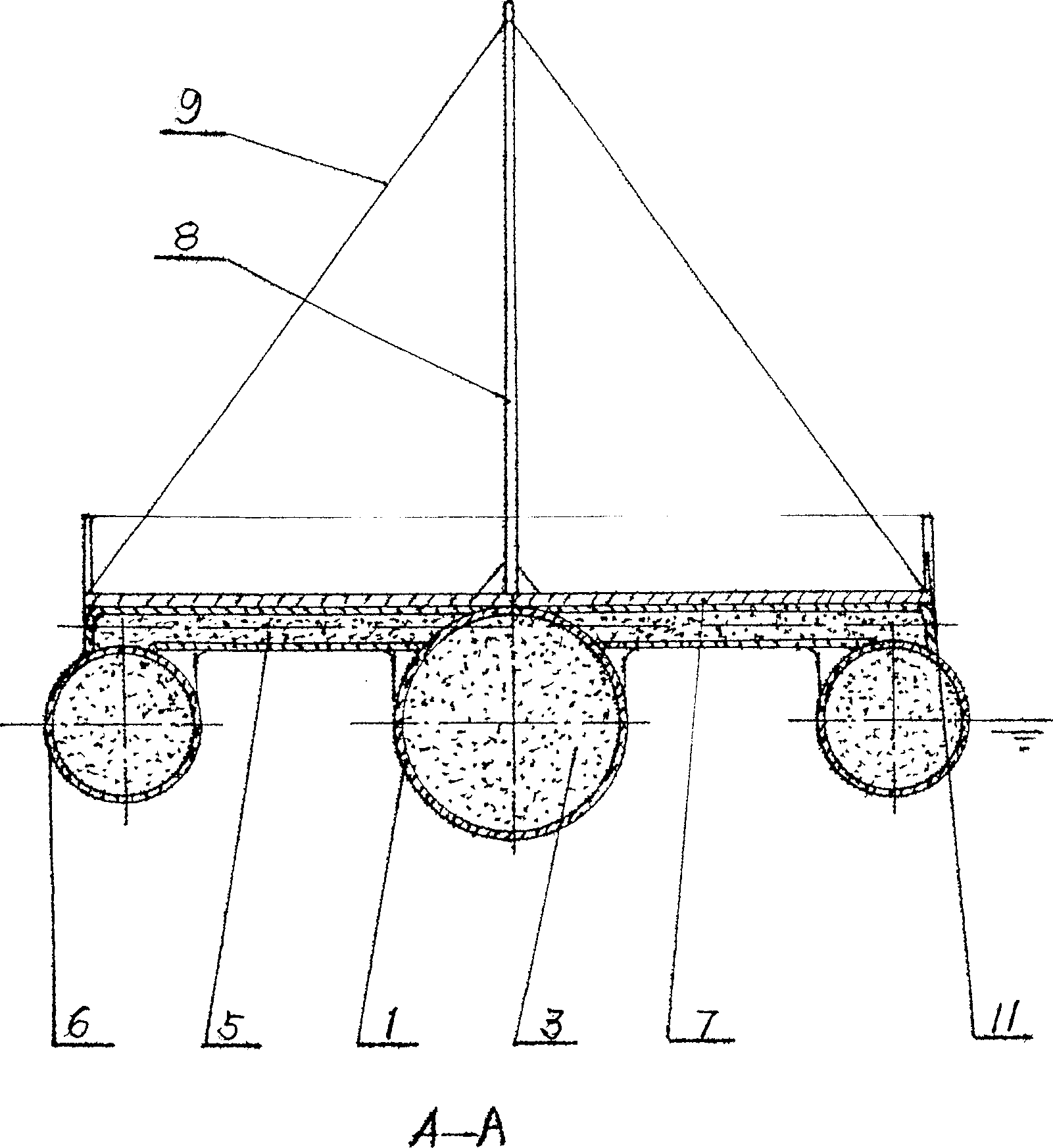

Double-body target ship with float structure and power device

InactiveCN1428589AImprove anti-strike abilityImprove impact resistanceWaterborne vesselsMovable targetsPropellerWood panel

The double-body target ship whose float structure has power device is characterized by that it has two parallel-arranged slender round tubular ship bodies with round end, in the ship body there are partions for separating the ship body into mutually separated buoyancy tanks which are filled up with light foamed material, every ship body is respectively equipped with a power device, and said power device includes engine, propeller, rudder and remote control device. The upper portion of two ship bodies has the connecting deck for connecting two chip bodies, and said connecting deck is formed from deck tube, deck tube oblique drawbar and deck working surface, on the deck working surface the mast, standing rope and rail are set, and the deck tube is filled up with light foamed material.

Owner:刘红静

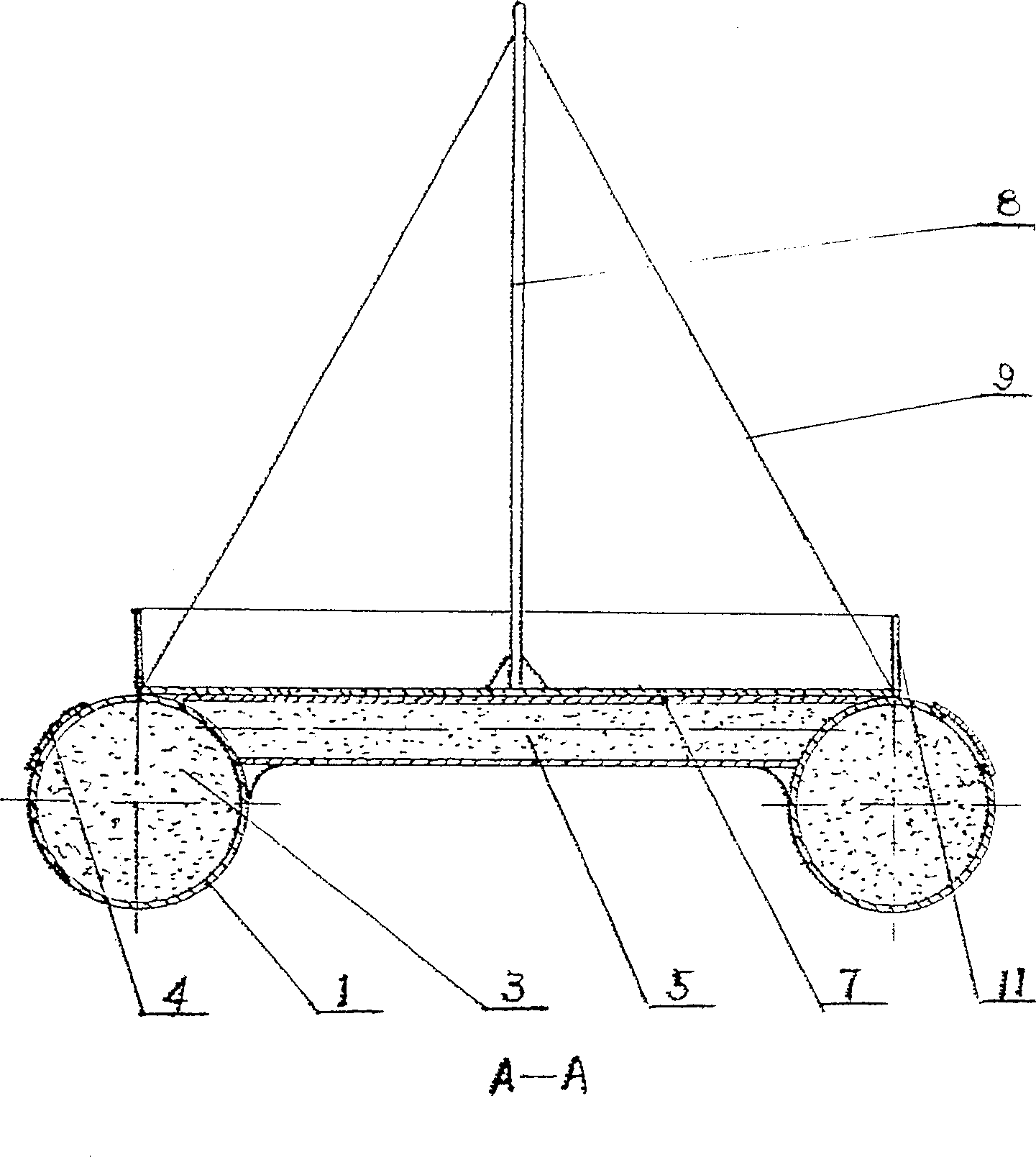

Three-body target ship with float structure and power device

InactiveCN1428590AImprove impact resistanceWon't lose stabilityWaterborne vesselsMovable targetsPropellerRudder

Two sides of main ship body of three-body target ship whose float structure has power device are equipped with a parallelly-arranged auxiliary ship body respectively, the upper portion of the main ship body and auxiliary ship body has the connecting deck, and in the main ship body and auxiliary ship body there are partitions for separating the main ship body and auxiliary ship body into mutually-separated buoyancy tanks which are filled up which light foamed material. In the main ship body a set of power device is set, and the power device includes engine, propeller, rudder and remove control device, and said connecting desk is formed from deck tube and deck working surface, and on the deck working surface the mast, standing rop and rail are set. Said ship adopts float structure, so that its anti-hitting power can be greatly raised.

Owner:刘红静

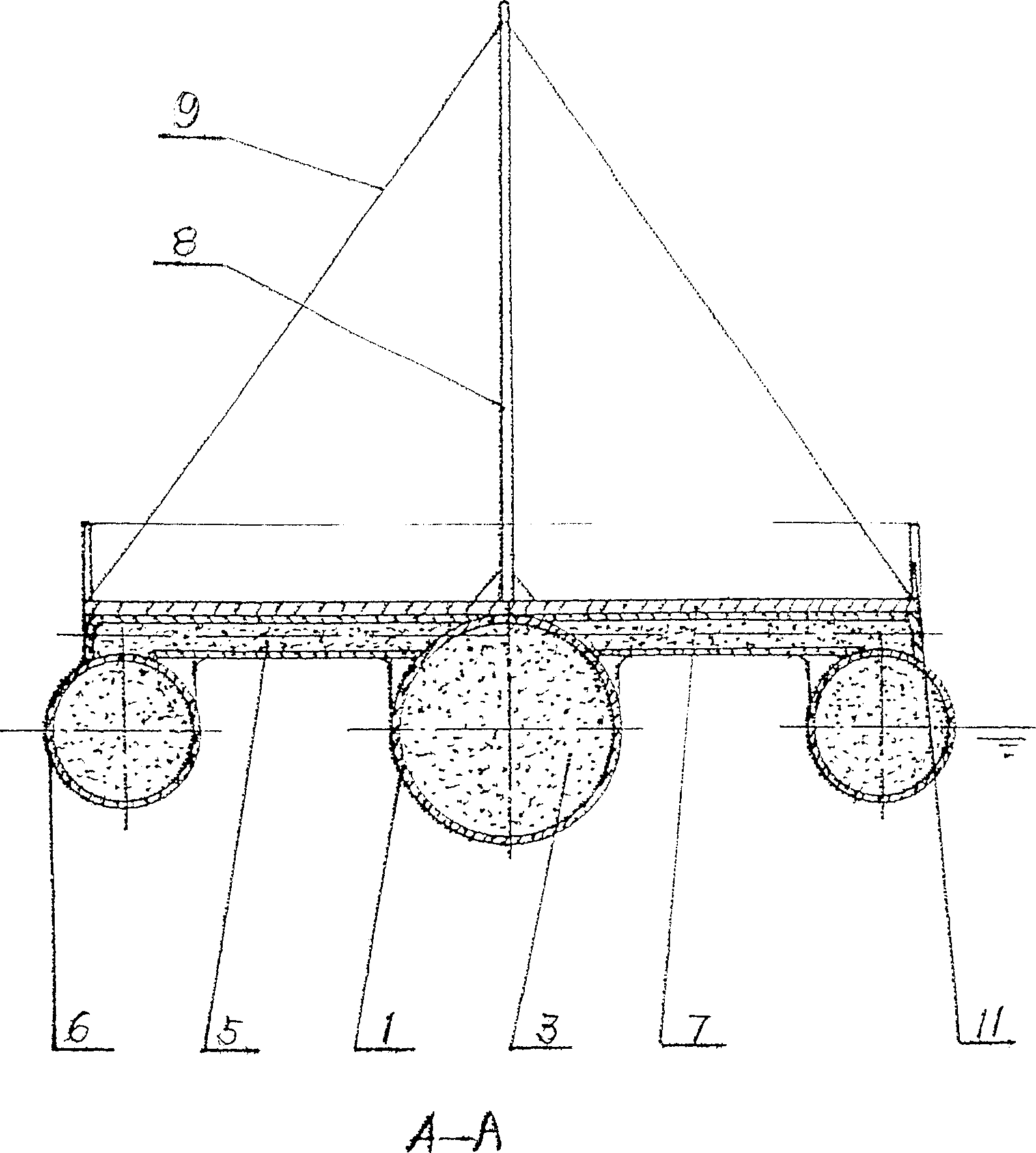

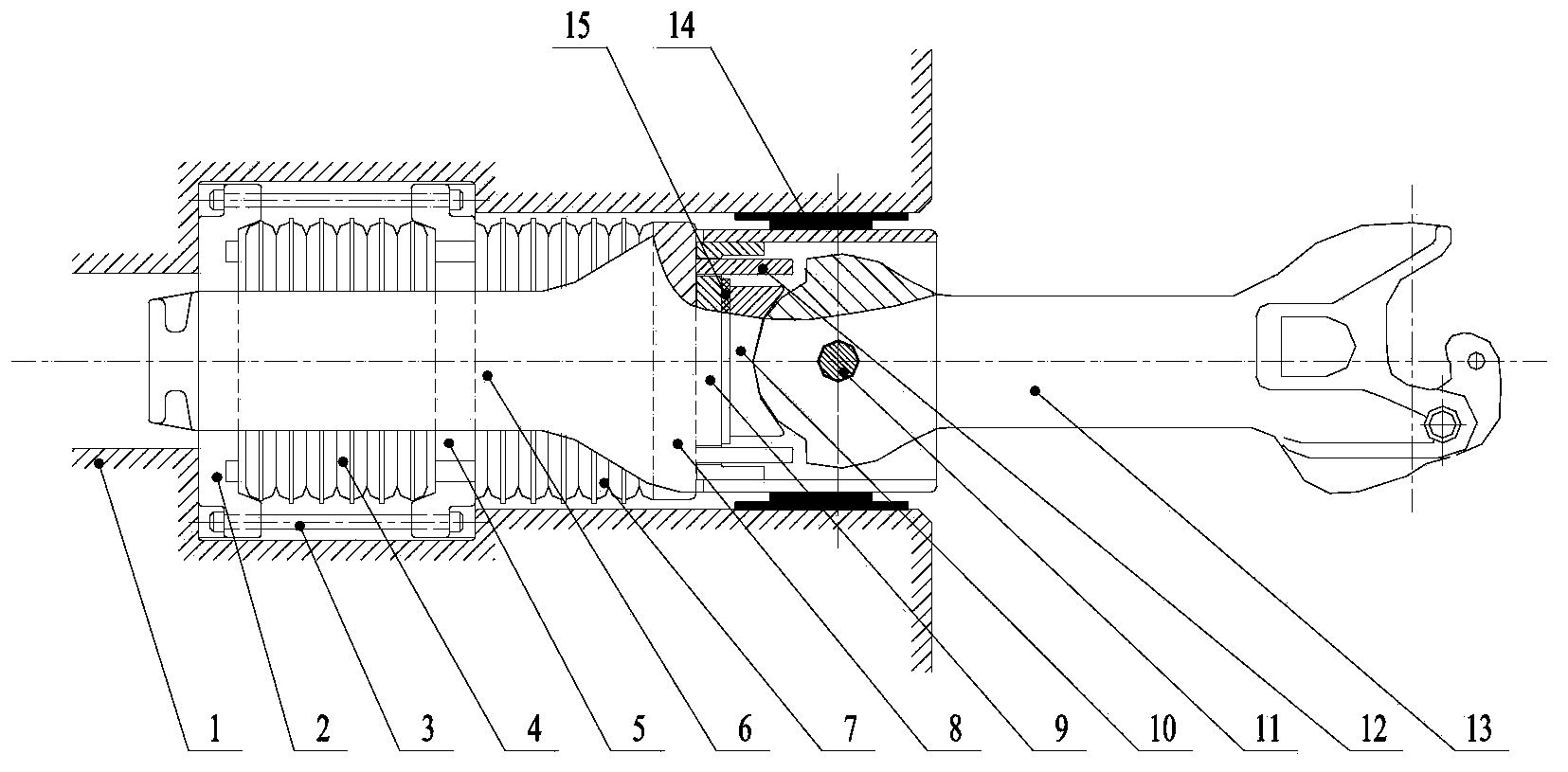

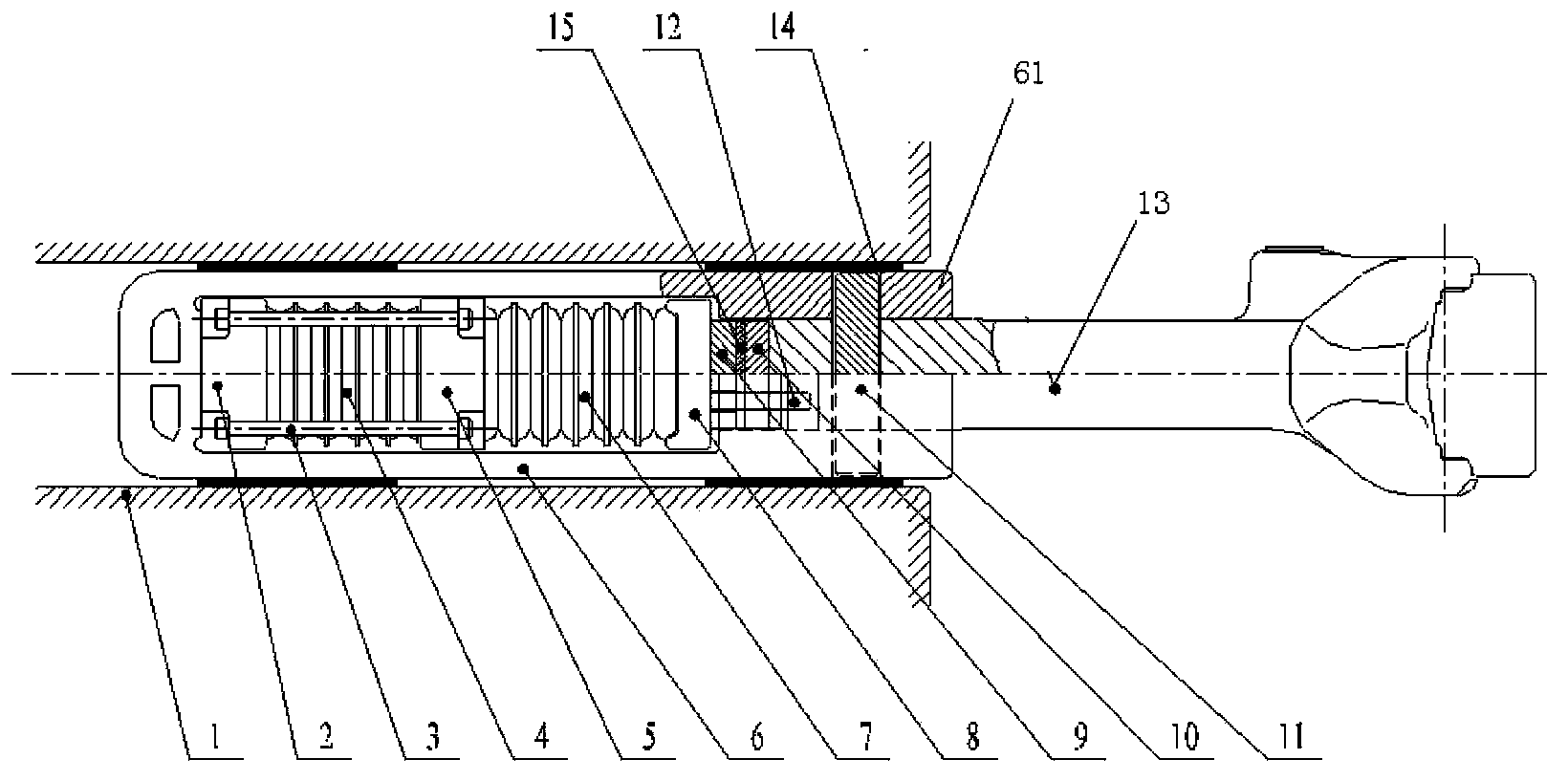

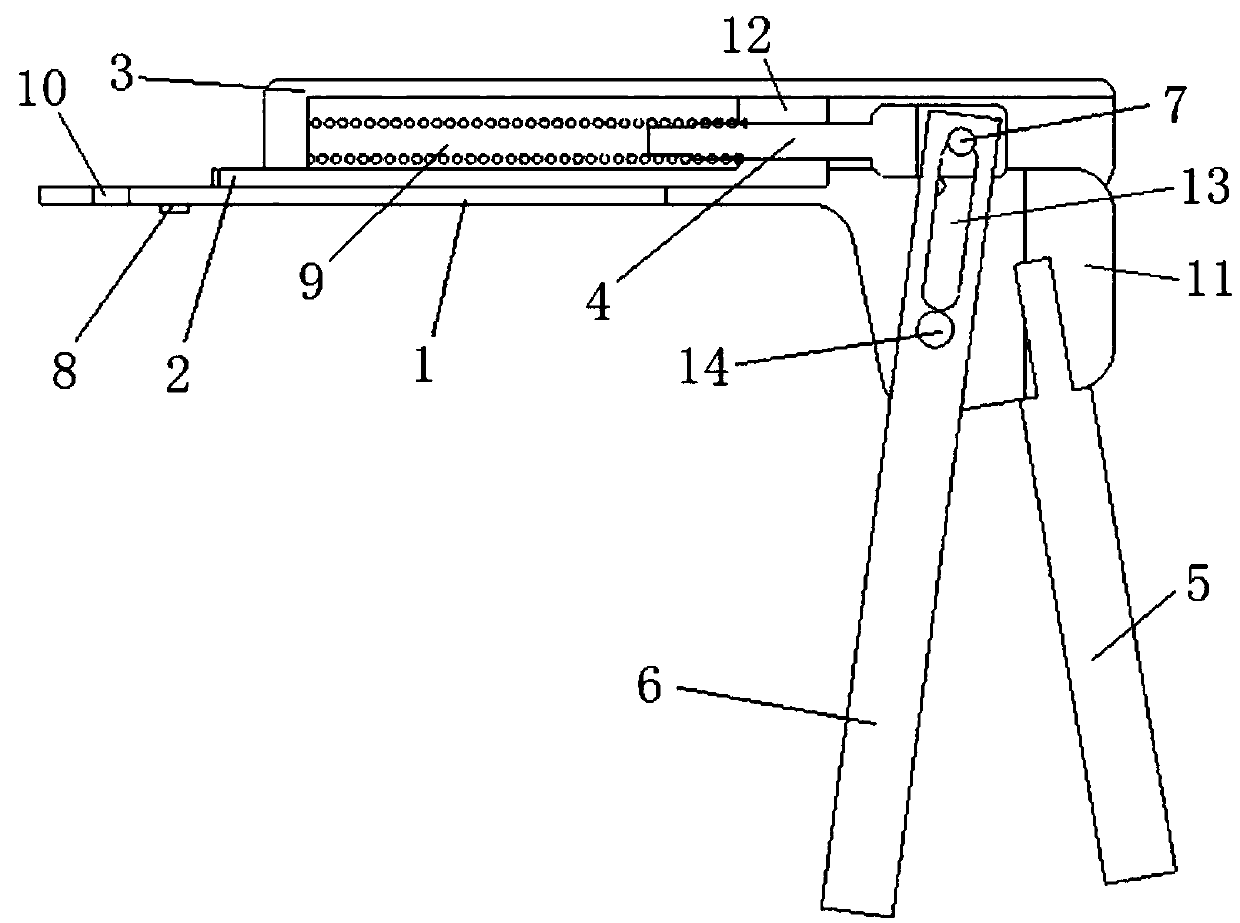

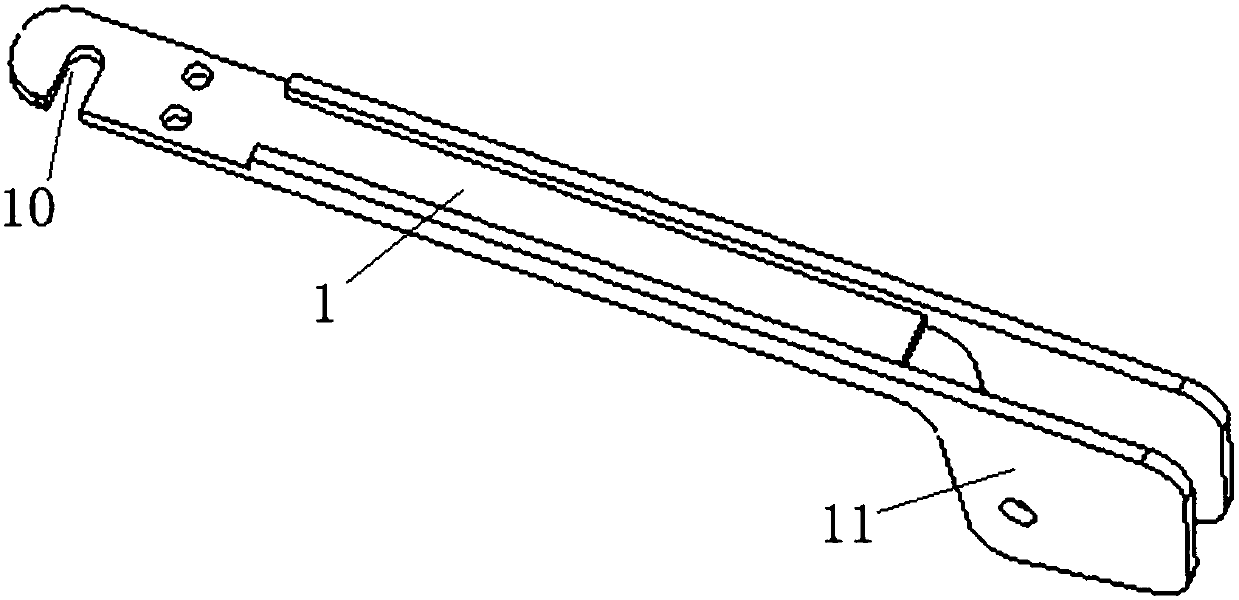

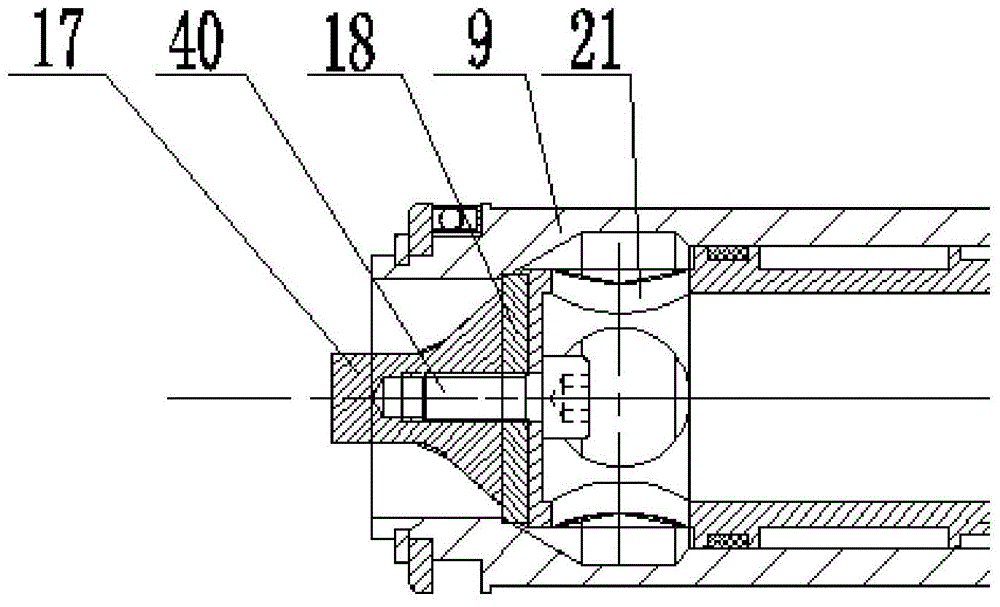

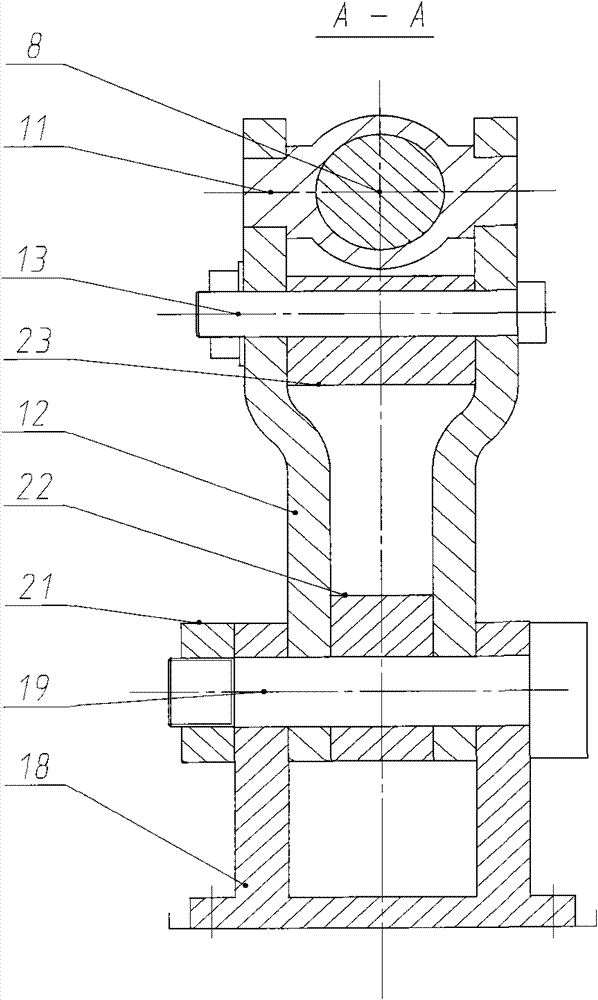

Heavy-load coupler with safety stop and low transverse force properties

The invention discloses a heavy-load coupler with safety stop and low transverse force properties. The heavy-load coupler comprises a coupler, a coupler buffer device and a coupler tail key connection mechanism. The coupler buffer device fixedly mounted on a vehicle mounting seat (1) comprises a two-stage buffer structure. The coupler (13) is connected with a coupler tail frame (6) by a coupler tail key (11) via a key hole formed in a coupler tail frame edge (61), and can rotate around the coupler tail key (11); a slider (9) and a front follower (10) are sequentially arranged between a top partition plate (8) and the coupler (13), and the slider (9) is placed in the coupler tail frame (6) and can axially slide along the coupler tail frame (6); the front follower (10) can transversely move relative to the coupler tail frame edge (61). Contact surfaces of the front follower and the tail end of the coupler are arc surfaces. The heavy-load coupler has the advantages that the coupler generates low transverse force at a small corner, and the safety of a locomotive is guaranteed when the coupler turns around a large corner.

Owner:SOUTHWEST JIAOTONG UNIV

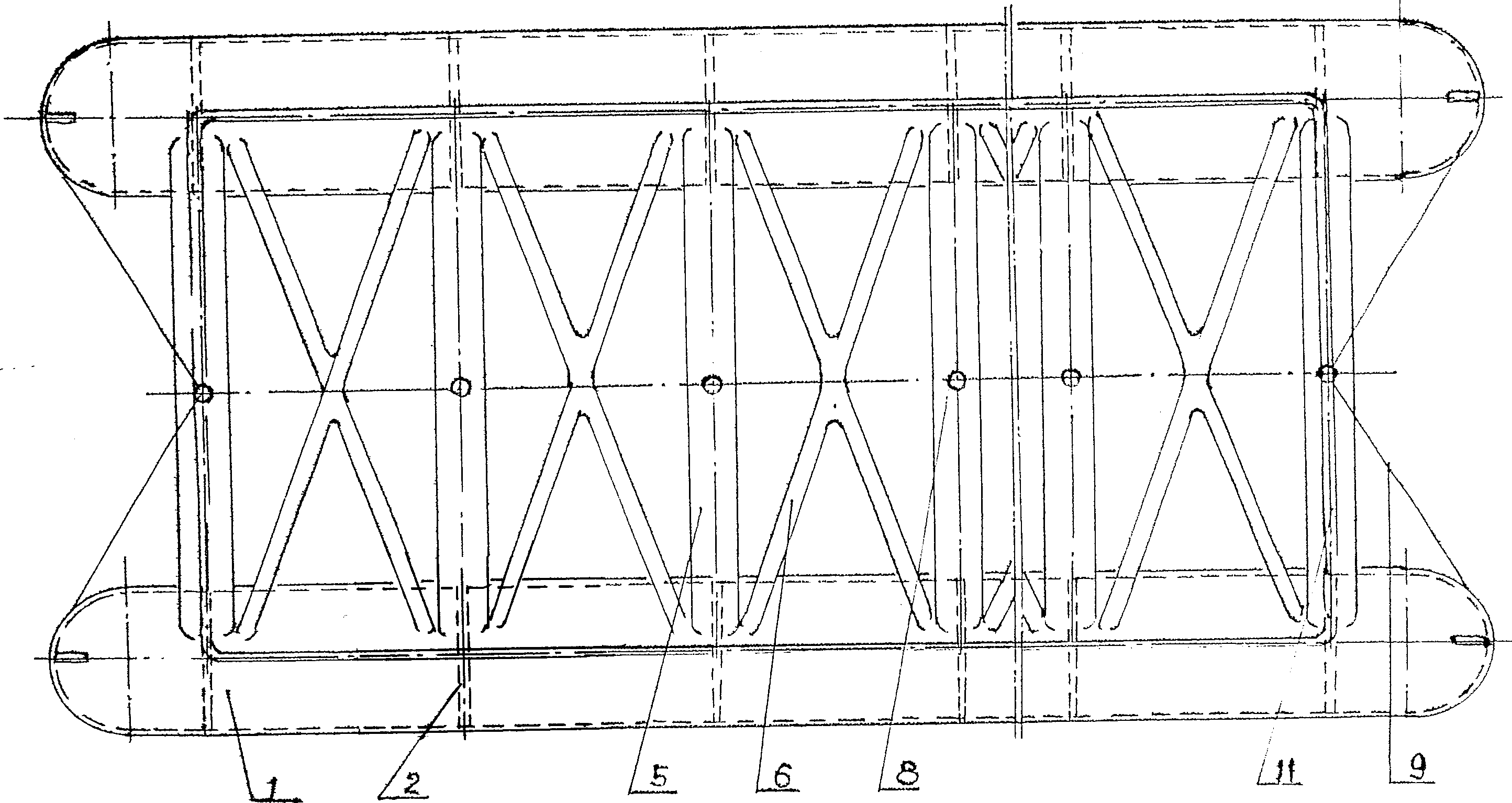

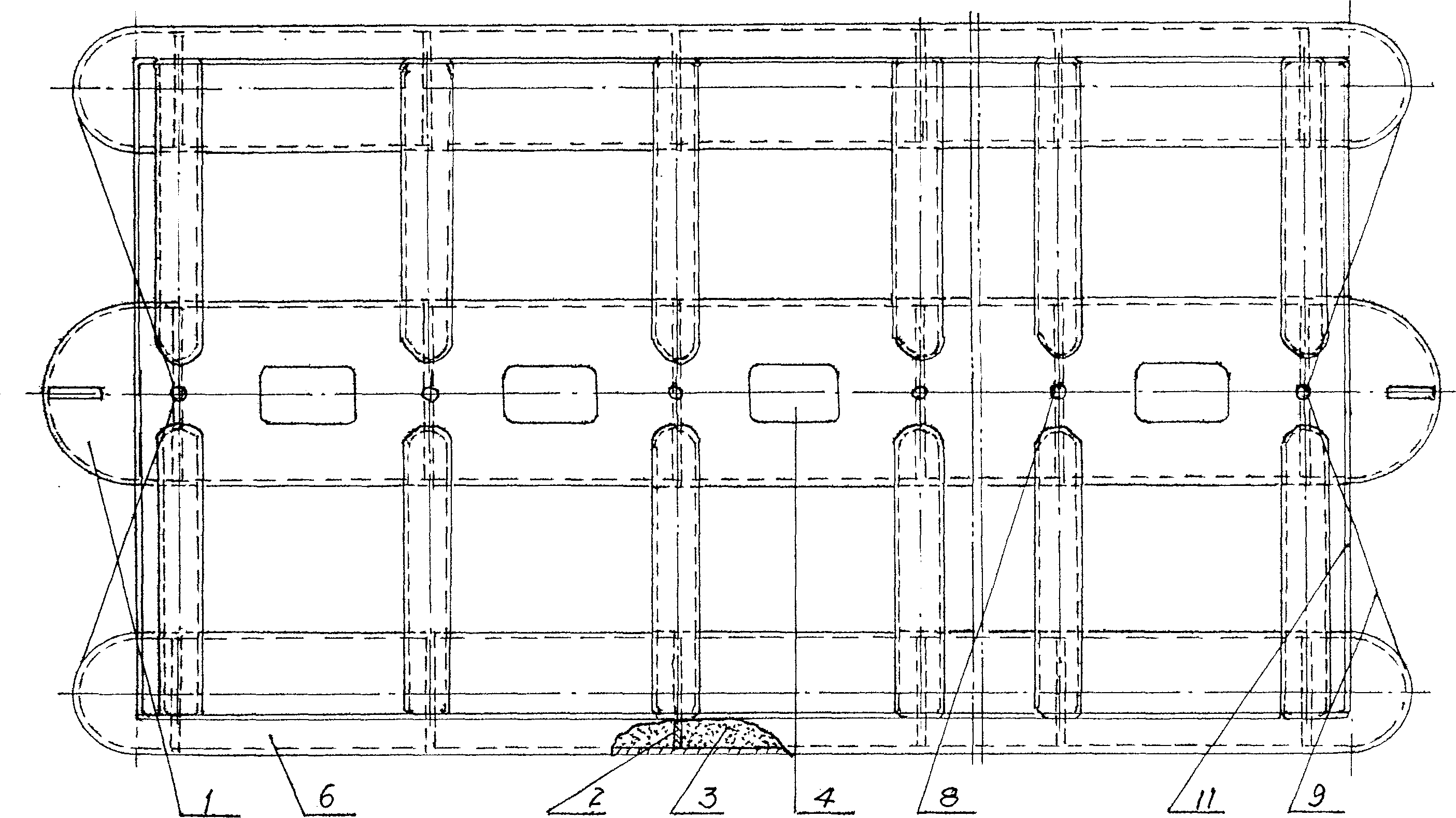

Two-body target boat of float structure

InactiveCN1421671AImprove impact resistanceWon't lose stabilityMovable targetsMarine engineeringBuoyancy

The two-body target boat with float structure has two parallel tubular hulls with round head, which are separated with partition boards into separate buoyancy compartments filled with light foamed material; deck to connect two hulls, which consists of parallel connecting pipes perpendicular to hulls and filled with light foamed material, inclined pull rods between connecting pipes, and deck surface of metal plate or wooden board; mast; pull rope and guardrails. The target boat has powerful hit resistance.

Owner:刘红静

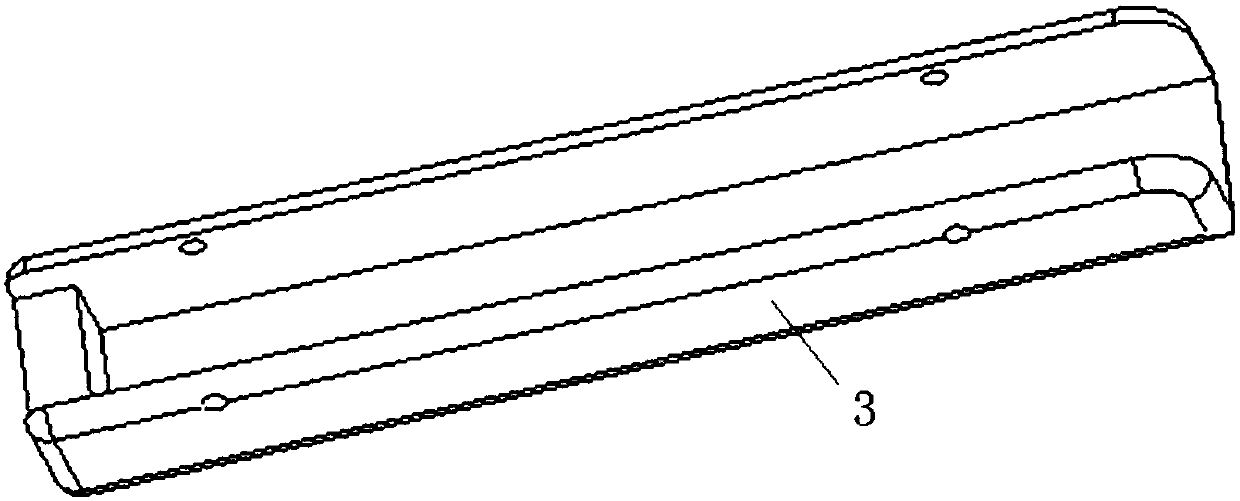

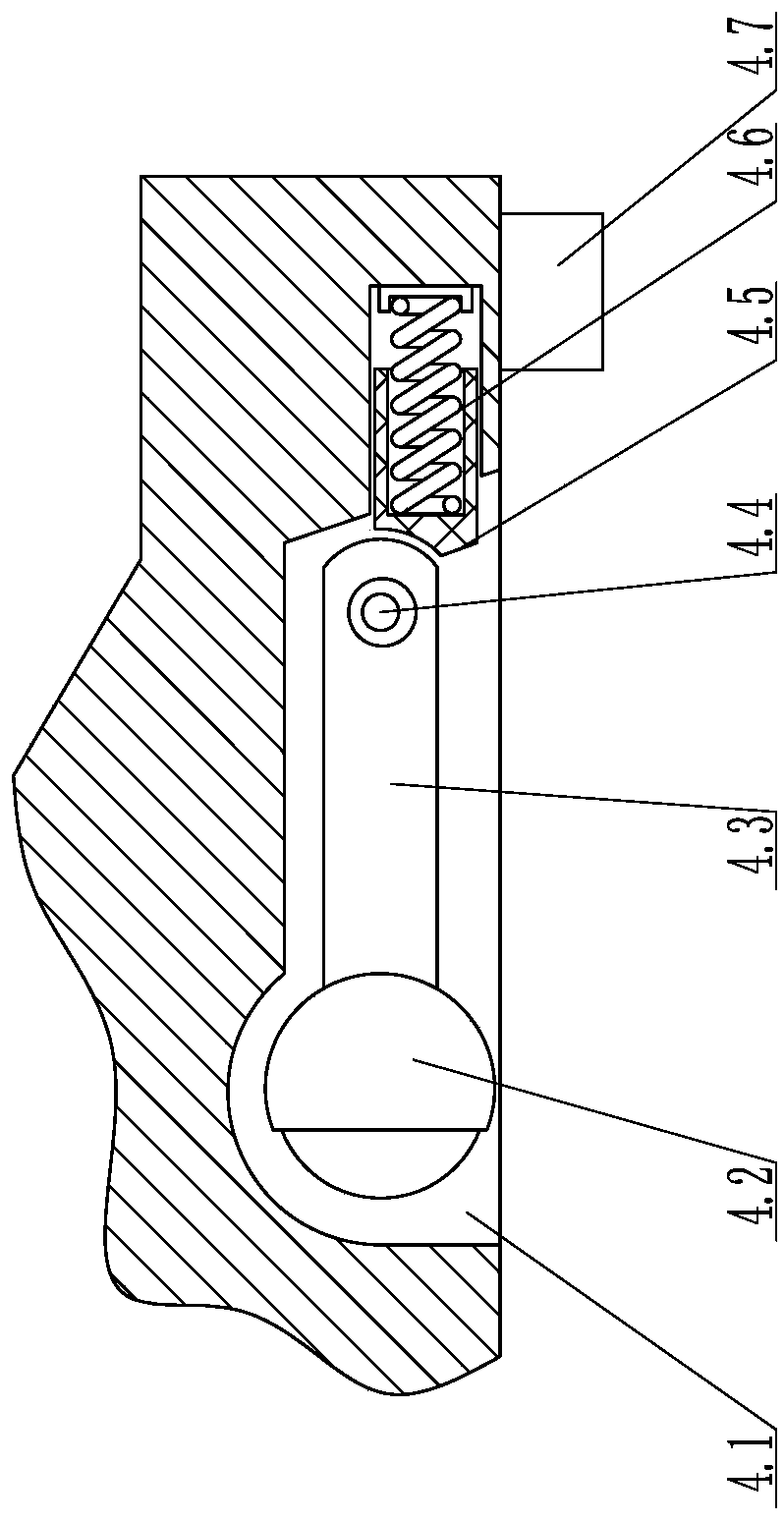

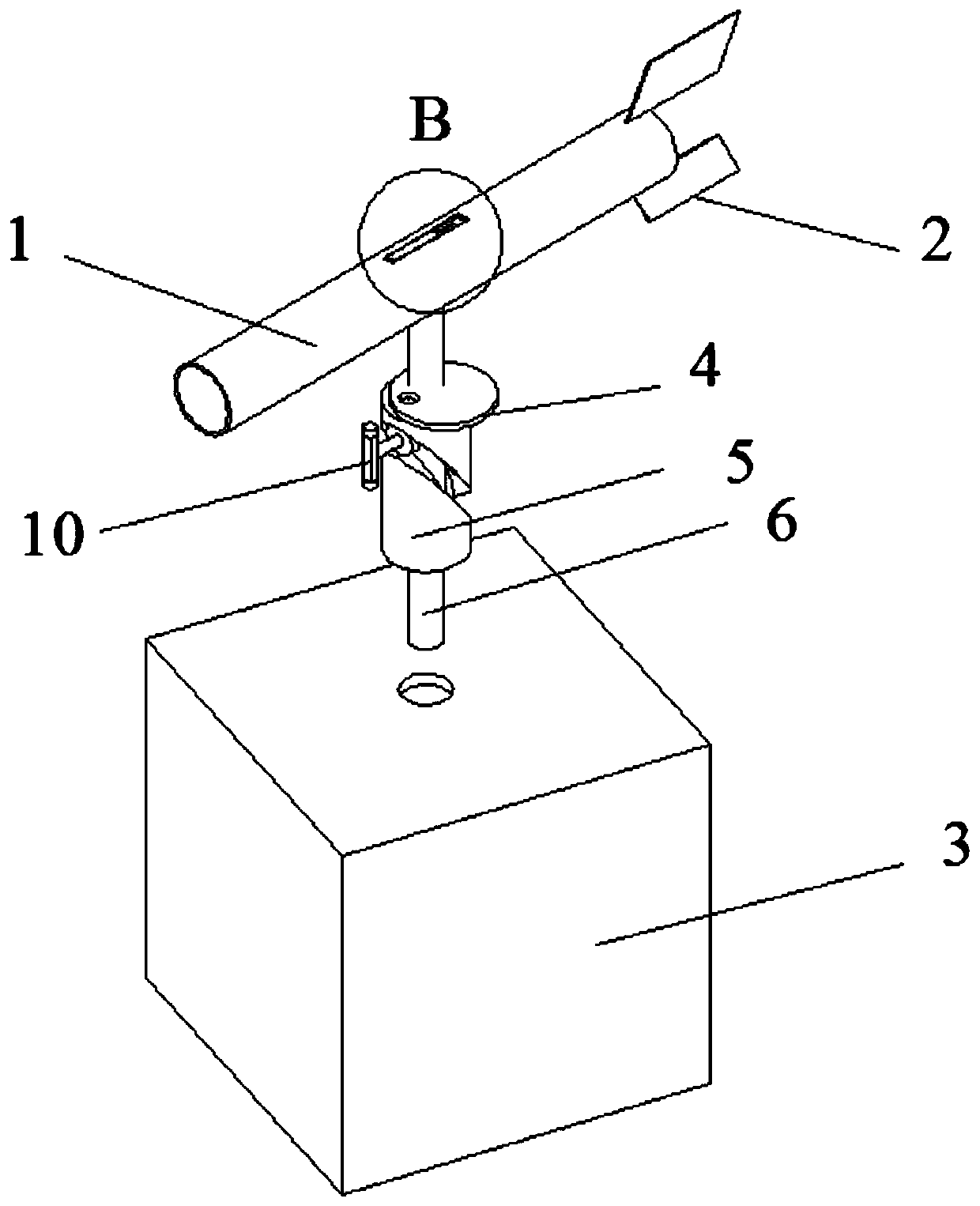

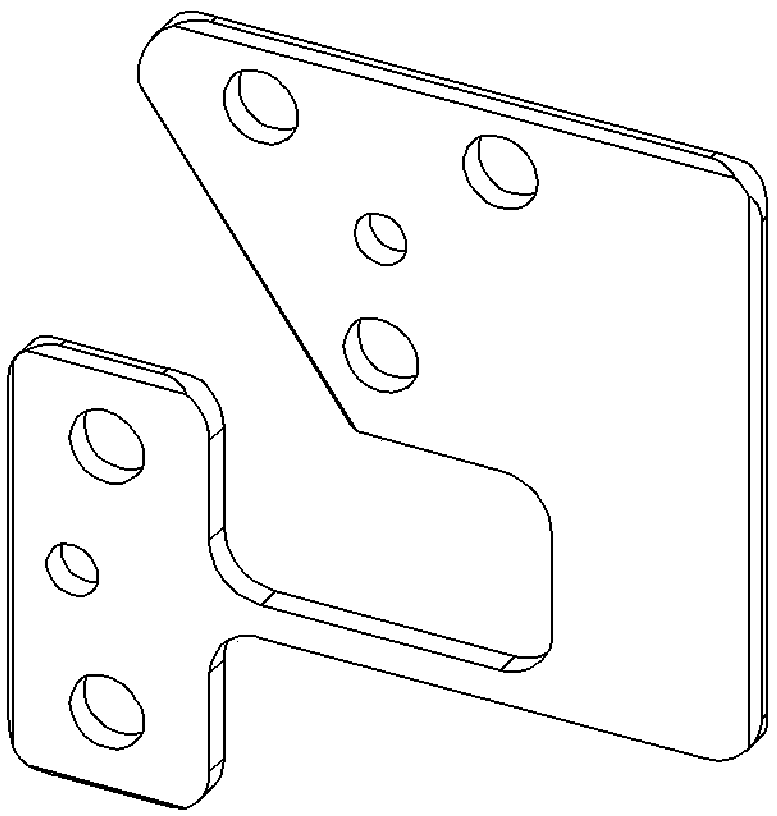

Split washer mounting tool

The invention relates to a split washer mounting tool which comprises a slideway, a push rod, a push rod cover, an auxiliary rod, a handle, a swing rod, a pin, a magnet and a resetting spring. A U-shaped mounting groove for positioning a shaft part is formed in the front end of the slideway, the magnet is mounted on the slideway positioned in rear of the U-shaped mounting groove, and a connectingplate is integrally arranged at the rear end of the slideway; the push rod is slidably arranged on the slideway, a retaining block is arranged at the rear end of the push rod, the push rod cover is mounted on the slideway in a fastened manner, and a notch for the front end of the push rod to penetrate out is arranged at the front end of the push rod cover; the auxiliary rod is fixedly connected with the retaining block, the pin is mounted at the rear end of the auxiliary rod, the handle is fixedly connected with the connecting plate, the swing rod is positioned in front of the handle, the middle of the swing rod is rotatably connected with the connecting plate while the upper end of the same is provided with a kidney-shaped hole, and the pin is positioned in the kidney-shaped hole; the resetting spring is mounted in a cavity formed by the push rod cover and the slideway, and one end of the resetting spring is abutted against the front end of the push rod cover while the other end of the same is abutted against the retaining block.

Owner:XUZHOU NORMAL UNIVERSITY

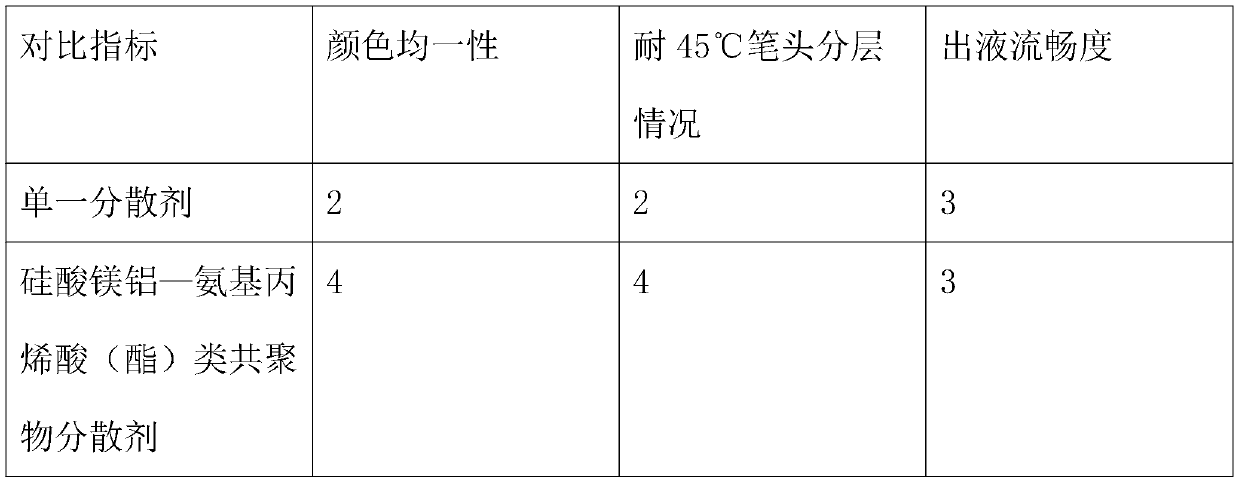

Cosmetic grade water-based pigment composite dispersant and production method thereof and liquid pen

InactiveCN110302097APrevent hardeningGood moisture controlCosmetic preparationsToilet preparationsWater basedAluminum silicate

The invention discloses a cosmetic grade water-based pigment composite dispersant and a production method thereof and a liquid pen using the composite dispersant. The cosmetic grade water-based pigment composite dispersant is prepared from magnesium aluminum silicate, deionized water and an amino acrylic acid (ester) copolymers. The cosmetic grade water-based pigment composite dispersant is non-toxic and non-irritating, has good economic benefits, can be used as an excellent suspending agent, can improve the effectiveness of the amino acrylic acid (ester) copolymers, can be used as a modifierand thickener for viscosity to obtain an excellent suspension effect in a lower viscosity range, and has a wide range of PH range stability.

Owner:宁波爱诗化妆品有限公司

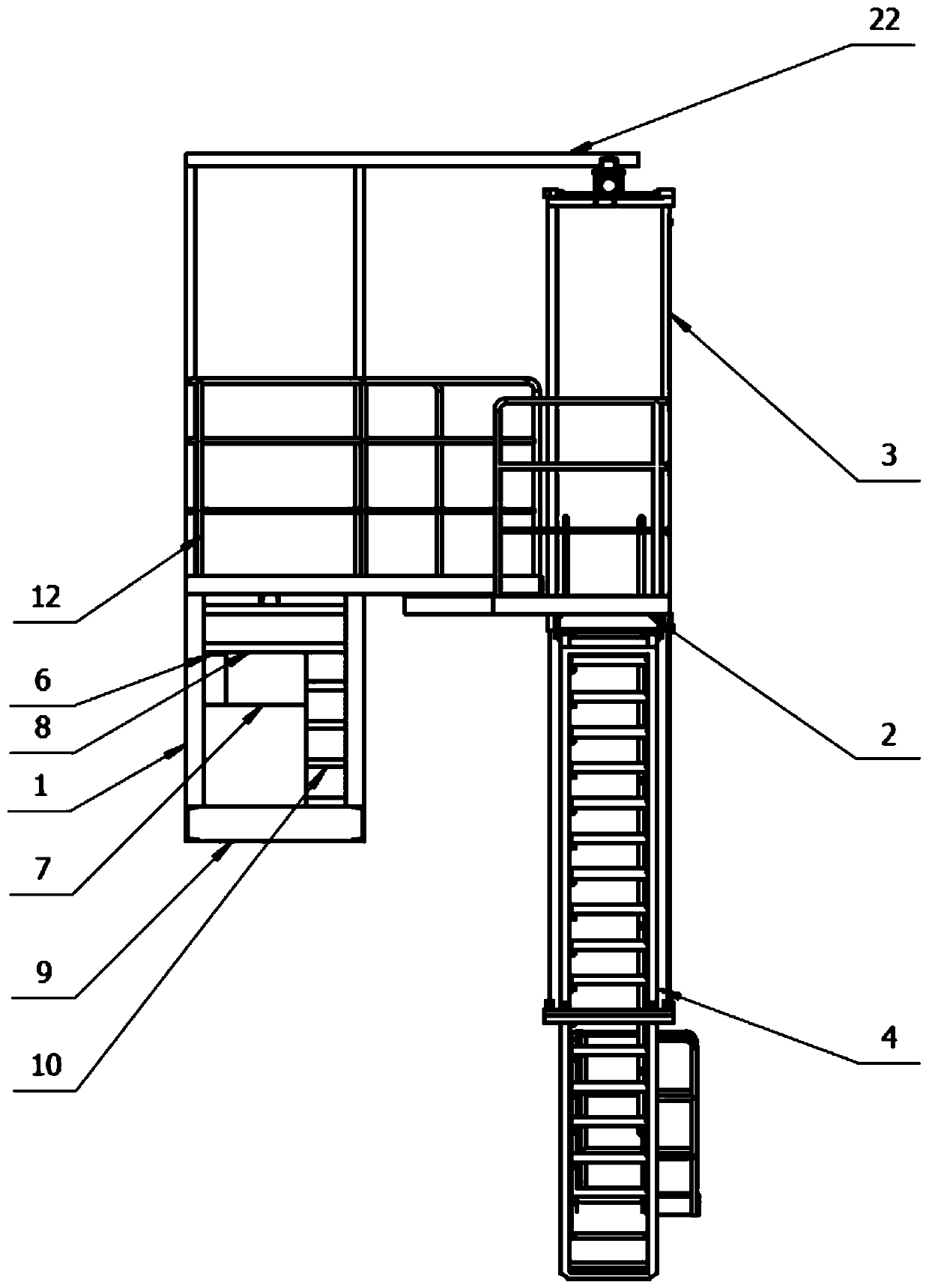

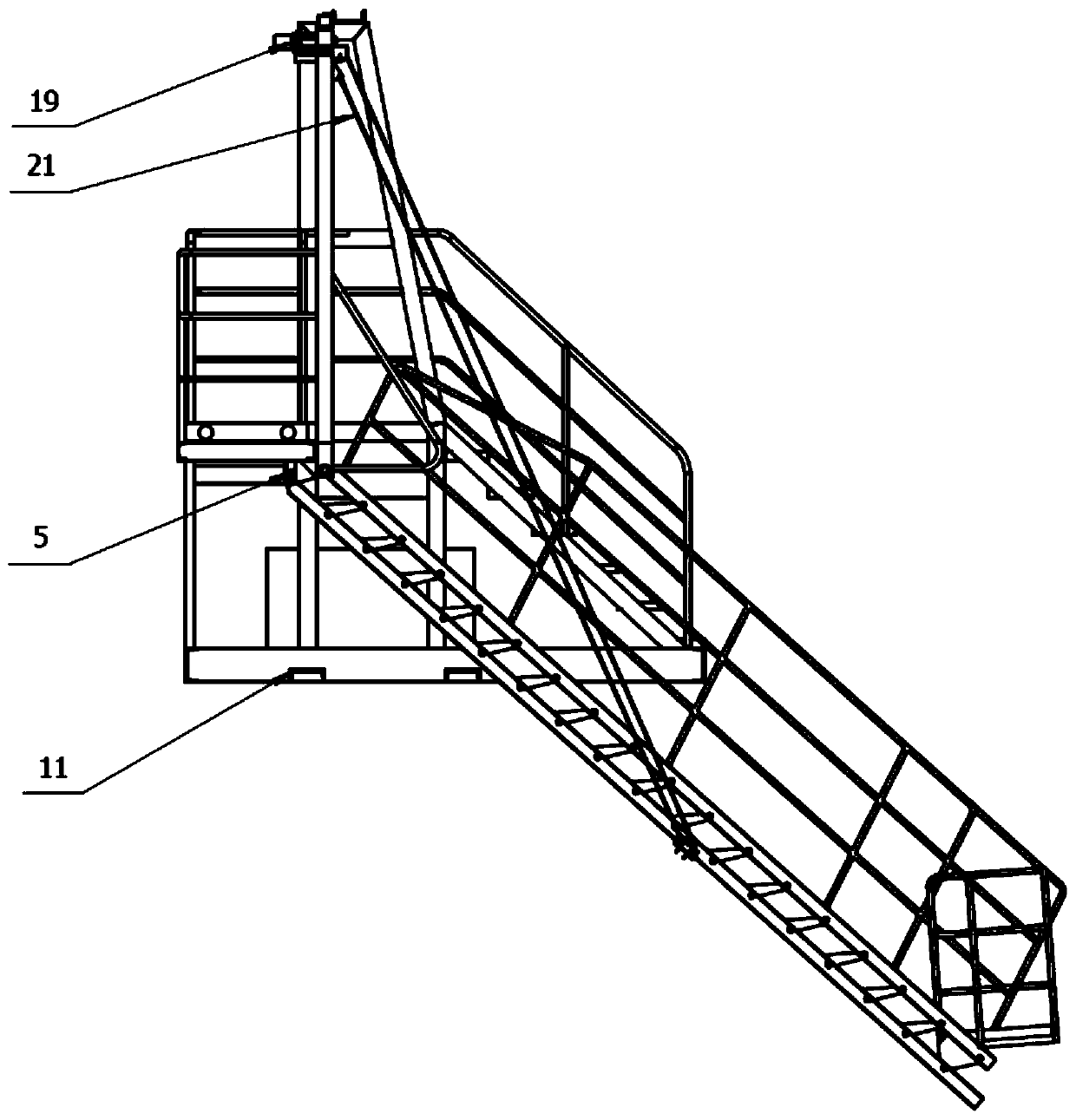

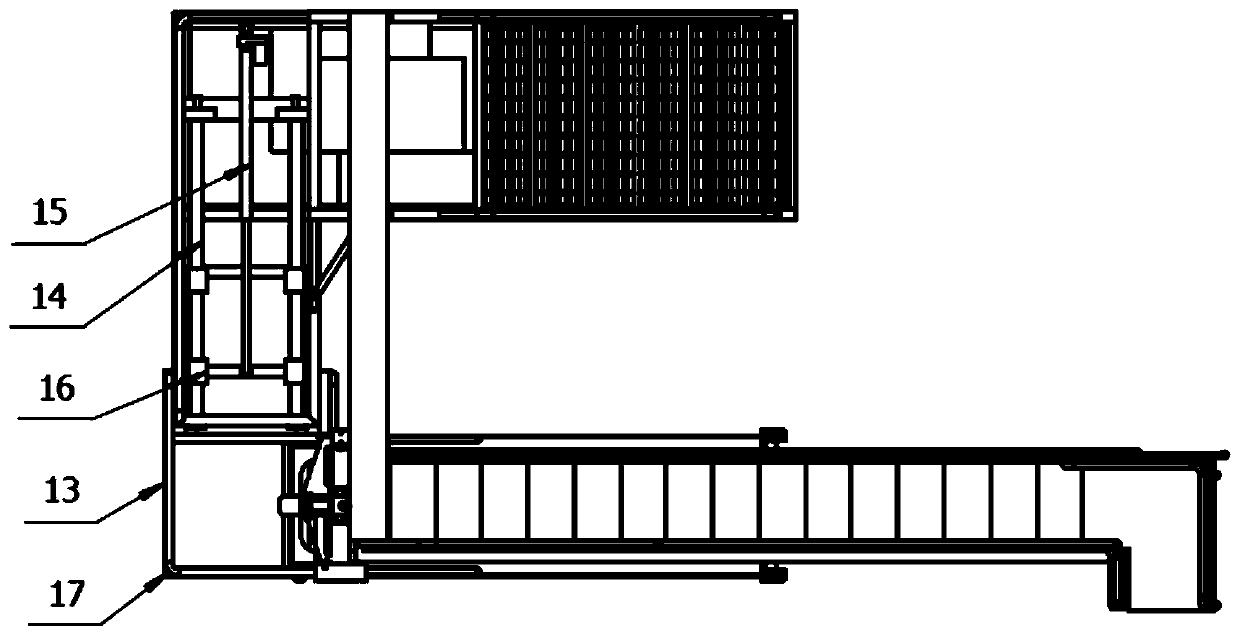

Barge boarding device

PendingCN111409778AMeet the use requirementsCompact structureCargo handling apparatusPassenger handling apparatusStructural engineeringLightering

The invention provides a barge boarding device. The barge boarding device comprises a first boarding assembly, a translation assembly, a folding and unfolding assembly, a second boarding assembly anda battery assembly, wherein the first boarding assembly is connected with a wharf and the translation assembly, the translation assembly is connected with the first boarding assembly and the second boarding assembly and used for moving the second boarding assembly in the horizontal direction, the folding and unfolding assembly is integrated with the translation assembly and used for ascending anddescending the second boarding assembly in the vertical direction, the second boarding assembly is connected with a ship and the translation assembly, and the battery assembly is electrically connected with the translation assembly and the folding and unfolding assembly and used for supplying power. The barge boarding device is advantaged in that the first boarding assembly, the translation assembly, the folding and unfolding assembly, the second boarding assembly and the battery assembly are orderly combined together, so the structure is compact, and the integration degree is high, the translation assembly ensures that the second boarding assembly is close to the ship in the horizontal direction, the folding and unfolding assembly and the translation assembly are integrated to ensure thatthe second boarding assembly is close to the ship in the vertical direction, and use requirements of small and medium-sized ships are particularly met.

Owner:SHEKOU CONTAINER TERMINALS +1

Composite lining suitable for surrounding rock after-deformation

InactiveCN100425803CWon't lose stabilityWon't breakUnderground chambersTunnel liningSoft layerEngineering support

The invention relates to a complex lining adaptive to the great deformation of adjacent rock, relating to underground engineering supporting structure. To resolve the problem that existing linings is no suitable for the evening converge and fracture deformation, the invention discloses a complex lining which includes inner layer and outer layer, the inner layer is concrete layer of thickness 30 to 200 cm and is a rigid layer, the outer layer is a filling layer filled with dirt, rock, sand, and water with a thickness of 30 -150 cm, and is a soft layer. The complex lining adapts the fracture deformation with its deformable outer layer while providing proper support to the adjacent rock protecting inner layer and supporting adjacent rock to stabilize the rock.

Owner:NANJING HYDRAULIC RES INST THE MINISTRY OF WATER RESOURCES THE MINIST

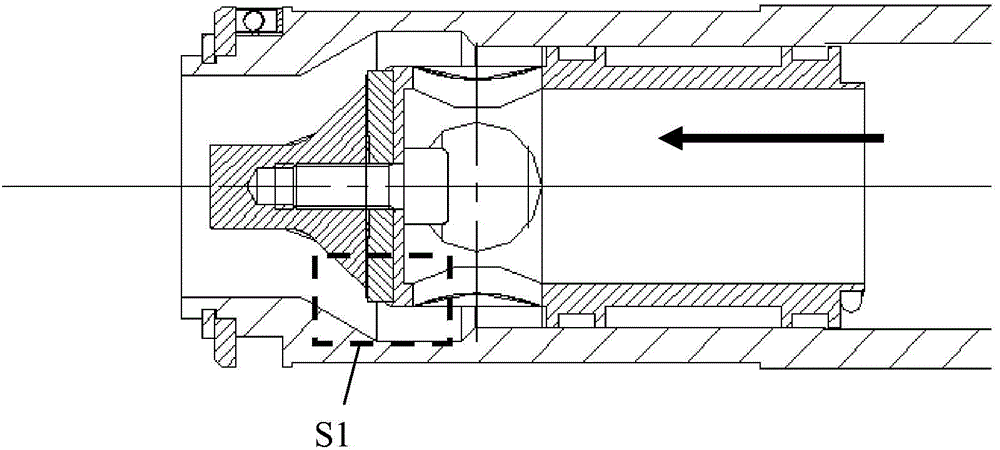

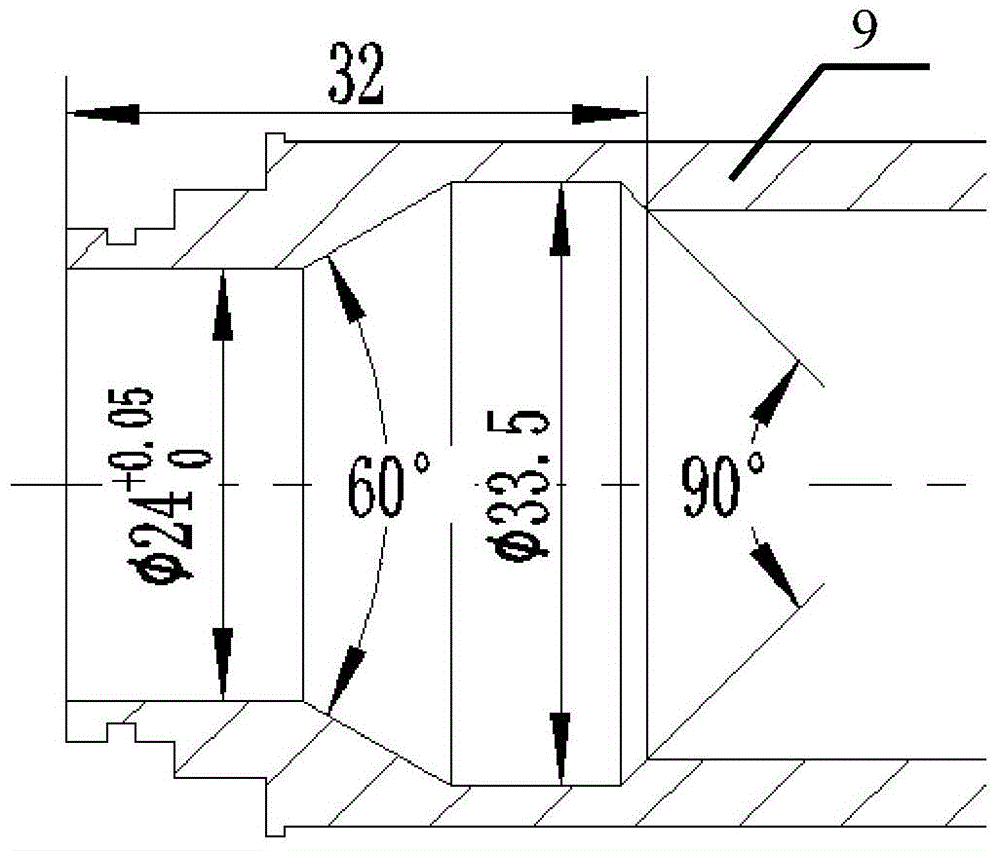

Sealing structure based on non-return stop valve

InactiveCN103953763ATo achieve the purpose of sealingSolve seal failureCheck valvesLift valveStructure basedGlobe valve

The invention discloses a sealing structure based on a non-return stop valve. The sealing structure comprises a stop valve clack, a stop valve sealing ring, a fastening bolt, a non-return valve rod and a cavity, wherein the stop valve clack is in fit and fixed connection with the stop valve sealing ring, and a fixing groove used for fixing the fastening bolt is formed in a direction facing to the cavity; a through hole for arranging the fastening bolt in a penetrating manner is formed in the center position of the stop valve sealing ring, and is formed between the stop valve clack and the non-return valve rod in a close fit manner; the non-return valve rod is in tight fit with the stop valve sealing ring, and a fixing hole for fixing the fastening bolt is formed in the non-return valve rod; the fastening bolt is used for fixing the non-return valve rod, the stop valve sealing ring and the stop valve clack in a tight fit manner; a tapered cavity structure shrinking towards a port direction is formed in the port of the cavity. The sealing structure provided by the invention solves the problem of sealing failure due to structure unbalance of the non-return valve of a low-temperature medium sealing structure after repeated filling and sealing.

Owner:BEIJING XINGSHI HUARONG TECH DEV

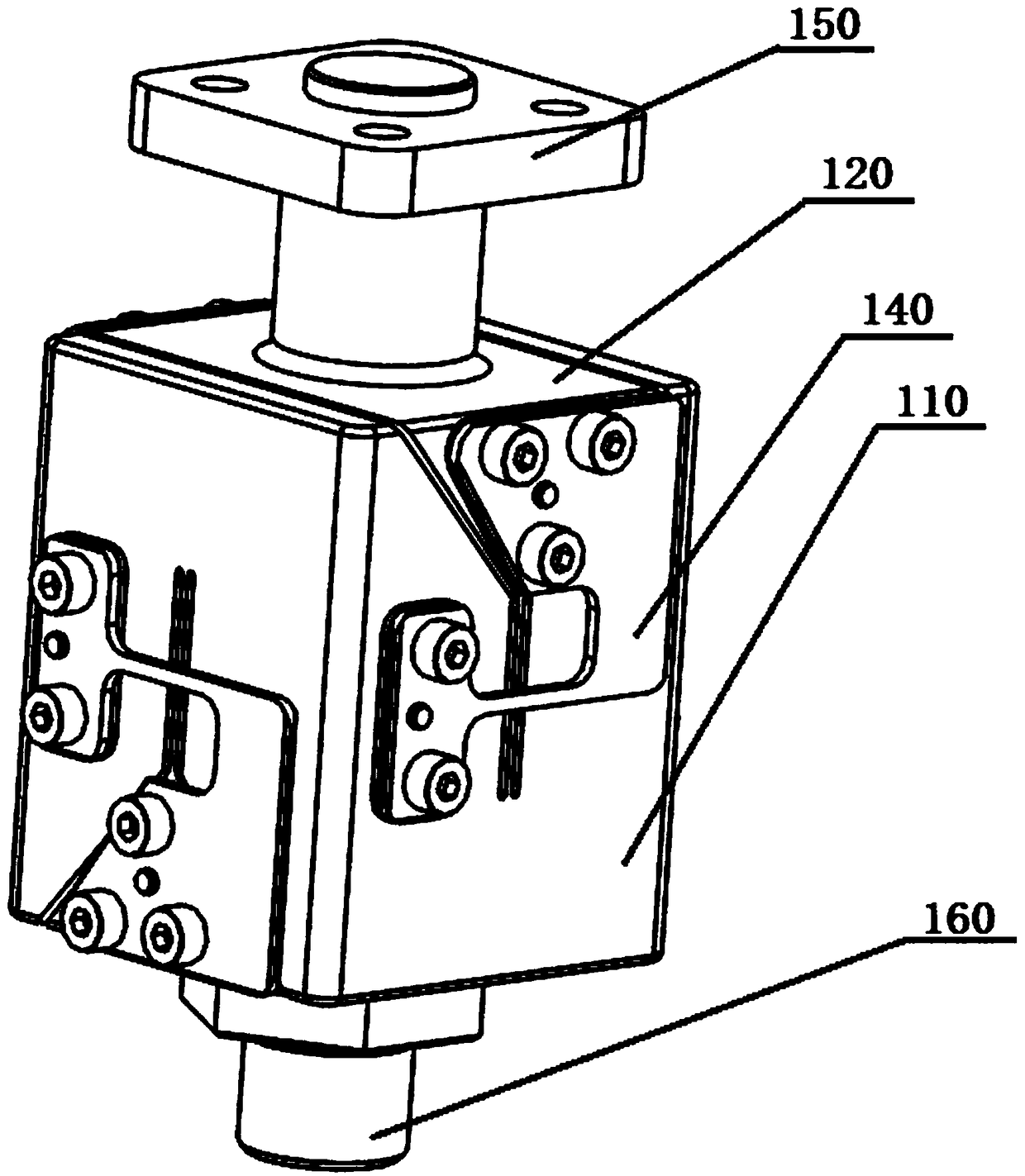

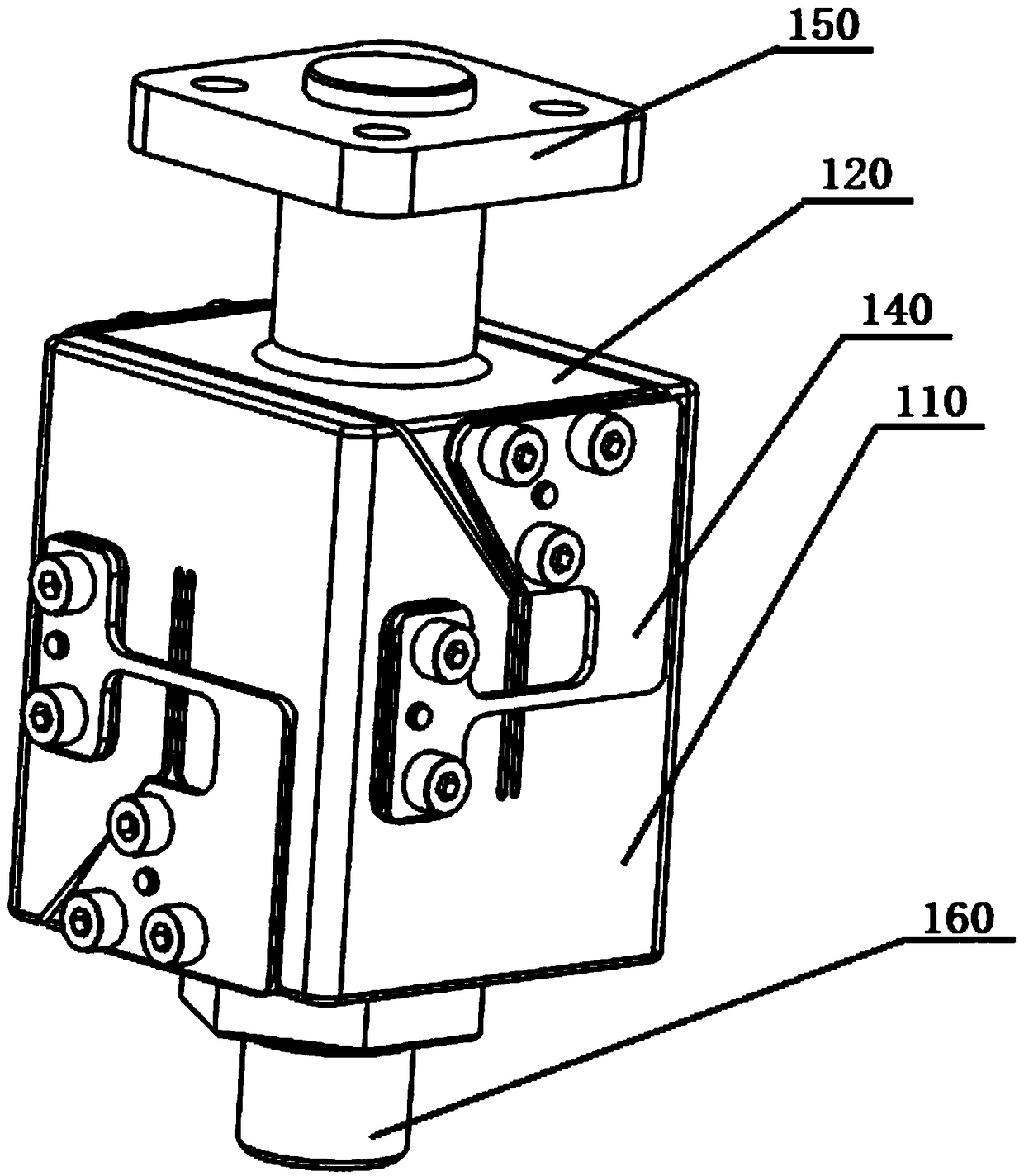

Universal flexible force-measuring component

PendingCN109163836ARealize universal movementRealize the measurement of vector forceApparatus for force/torque/work measurementHydraulic cylinderEngineering

The invention provides a universal flexible force-measuring component. The universal flexible force-measuring component comprises a first connecting plate, a hydraulic cylinder, an adapter, a first universal flexible member, a force-measuring sensor and a second universal flexible member which are sequentially connected with each other. According to the universal flexible force-measuring componentprovided by the invention, the two universal flexible members are arranged, so that the universal movement of the force-measuring component is realized, thus the measurement of the vector force of asix-component test bed is realized, the implementation accuracy is improved, and the structure is simple.

Owner:BEIJING AEROSPACE SANFA HIGH TECH +1

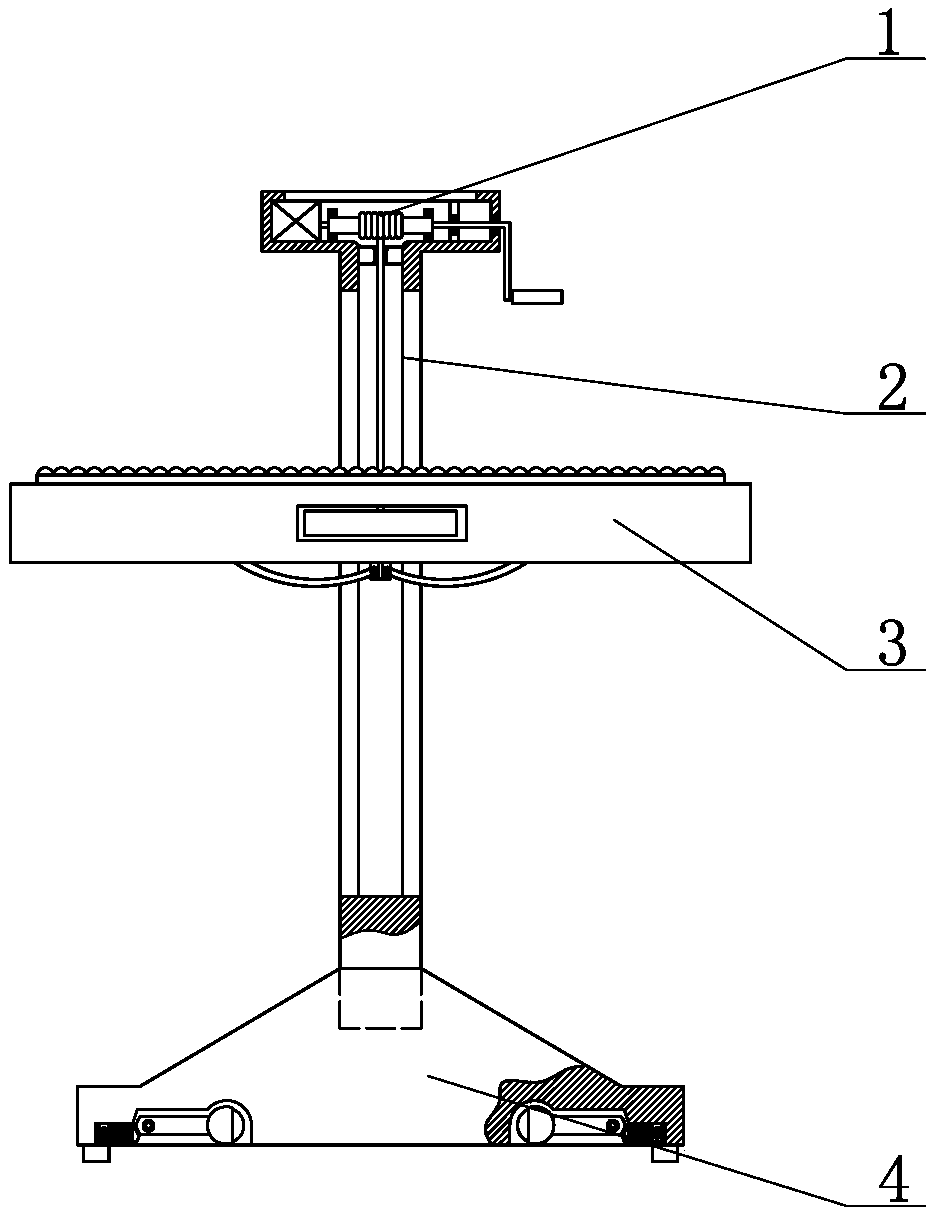

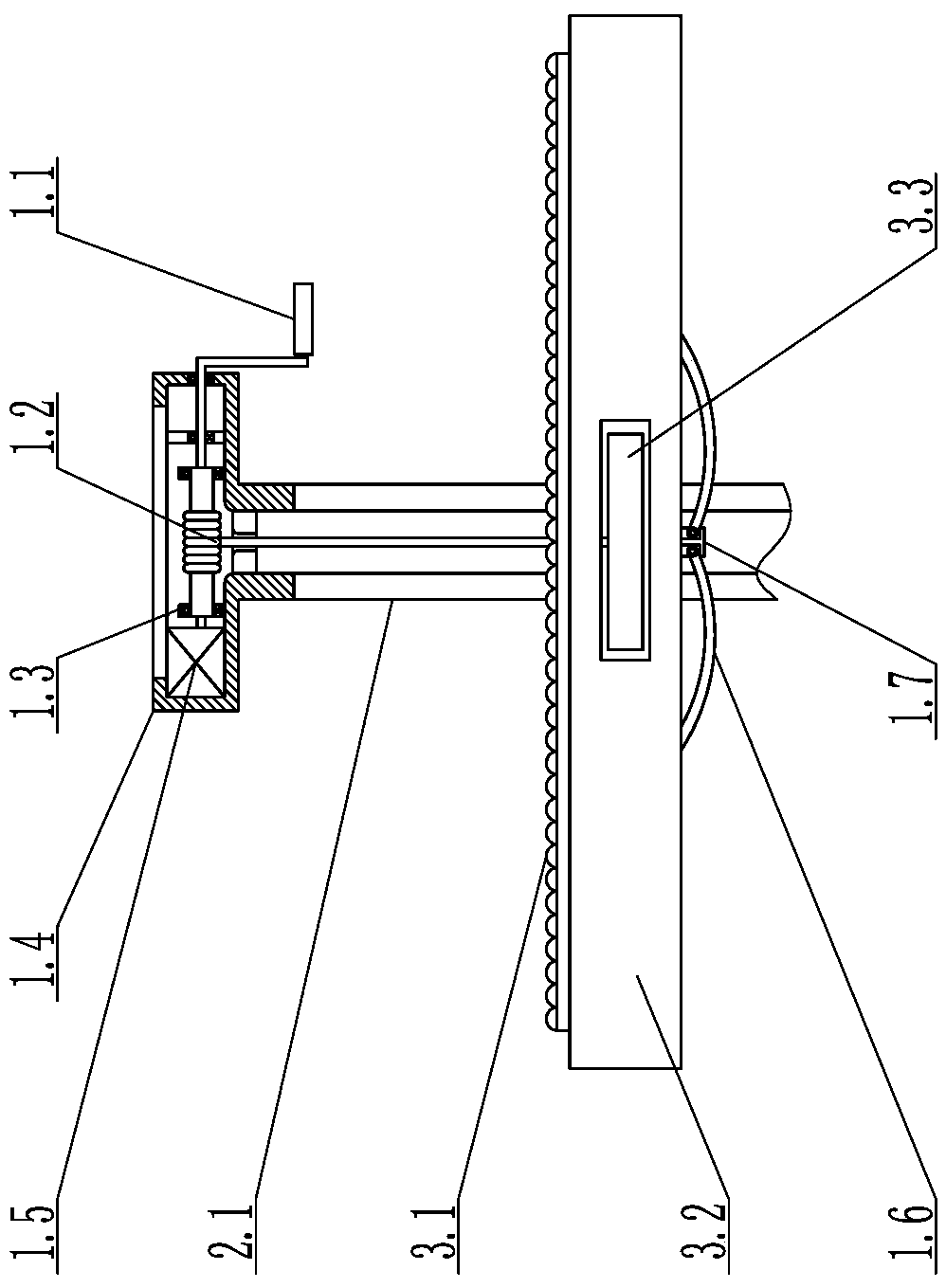

Display moving display platform for teaching

InactiveCN110686151AEasy to fixDoes not affect homeworkNon-rotating vibration suppressionStands/trestlesSoftware engineeringDisplay device

The invention discloses a display moving display platform for teaching, and belongs to the technical field of functional teaching aid equipment. The display platform is characterized by comprising a functional base, a stand column, a lifting platform and a lifting control device, wherein the lower end of the stand column is fixed on the functional base in an inserted mode, the lifting platform isprovided with a sliding through hole, the lifting platform sleeves the stand column through the sliding through hole, and the lifting control device can drive the lifting platform to move up and downalong the stand column and to hover at a specified position. According to the display platform, a teacher can conveniently fix a computer display on the lifting platform, the teaching content is independently displayed to a corresponding student through the movable functional base without affecting the self-learning operation of other students, and in addition, the display can be fixed through anelastic strapping tape, the display can be firmly arranged in the moving process, and a screen is prevented from being skewed or damaged due to vibration.

Owner:郭祯翔

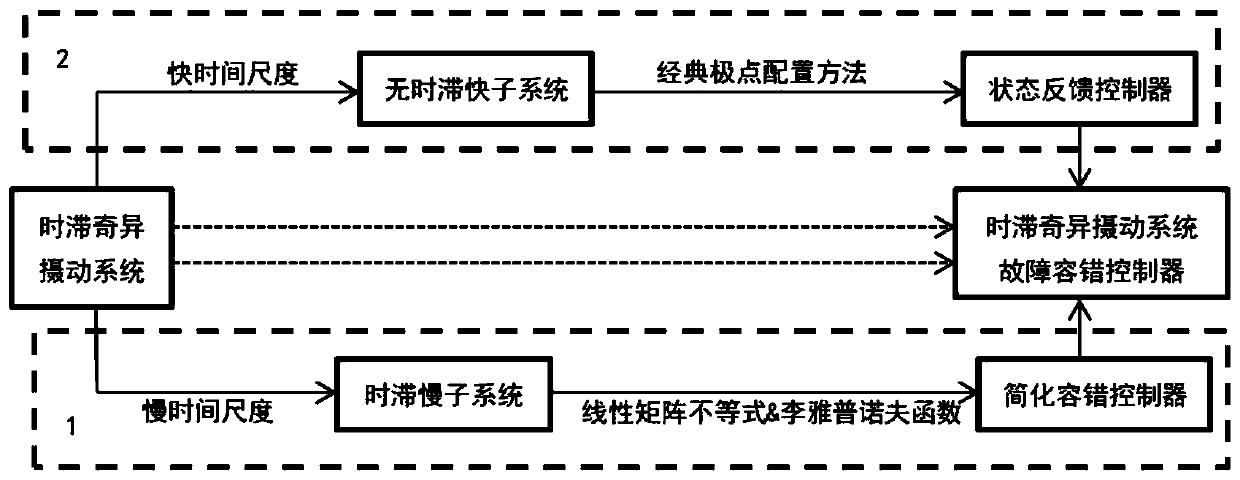

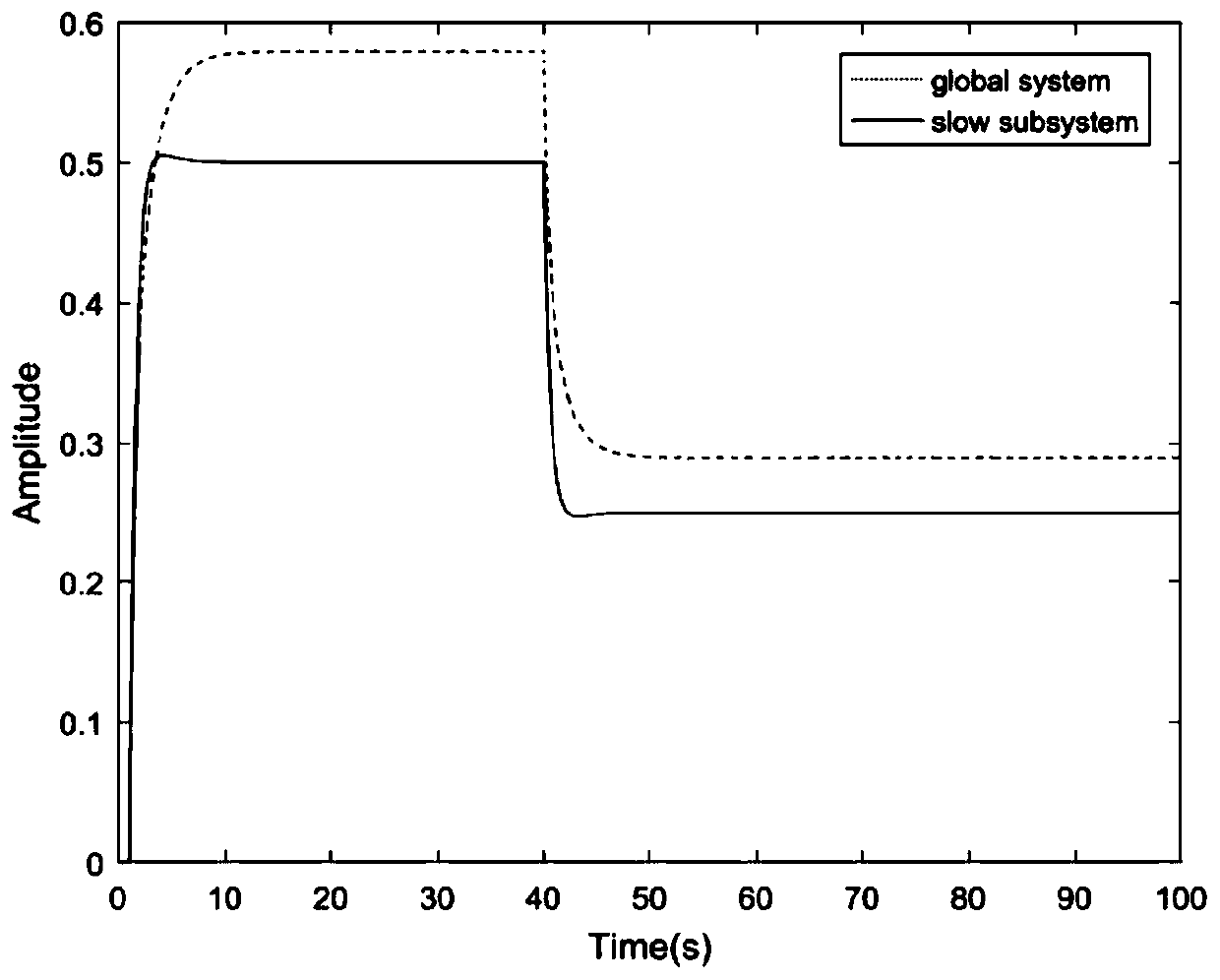

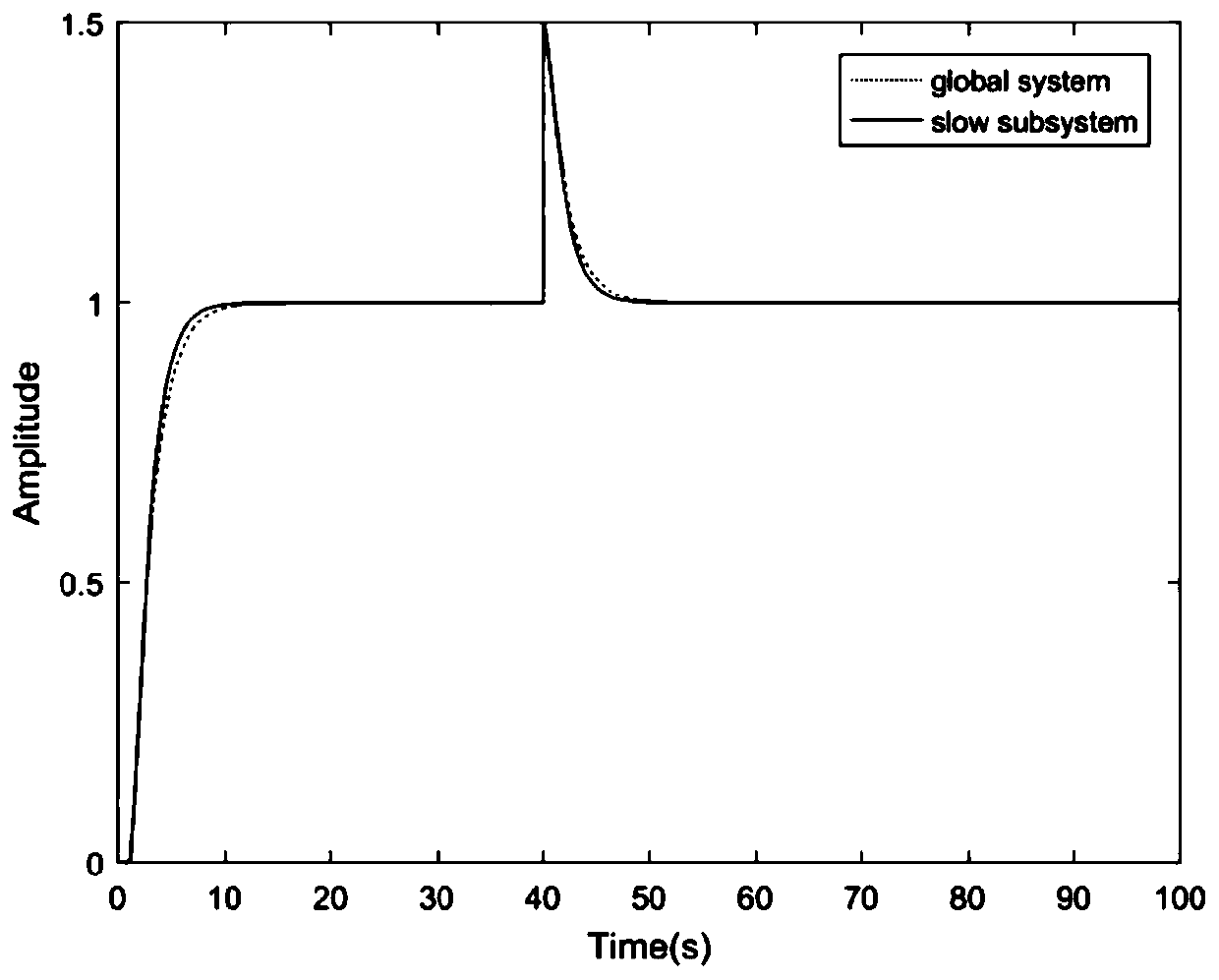

Fault-tolerant control method for singularly perturbed system with time delay

ActiveCN110361973AWon't lose stabilityCompensation errorAdaptive controlTime delaysFeedback controller

The invention discloses a fault-tolerant control method for a singularly perturbed system with time delay. Firstly, a singularly perturbed system with time delay is decomposed into a slow subsystem with time delay and a fast subsystem without time delay under different time scales; secondly, a simplified fault-tolerant controller is designed for the slow subsystem with time delay, and a state feedback controller is designed for the fast subsystem without time delay; and finally, the simplified fault-tolerant controller and the state feedback controller are integrated to get a fault-tolerant controller for the whole singularly perturbed system with time delay. The fault-tolerant control method of the invention can make compensation for a sensor fault in a singularly perturbed system with time delay quickly and effectively.

Owner:NANJING UNIV OF INFORMATION SCI & TECH

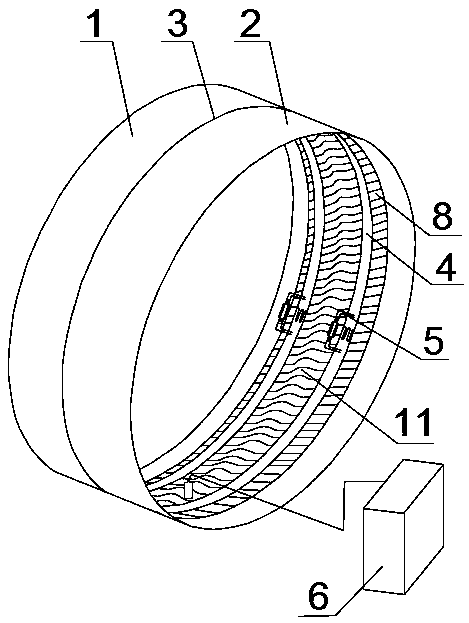

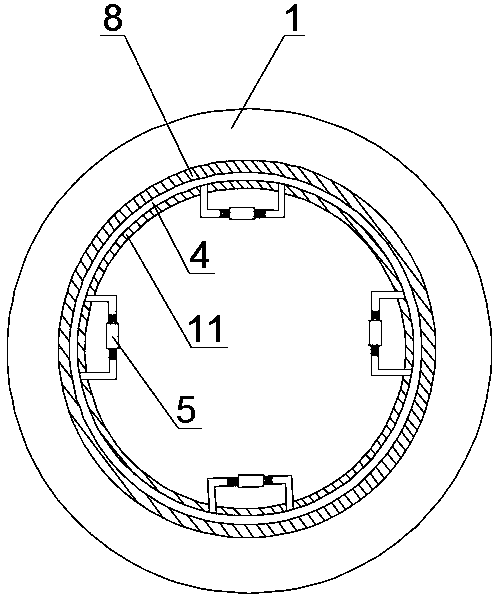

Detecting device for deformation joint leakage of circular tunnels

PendingCN109974949AConfirmed damageIntuitive test resultsMeasurement of fluid loss/gain rateMaterial resourcesEngineering

The invention discloses a detecting device for deformation joint leakage of circular tunnels. The device is detachably arranged at an expansion joint provided with a water stop piece in an embedded manner and located between two circular tunnels, and the detecting device comprises an annular rubber band, an air pressure detecting device and two sets of annular tooth-type connecting steel plates, wherein reverse screw devices are fixed at several joints of each set of tooth-type connecting steel plates, the tooth-type connecting steel plates are pushed by the reverse screw devices to move inthetangential direction at the toothed connecting port such that the tooth-type connecting steel plates can tightly support the annular rubber band onto the inner sides of the circular tunnels, the annular rubber band is provided with an inflation valve, and the air pressure detecting device is connected to the inflation valve through a conduit to detect the air pressure in the sealed space formed by the water stop piece, the expansion joint and the annular rubber band. The detecting device can be used to effectively confirm which section of the expansion joint of the hydraulic tunnels is damaged, and avoid the loss on the human and material resources brought about by large-scale inspection of the hydraulic tunnels.

Owner:美肯沃利工程技术咨询(北京)有限公司

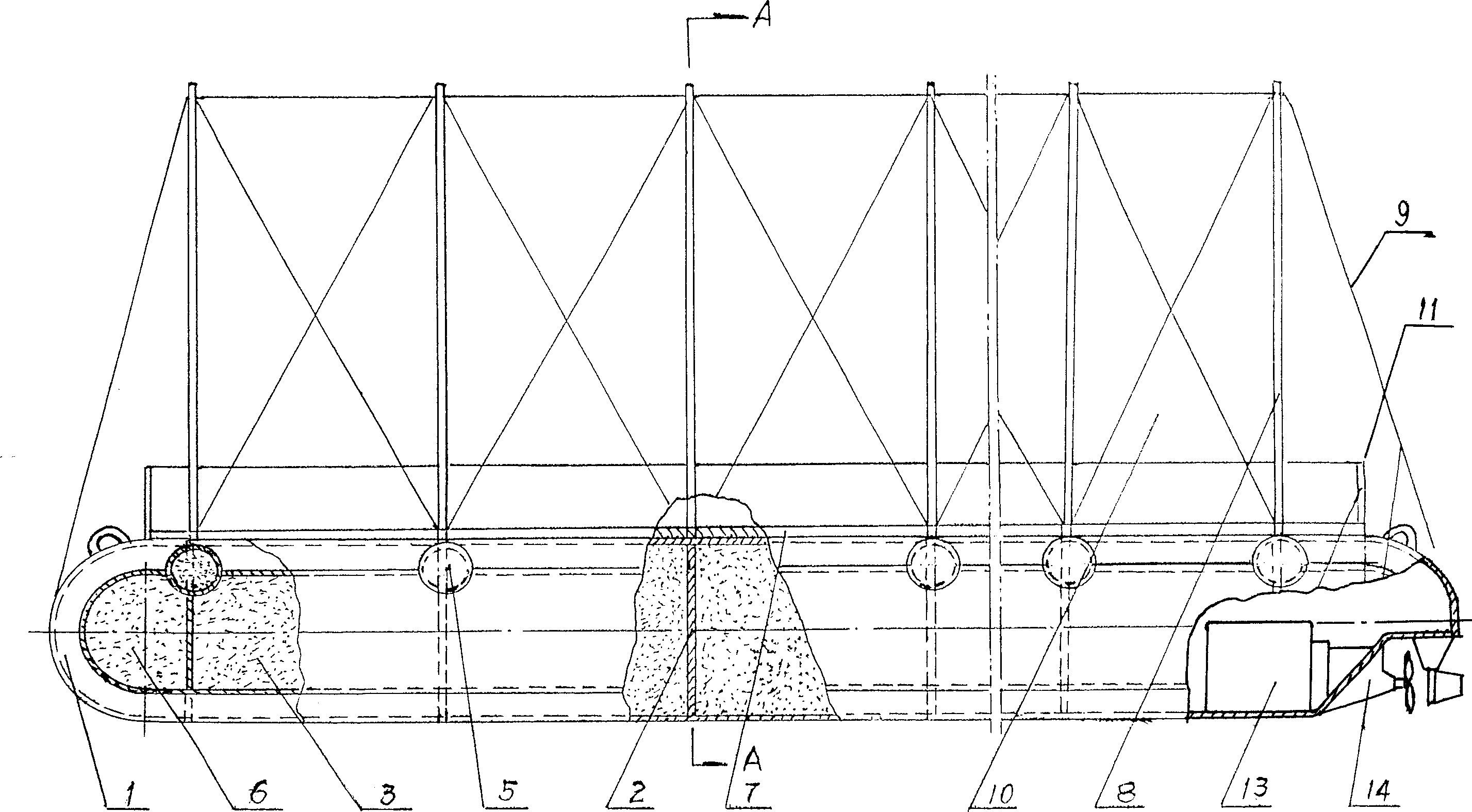

Three-body target boat of float structure

InactiveCN1421672AImprove impact resistanceWon't lose stabilityMovable targetsMarine engineeringBuoyancy

The three-body target boat with float structure has three, one main and two auxiliary, parallel hulls, which are separated with partition boards into separate buoyancy compartments filled with light foamed material; deck to connect three hulls, which consists of parallel connecting pipes perpendicular to hulls and deck surface of metal plate or wooden board; mast; pull rope and guardrails. The target boat has float structure and thus powerful hit resistance.

Owner:刘红静

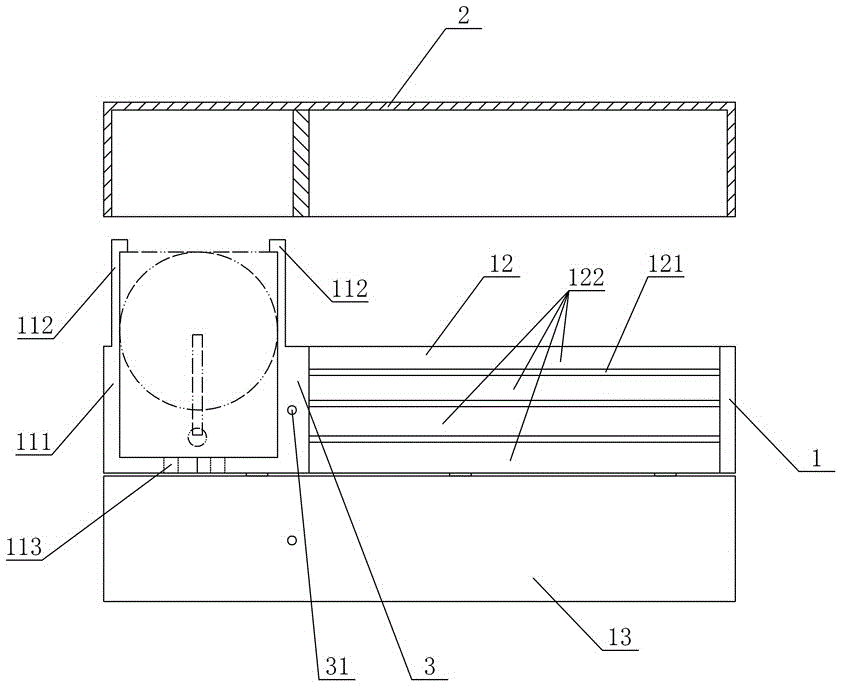

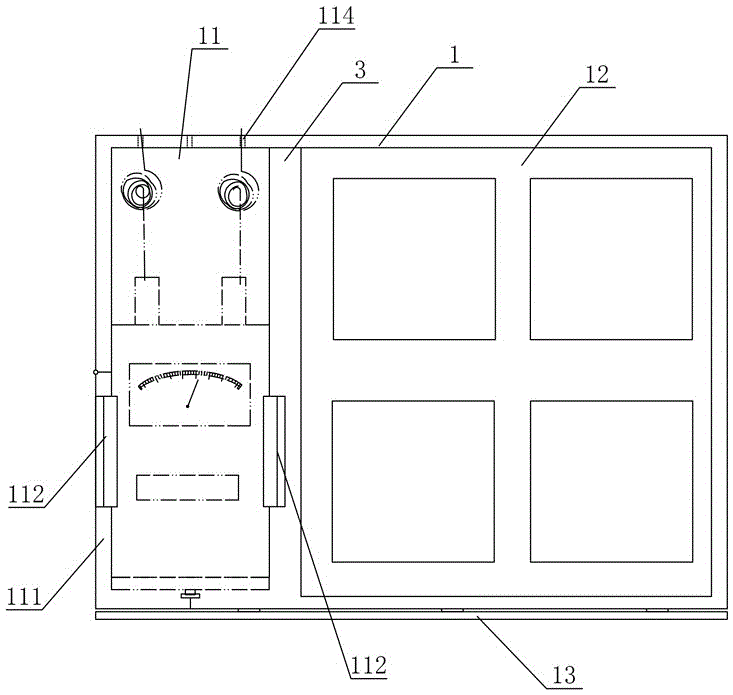

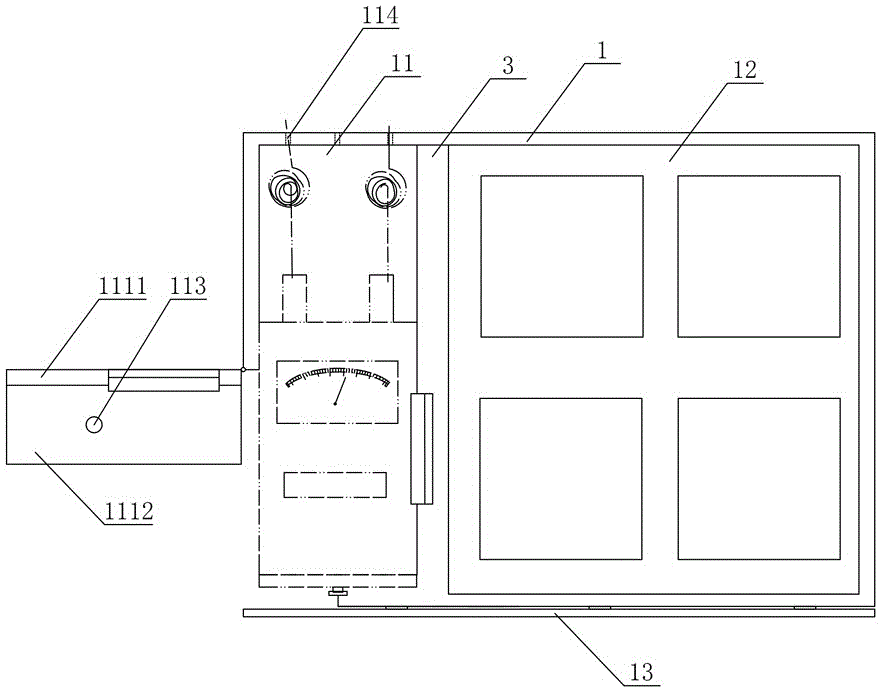

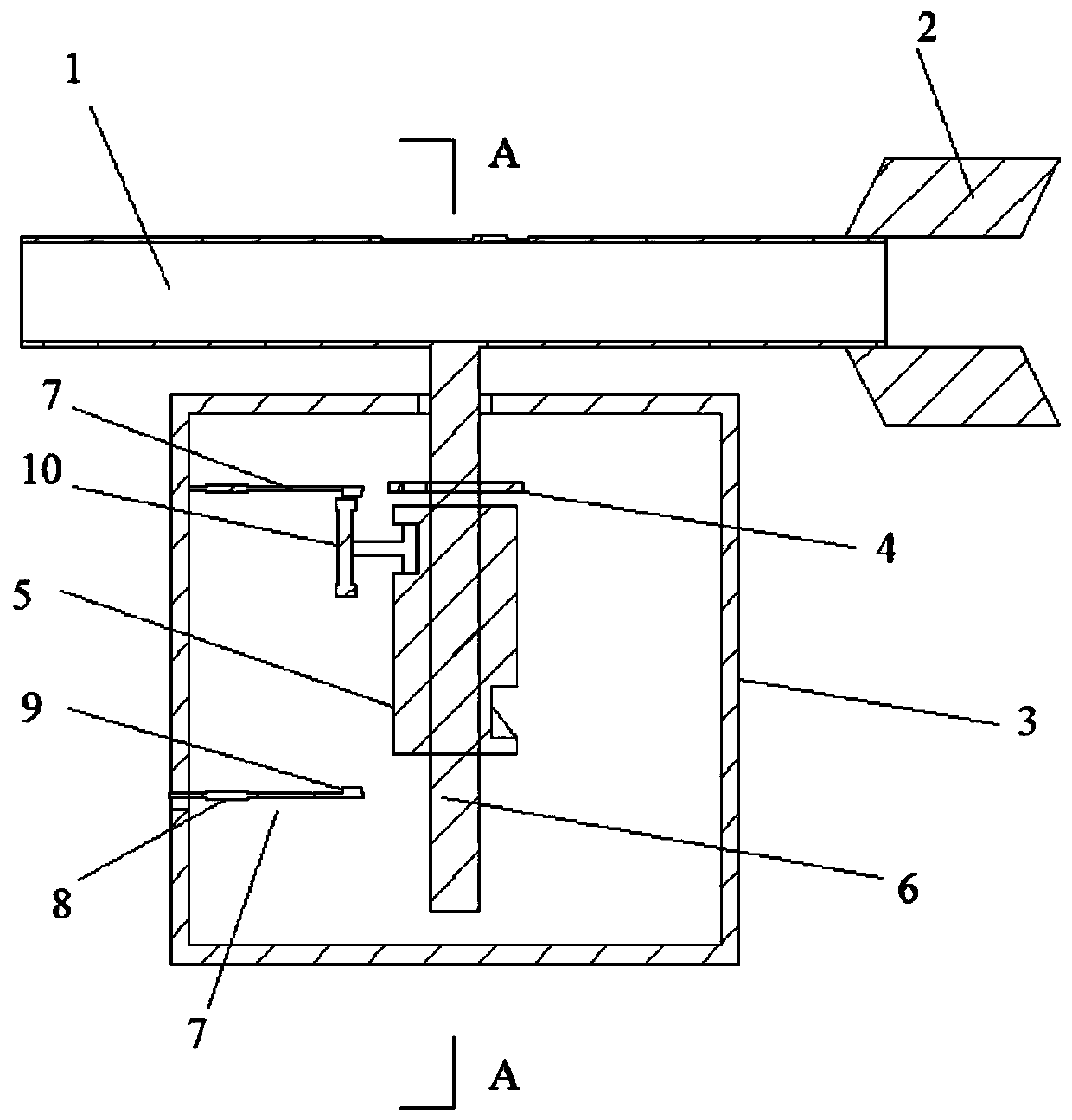

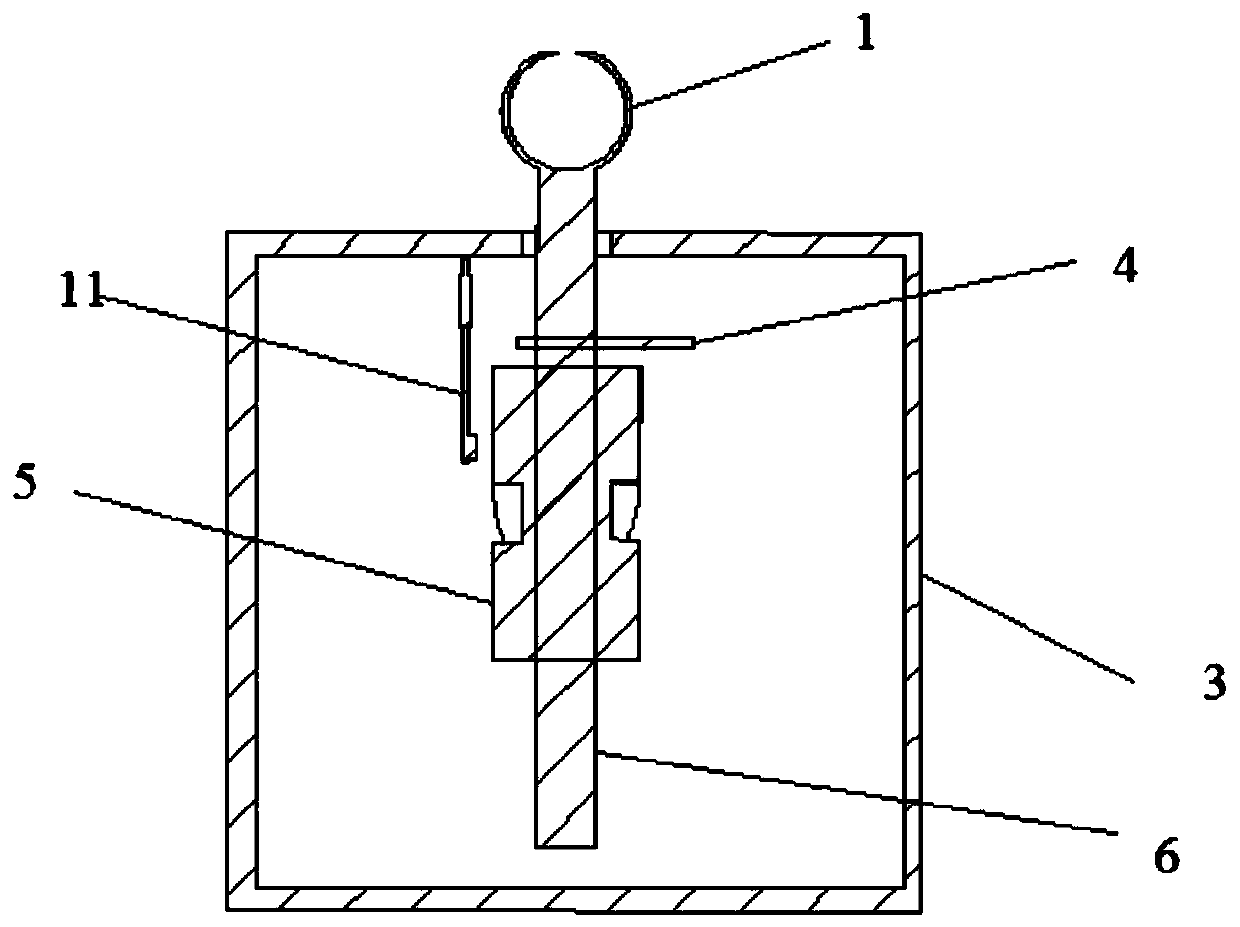

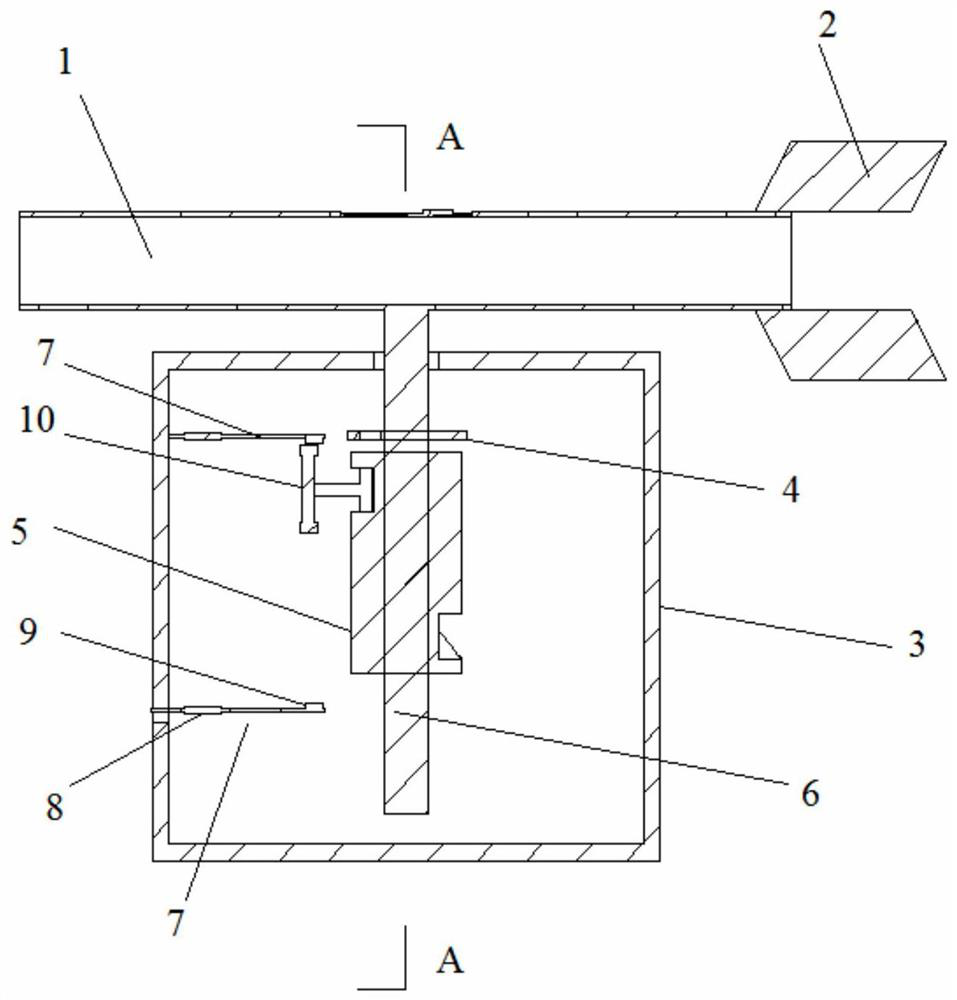

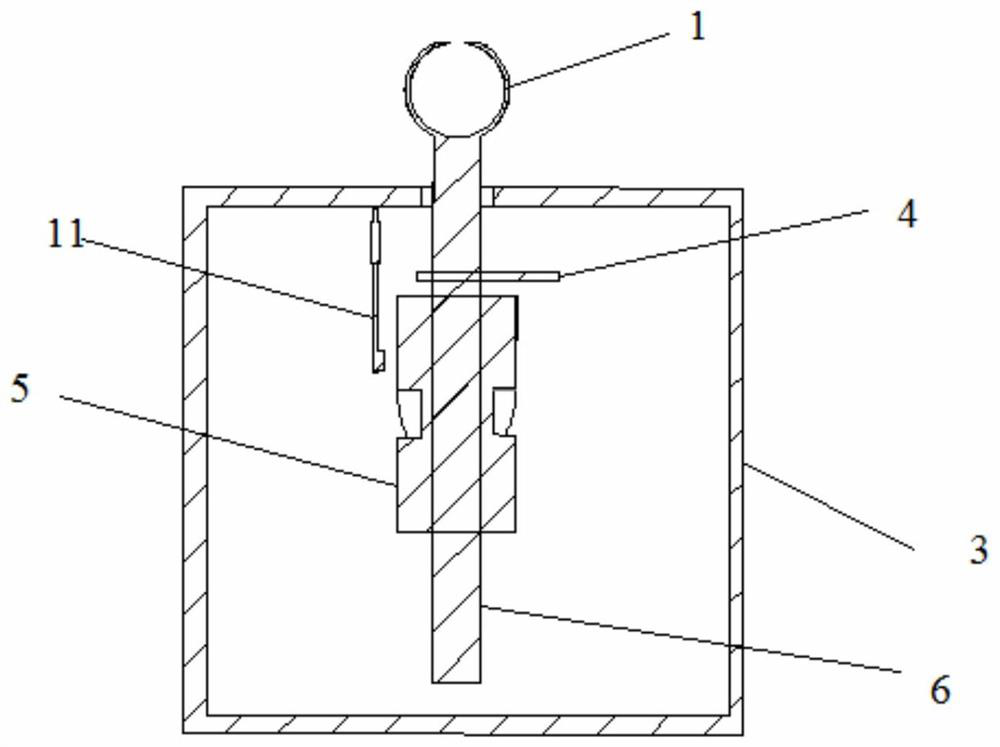

Integrated portable hand-operated megger fixing box

The invention discloses a portable hand-cranked megohmmeter fixed integrated box, which comprises a box body and a box cover arranged on the top of the box body. One side is set as a shaker fixed area, and the other side is set as a tool integration area. The fixed integrated box has the advantages of simple structure, convenient and safe use, and can improve measurement stability and accuracy.

Owner:STATE GRID CORP OF CHINA +2

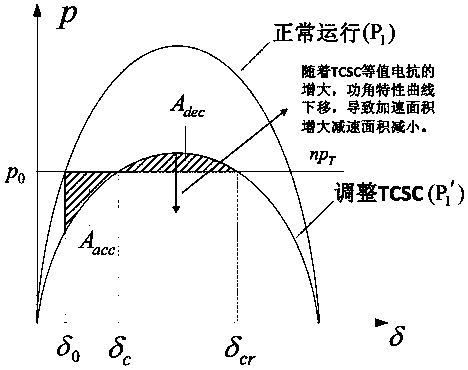

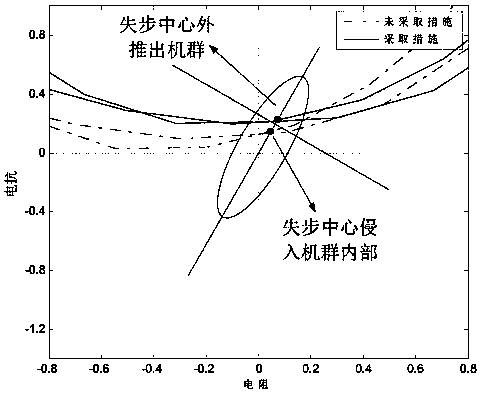

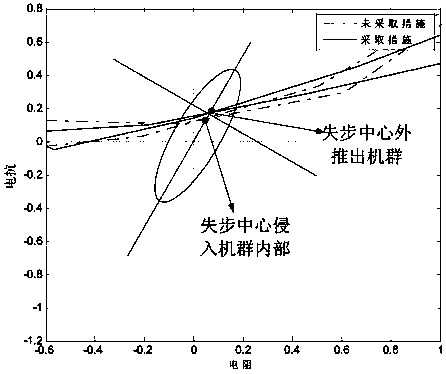

Flexible extrapolation method under out-of-step center machine group intrusion based on thyristor controlled series compensation parameter adjustment

ActiveCN110429646AEasy accessPracticalFlexible AC transmissionSingle network parallel feeding arrangementsSeries compensationInstability

The invention provides a flexible extrapolation method under out-of-step center machine group intrusion based on thyristor controlled series compensation parameter adjustment. The method is characterized by, under the internal scene of out-of-step center machine group intrusion, calculating system voltage distribution, determining an out-of-step center position coefficient equation, calculating and adjusting reactance parameters of a TCSC (thyristor controlled series compensation) device, verifying non-parallel resonance and transient stability of the system, determining a specific trigger angle adjustment scheme of the TCSC device and realizing out-of-step center machine group extrapolation. The method is a flexible control strategy without loss of units and load, is simple and reliable in principle and does not cause system instability, and is easy to realize in electric power engineering.

Owner:CHINA THREE GORGES UNIV

High-ground-stress large-deformation tunnel release-resistance combined primary support system and construction method

ActiveCN109779654AImprove stabilityReduced lateral free lengthUnderground chambersTunnel liningLarge deformationSupport system

The invention discloses a high-ground-stress large-deformation tunnel release-resistance combined primary support system and a construction method. The system comprises a primary support body which isa steel arch frame and an anchor net spraying combined support system matched with the steel arch frame, the primary support body is provided with a plurality of stress release windows in the side wall section of a tunnel, and the stress release windows located on each side of the primary support body are arranged at intervals in the longitudinal direction of the tunnel. The invention further discloses a construction method of the high-ground-stress large-deformation tunnel release-resistance combined preliminary support system. The system and method have the beneficial effects that non-synchronous deformation of surrounding rock and the primary support body is achieved, deformation of a portion, with a maximum deformation, of the primary support body before the primary support body is looped is effectively reduced, and damage to the primary support body before the primary support body is looped is avoided.

Owner:中铁隧道局集团建设有限公司

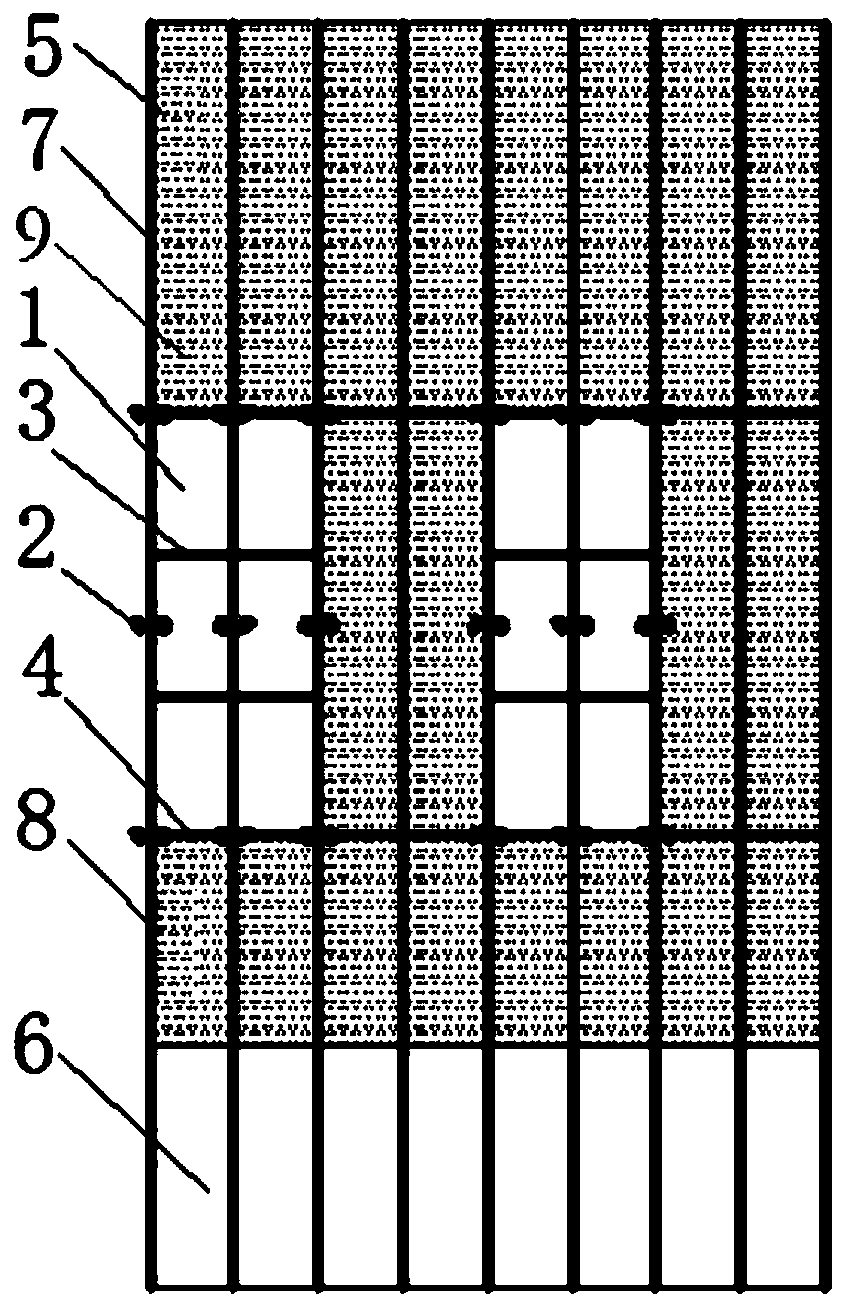

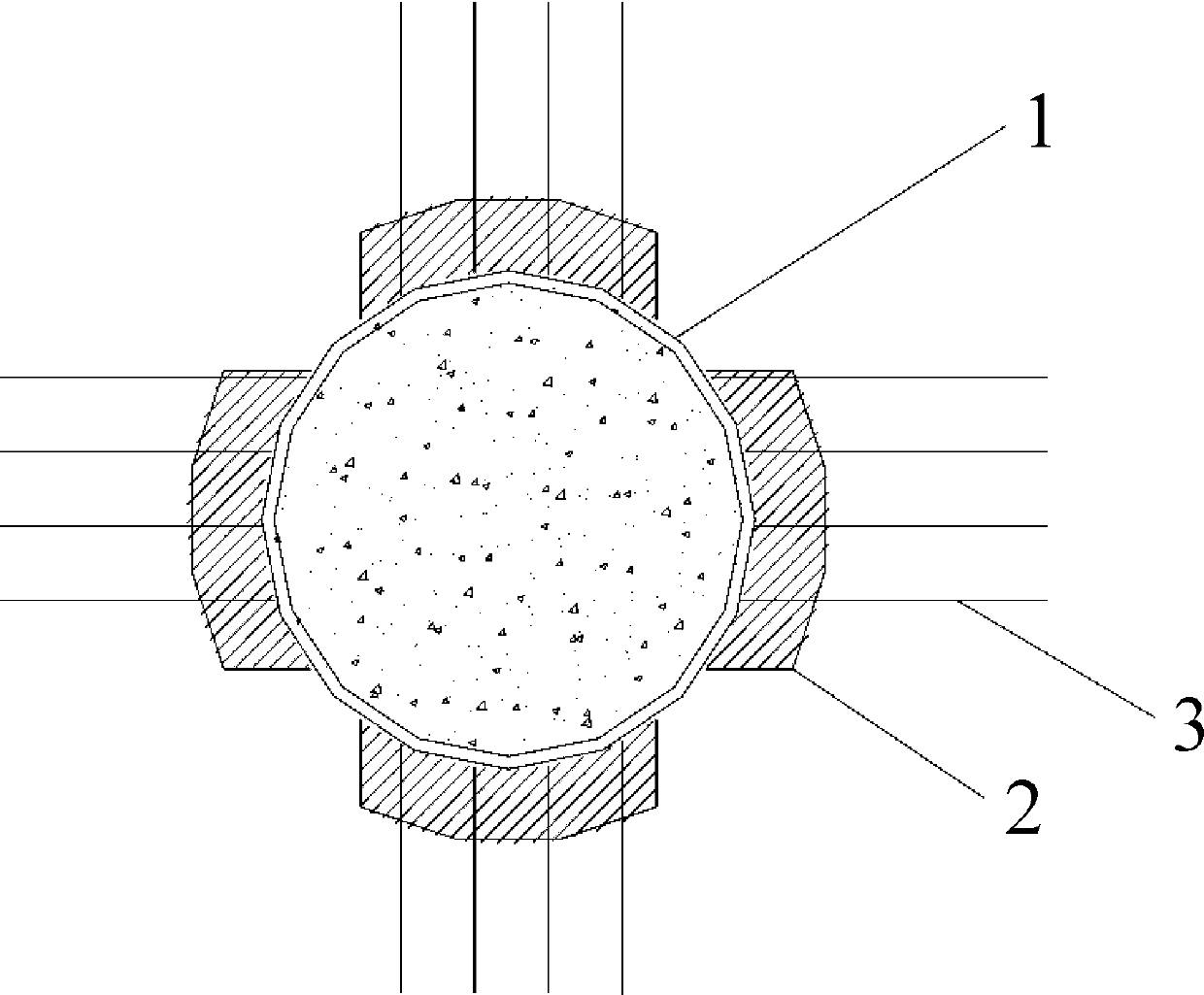

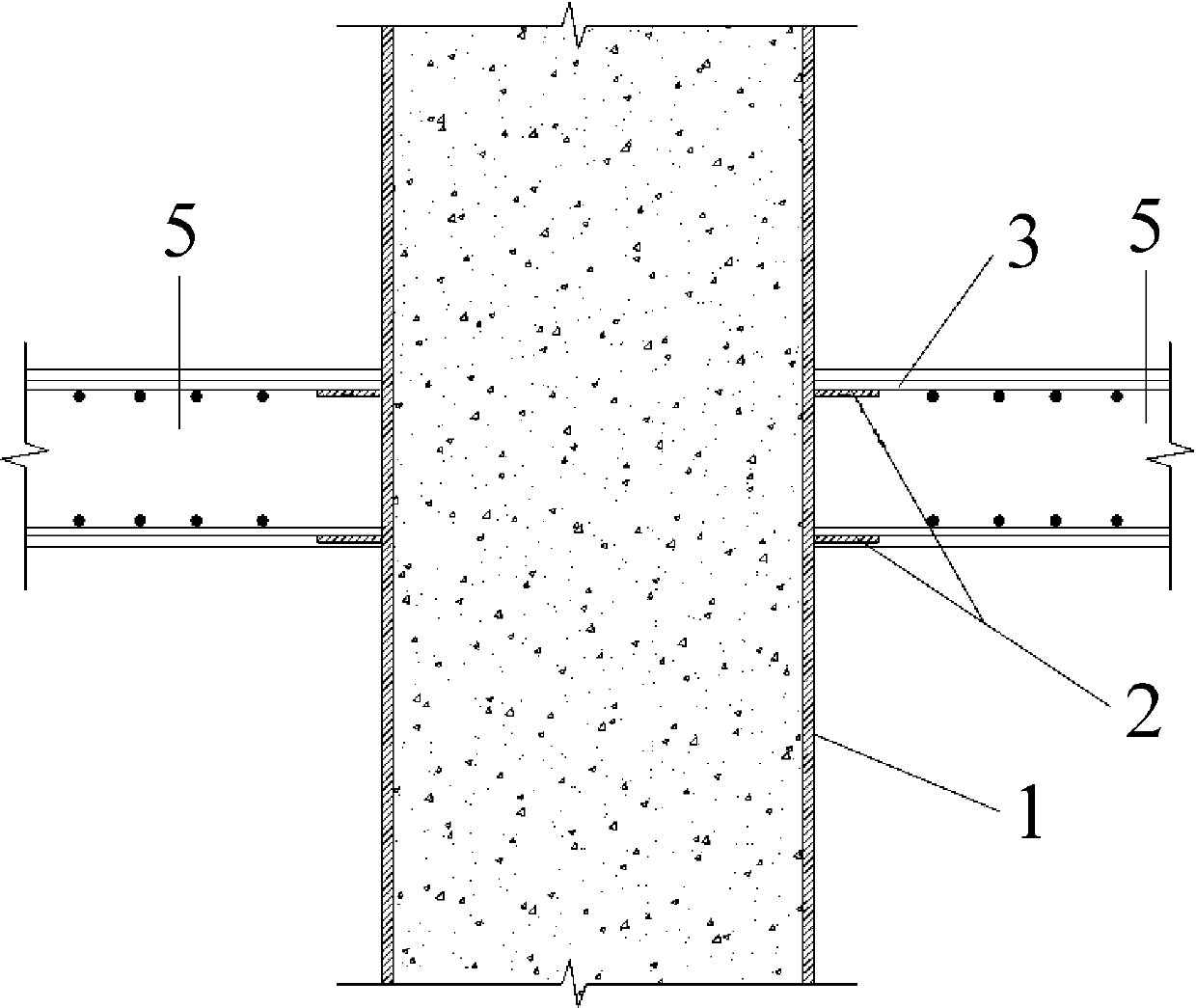

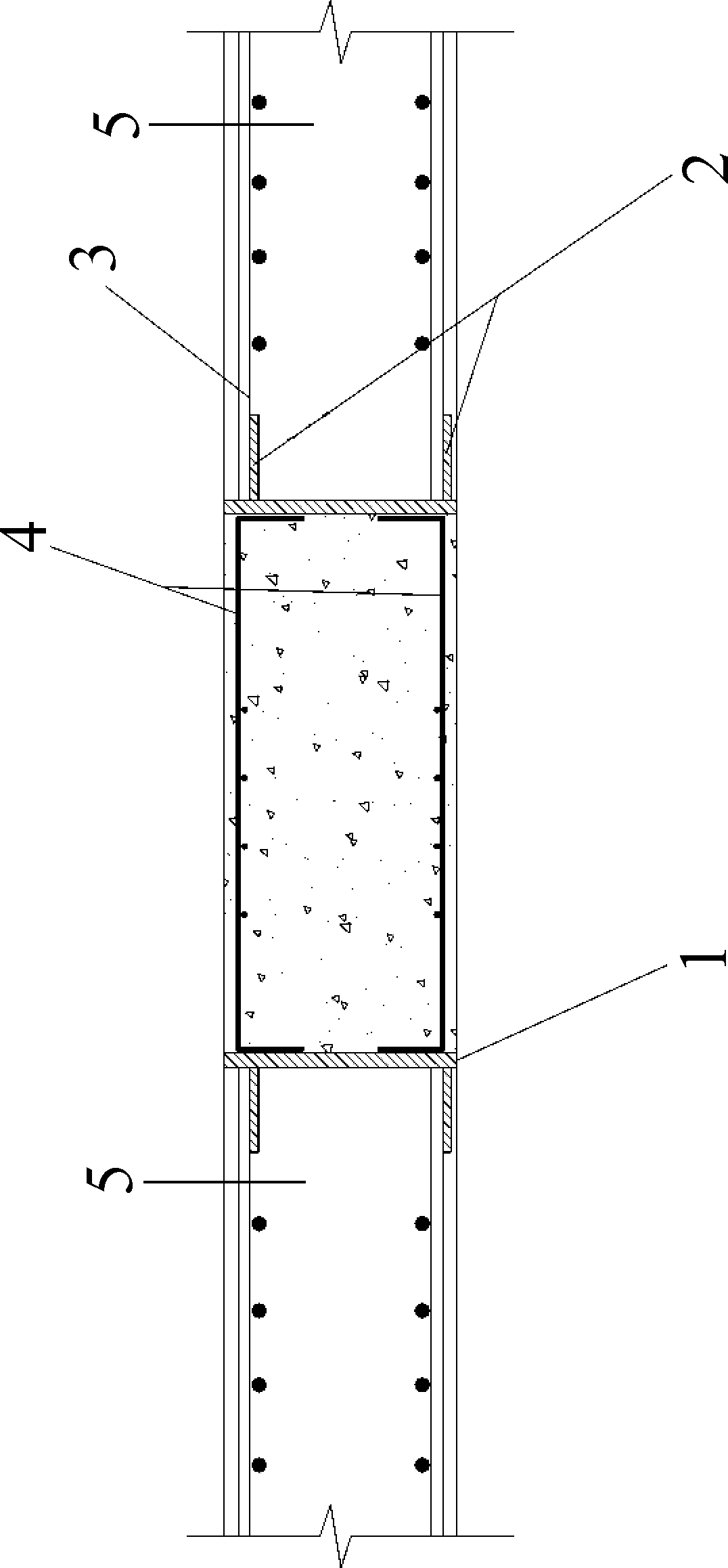

Reinforcing steel bar processing apparatus used for foundation pit support column and floor slab joint and usage method thereof

The invention relates to the field of a special-purpose connecting piece used for a floor slab structure, and specifically relates to a reinforcing steel bar processing apparatus used for a foundationpit support column and a floor slab joint and a usage method thereof. The reinforcing steel bar processing apparatus used for the foundation pit support column and the floor slab joint includes pipecolumns (1), and is characterized in that apparatus further comprises connecting plates (2), outer reinforcing steel bars (3) and inner reinforcing steel bars (4), and the inner ends of the connectingplates (2) are attached and fixed to the outer side surfaces of the pipe columns (1); the outer reinforcing steel bars (3) are all fixed on the connecting plates (2); and the inner reinforcing steelbars (4) are embedded in inner cavities of the pipe columns (1). The reinforcing steel bar processing apparatus used for the foundation pit support column and the floor slab joint and the usage methodthereof are characterized by being implemented in order according to the following steps: a. fixing the connecting plates; b. pouring a floor slab; c. cutting off the pipe columns; and d. pouring thepipe columns. The apparatus and the method are simple in structure, are convenient to construct, enable materials to be saved, and are safe and reliable.

Owner:CHINA MCC20 GRP CORP

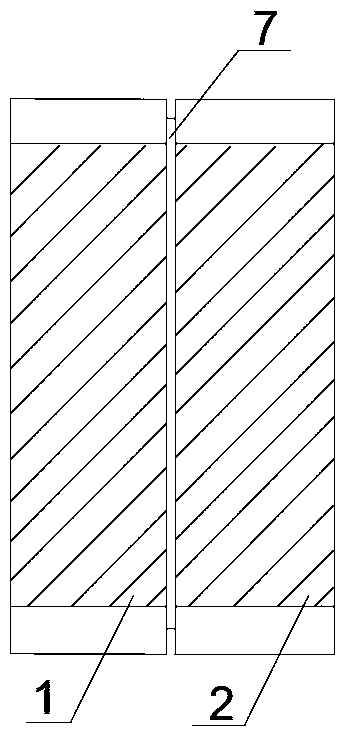

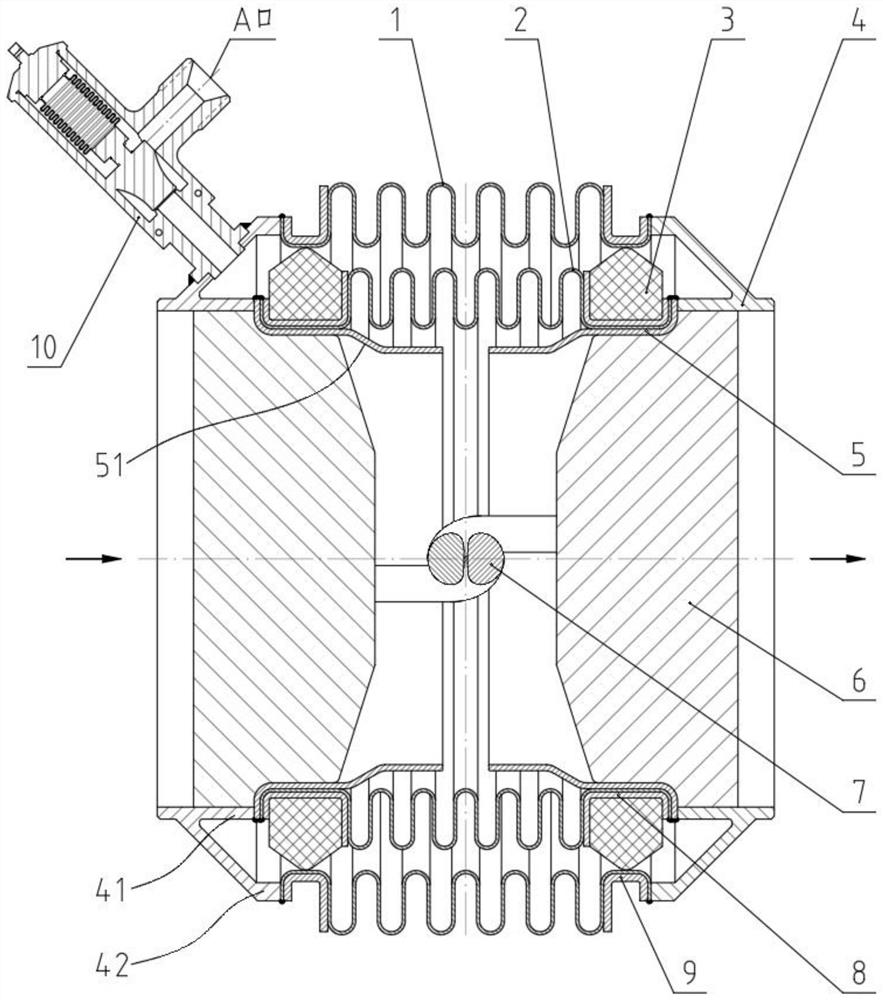

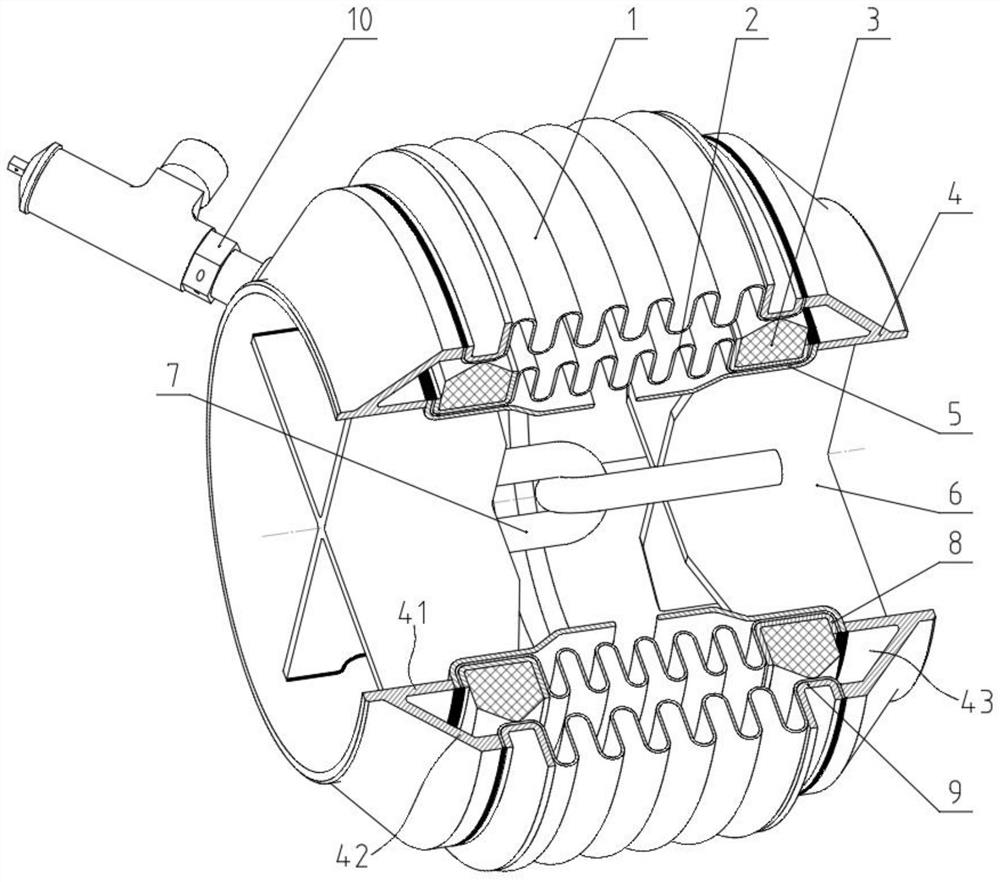

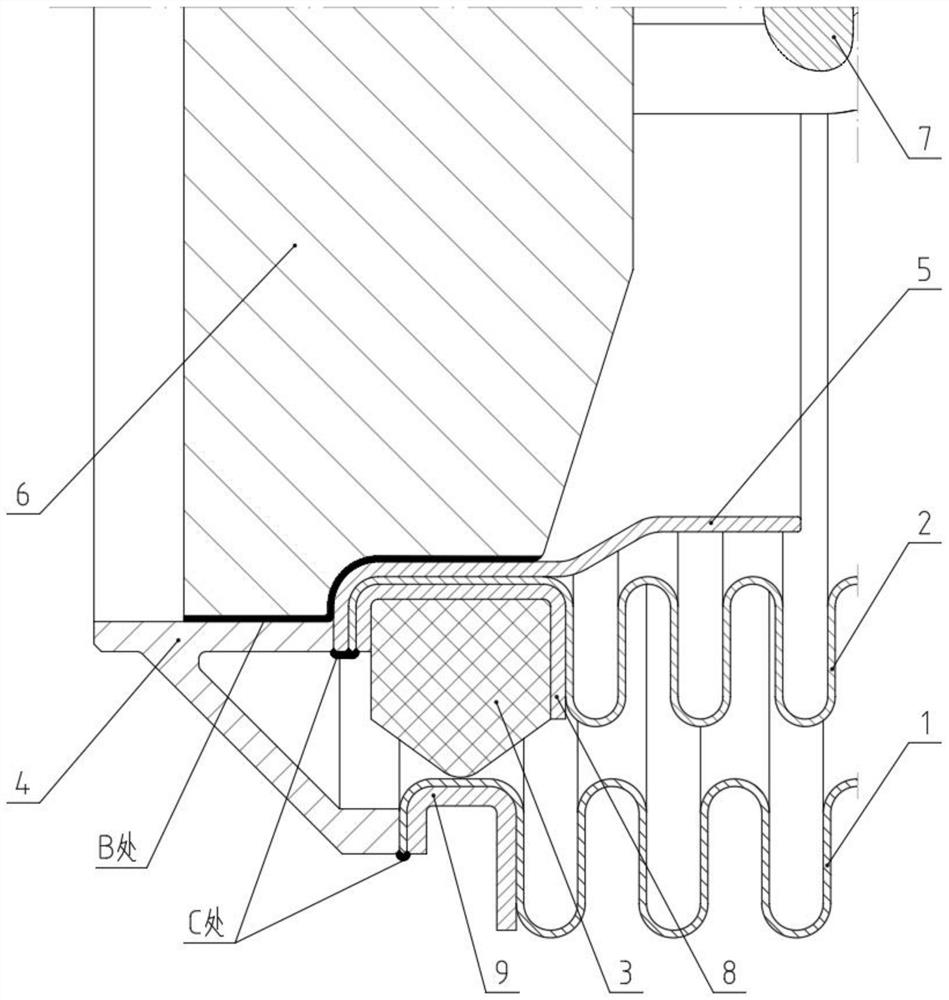

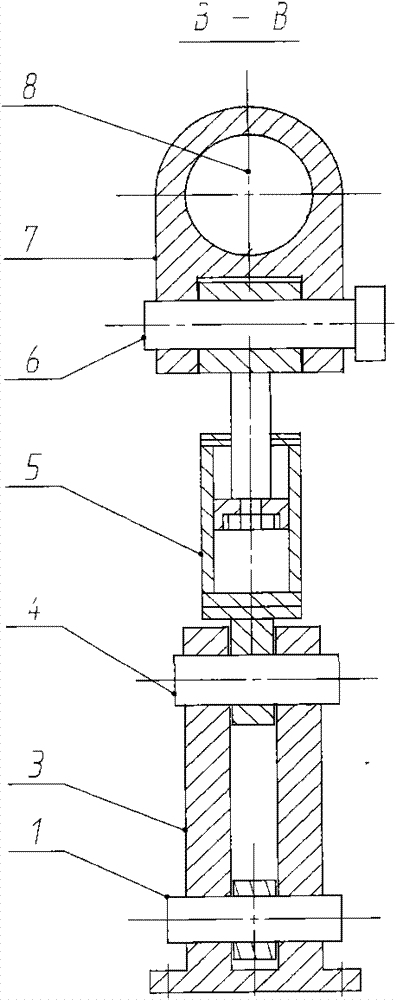

Pipeline compensator with inner support

PendingCN111649187AWon't lose stabilityCompact structurePipeline expansion-compensationEngineeringMechanical engineering

The invention discloses a pipeline compensator with an inner support. The pipeline compensator with the inner support comprises a corrugated pipe body, wherein connecting flanges are fixedly arrangedat two ends of the corrugated pipe body, a bracket is fixedly connected to the inner surface of each connecting flange, connecting rings are fixedly connected to one sides, close to each other, of thetwo brackets, and one ends, close to each other, of the two connecting rings are hooked together. The pipeline compensator with the inner support is compact in structure, good in compensation performance and free of instability.

Owner:安徽九州云箭航天技术有限公司

Bridge car

The invention discloses a bridge car. The bridge car is operated by a plurality of bridge pier tops being specially provided with electric I-shaped wheel type rollers to support and push a single-segment carriage with a rigid length greater than 2A, wherein an adjacent interval A of the bridge pier tops is over 10 meters, and occupied ground is less and no bridge body stretches across to obstructscenery. The bridge car is much cheaper than the bottom surface of a carriage with short rail tracks so as to be constructed straight and strong, and people and objects inside of the car are protectedto be safer and more comfortable. The bridge car is in contact with the rollers downwards so that foreign matters and dust which are adhered to the bridge car can be greatly reduced. Even driving toa turnout, a direction choosing roller which hangs down only from one side of the carriage can be used for crossing the outer side of a guide rod fixedly connected to the outer surface of a bearing atthe side end of a roller table to restrict the car from entering the turnout on the side. A plate turnout and a centimetre-wide turnout seam are disconnected. Caterpillar bands are wound between thebridge car and the rollers in a padding mode, and a cushion is easily added at the bottom of the bridge car to enable the operation more stable and efficient. Even the length of the carriage can be reduced to 1.5A to A to save money, the total cost and technical difficulty are close to ordinary trains, and no magnetic pollution of magnetic suspension or delikatny is achieved. The speed per hour can reach nearly 600,000 meters, and the distance to home after debarkation is far closer than an airport. A plurality of support-rod-type brakes are arranged at the bottom of the bridge car to supportthe bridge car to perform emergency brake by separating from the rollers. No driving device needs to be arranged in the carriage to reduce sources of danger.

Owner:罗晓晖

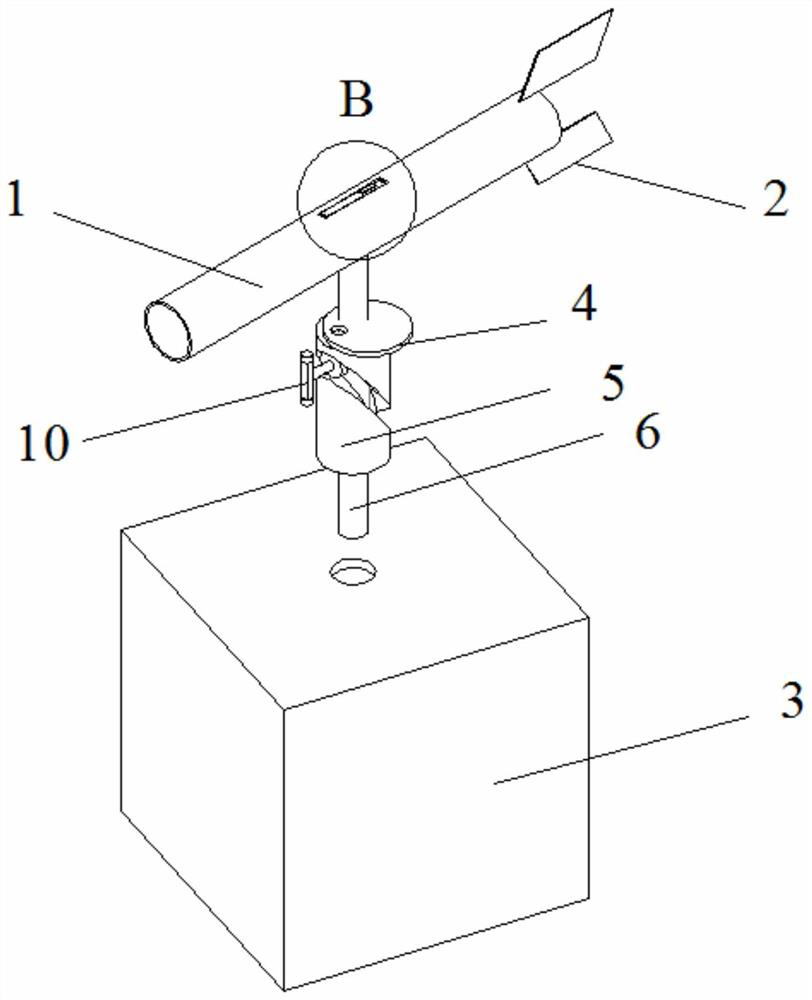

Fiber bragg grating wind speed and direction sensor

ActiveCN110988388AReduce collisionReduce lossIndication/recording movementUsing optical meansCantilevered beamFiber

The invention relates to a fiber bragg grating wind speed and direction sensor. The fiber bragg grating wind speed and direction sensor comprises a thin-walled cylinder and a packaging body, the upperpart at the middle of the thin-walled cylinder is hollowed out, a third constant strength cantilever beam is installed in the area, and fiber bragg grating sensors are symmetrically pasted to the central axes at the upper surface and lower surface of the third constant strength cantilever beam respectively. The sensor also includes a direction cam, a cylindrical cam and a push rod that are arranged in the packaging body, the upper part and lower part of one side in the packaging body are respectively connected to a horizontal constant strength cantilever beam, a vertical constant strength cantilever beam is hung and installed to the top side of the packaging body, fiber bragg grating sensors are pasted to both faces of the constant strength cantilever beams, and permanent magnets are arranged at the free ends of the constant strength cantilever beams so as to induce changes of magnetic force borne by the permanent magnets on the constant strength cantilever beams. The fiber bragg grating wind speed and direction sensor is light in structure and not easily damaged, and achieves real-time on-line monitoring of the wind speed and direction by utilizing the small size, electromagneticinterference resistance, good electrical insulation performance, large transportation capacity and other physical attributes of the fiber bragg grating.

Owner:SHIJIAZHUANG TIEDAO UNIV

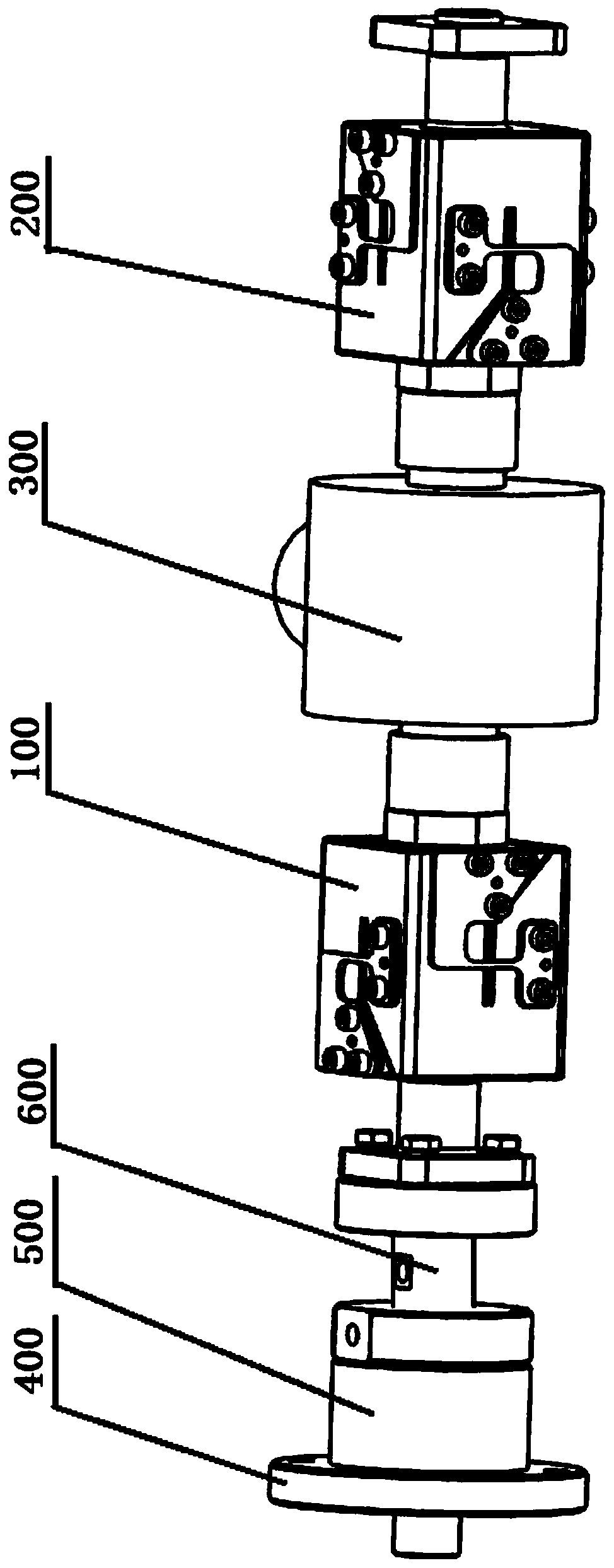

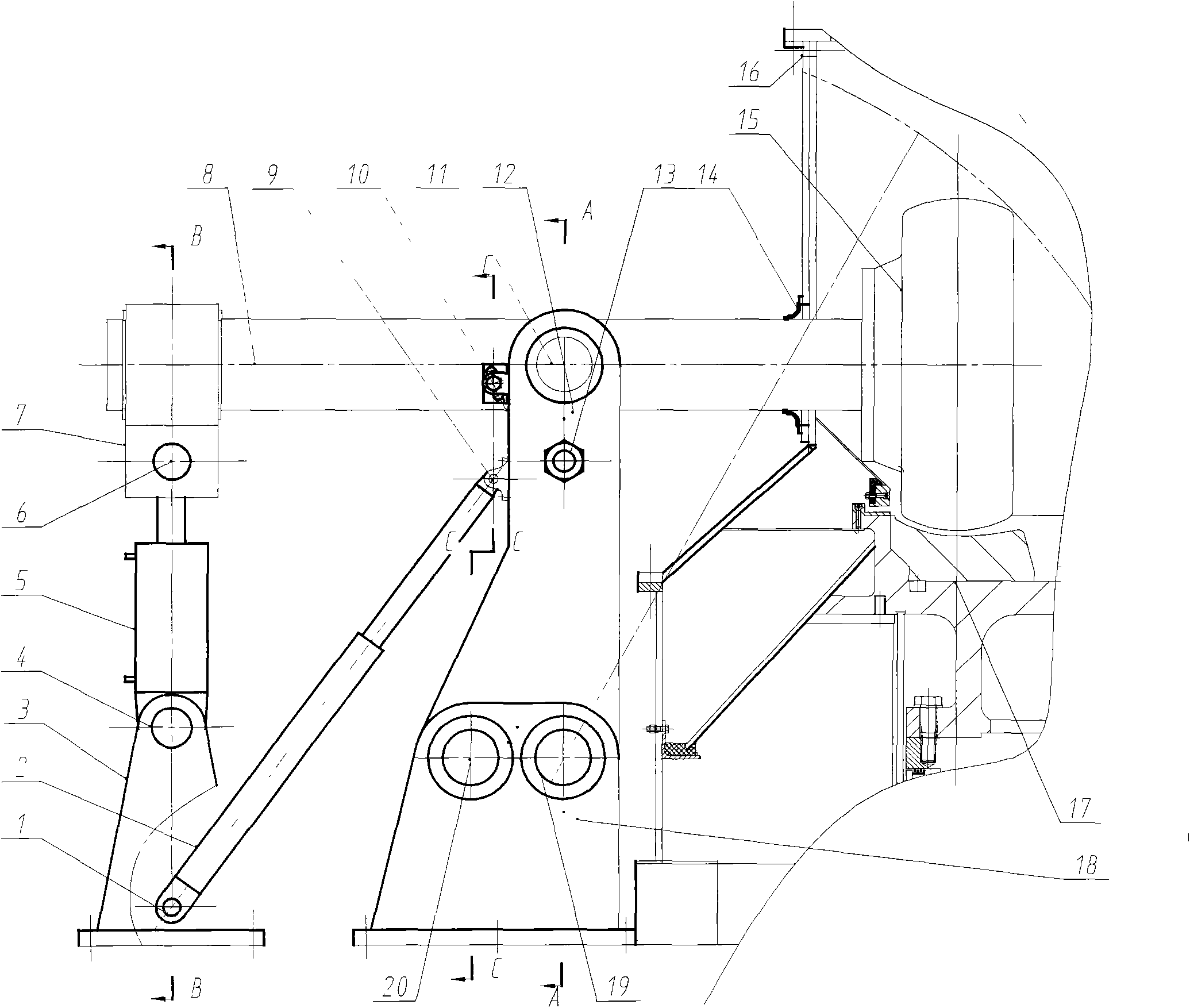

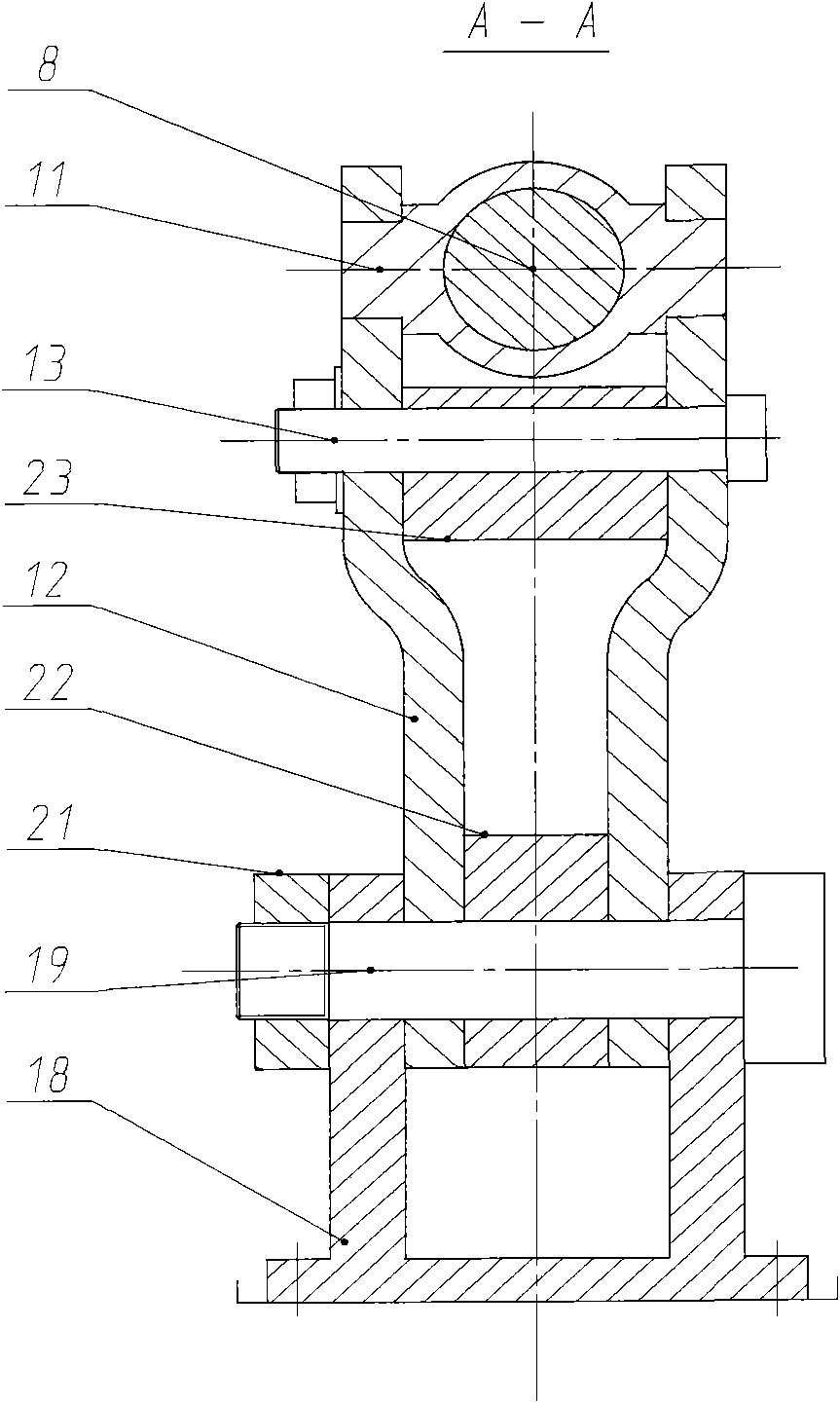

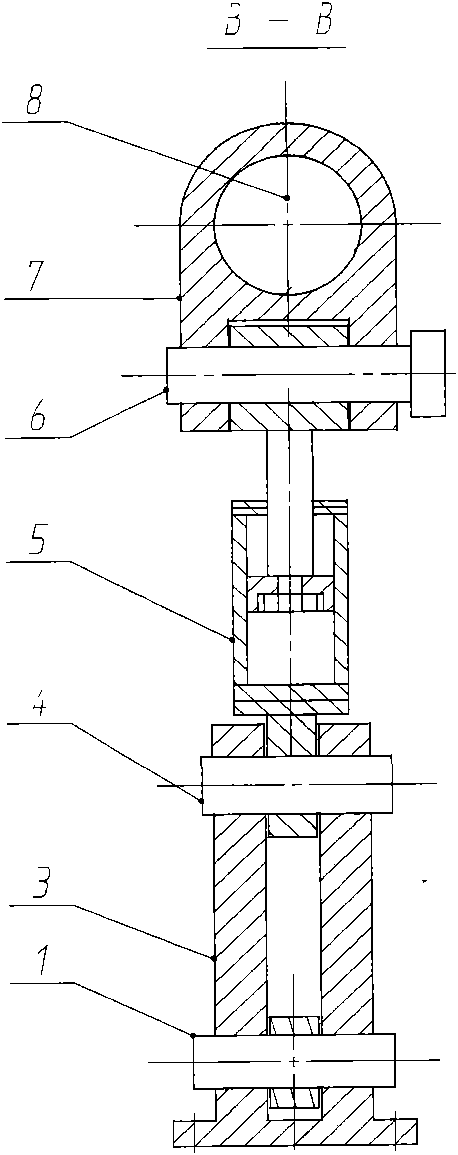

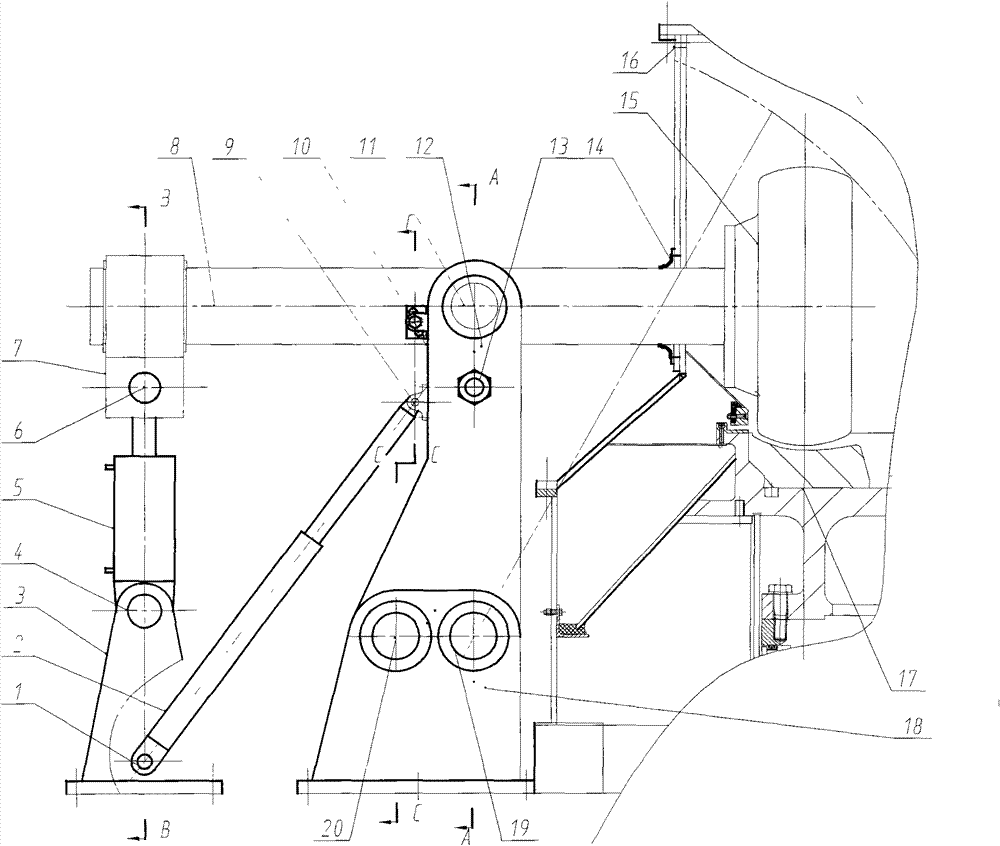

Grinding roller pressurization device for vertical mill

The invention discloses a grinding roller pressurization device for a vertical mill. The grinding roller pressurization device for the vertical mill comprises a compression roller component, a supporting device, a pressurization oil cylinder and an overhaul oil cylinder. The invention aims to provide the grinding roller pressurization device for the vertical mill which can overcome the disadvantages. During grinding, the hydraulic thrust vertically acts on a grinding roller pressurization rod, and oil flows into an operating travel rodless cavity to reduce oil supply pressure, hydraulic leakage and wear, and idle work loss of diagonal tension and member loads; and according to different motion requirements of grinding working condition and overhaul working condition on a grinding roller, the pressurization rod and a pressurization rod supporting plate are in hinged connection and in rigid connection, the pressurization rod supporting plate and a pressurization rod supporting base are in hinged connection and rigid connection, and the two modes correspond to each other in a staggered way, so that the load requirements of the supporting device during grinding are met, the turning space when the grinding roller is overhauled is also reduced, and the manufacturing cost of the vertical mill is reduced. The invention belongs to the field of technical equipment of powder engineering, and is applied to grinding materials of vertical mills.

Owner:王华业

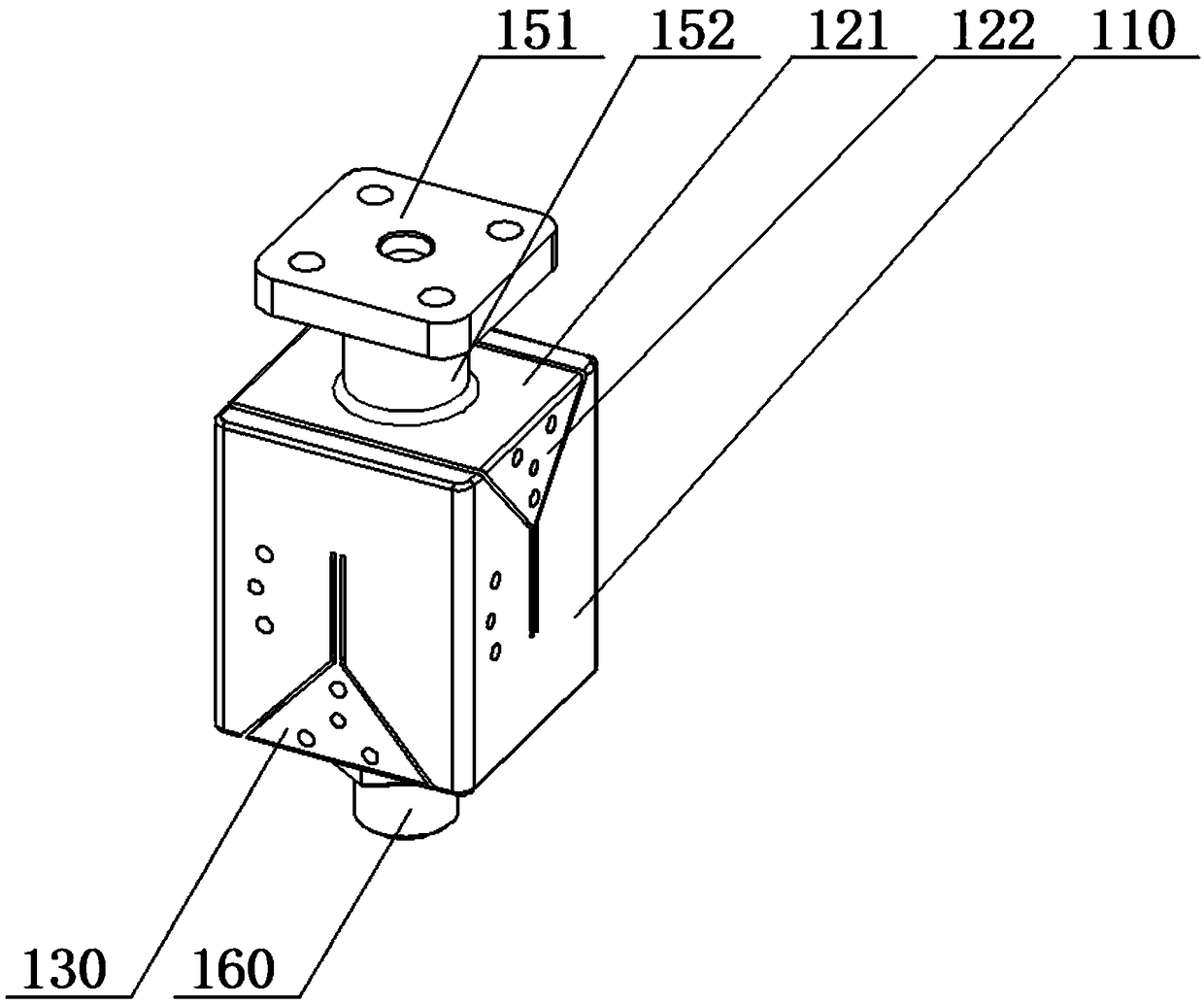

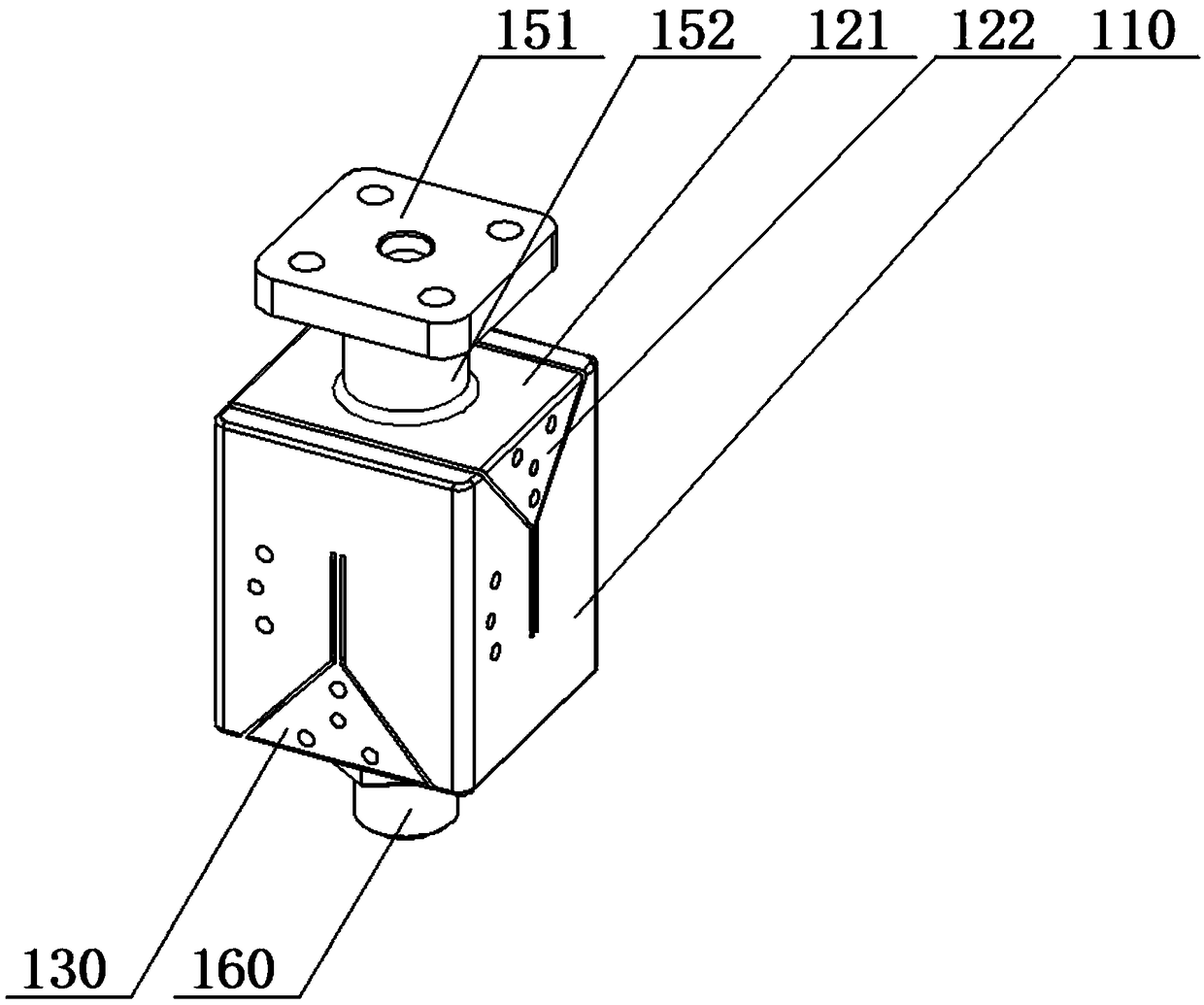

Universal flexible part

PendingCN109163908AImprove axial stiffnessReduce lateral stiffnessEngine testingEngineeringLeaf spring

The invention discloses a universal flexible part. A shell is of a hollow cuboid structure without a top surface and a bottom surface; a first main leaf spring and a second main leaf spring are the same in structure, the first main leaf spring comprises transverse leaf springs and axial leaf springs, two pieces of the axial leaf springs are arranged, and the two pieces of the axial leaf springs are fixedly connected to the transverse leaf springs respectively and are perpendicular to the transverse leaf springs; containing grooves used for containing the axial leaf springs are arranged in theleft surface, the right surface, the front surface and the rear surface of the shell; and the containing grooves in the left surface and the right surface of the shell are arranged at the tops of theleft surface and the right surface of the shell, and the containing grooves in the front surface and the rear surface of the shell are arranged at the bottoms of the front surface and the rear surfaceof the shell; the two pieces of the axial leaf springs of the first main leaf spring are matched with the containing grooves in the left surface and the right surface of the shell respectively, and the two pieces of the axial leaf springs of the second main leaf spring are matched with the containing grooves in the front surface and the rear surface of the shell respectively; and the four piecesof the axial leaf springs are fixedly connected to the left surface, the right surface, the front surface and the rear surface of the shell through supporting leaf springs respectively.

Owner:BEIJING AEROSPACE SANFA HIGH TECH +1

bridge car

The invention discloses a bridge car. The bridge car is operated by a plurality of bridge pier tops being specially provided with electric I-shaped wheel type rollers to support and push a single-segment carriage with a rigid length greater than 2A, wherein an adjacent interval A of the bridge pier tops is over 10 meters, and occupied ground is less and no bridge body stretches across to obstructscenery. The bridge car is much cheaper than the bottom surface of a carriage with short rail tracks so as to be constructed straight and strong, and people and objects inside of the car are protectedto be safer and more comfortable. The bridge car is in contact with the rollers downwards so that foreign matters and dust which are adhered to the bridge car can be greatly reduced. Even driving toa turnout, a direction choosing roller which hangs down only from one side of the carriage can be used for crossing the outer side of a guide rod fixedly connected to the outer surface of a bearing atthe side end of a roller table to restrict the car from entering the turnout on the side. A plate turnout and a centimetre-wide turnout seam are disconnected. Caterpillar bands are wound between thebridge car and the rollers in a padding mode, and a cushion is easily added at the bottom of the bridge car to enable the operation more stable and efficient. Even the length of the carriage can be reduced to 1.5A to A to save money, the total cost and technical difficulty are close to ordinary trains, and no magnetic pollution of magnetic suspension or delikatny is achieved. The speed per hour can reach nearly 600,000 meters, and the distance to home after debarkation is far closer than an airport. A plurality of support-rod-type brakes are arranged at the bottom of the bridge car to supportthe bridge car to perform emergency brake by separating from the rollers. No driving device needs to be arranged in the carriage to reduce sources of danger.

Owner:罗晓晖

Construction method of bollard protection structure on slope surface in water level fluctuation zone

ActiveCN111549726BStrong ability of erosionImprove structural stabilityClimate change adaptationCoastlines protectionPile capReinforced concrete

Owner:THREE GORNAVIGATION AUTHORITY +1

A fiber grating wind speed and direction sensor

ActiveCN110988388BReduce collisionReduce lossIndication/recording movementUsing optical meansFiberCantilevered beam

This application relates to a fiber grating wind speed and direction sensor, including a thin-walled cylinder and a package body. The upper middle part of the thin-walled cylinder is hollowed out, and a third equal-strength cantilever beam is installed in this area. The central axis of the upper and lower surfaces of the third equal-strength cantilever beam The fiber grating sensors are symmetrically pasted on the top respectively; it also includes a direction cam, a cylindrical cam and a push rod arranged in the package body, and a horizontal equal-strength cantilever beam is respectively connected to the upper and lower parts of the inner side of the package body, and is hung and installed on the top side of the package body A vertical equal-intensity cantilever beam, fiber grating sensors are pasted on both sides of the equal-intensity cantilever beam, and a permanent magnet is provided at the free end to sense the magnetic force change of the permanent magnet on the equal-intensity cantilever beam. The application has a light structure and is not easy to be damaged, and realizes real-time online monitoring of wind speed and direction by utilizing the physical properties of fiber gratings such as small size, anti-electromagnetic interference, good electrical insulation performance and large transportation capacity.

Owner:SHIJIAZHUANG TIEDAO UNIV

Grinding roller pressurization device for vertical mill

The invention discloses a grinding roller pressurization device for a vertical mill. The grinding roller pressurization device for the vertical mill comprises a compression roller component, a supporting device, a pressurization oil cylinder and an overhaul oil cylinder. The invention aims to provide the grinding roller pressurization device for the vertical mill which can overcome the disadvantages. During grinding, the hydraulic thrust vertically acts on a grinding roller pressurization rod, and oil flows into an operating travel rodless cavity to reduce oil supply pressure, hydraulic leakage and wear, and idle work loss of diagonal tension and member loads; and according to different motion requirements of grinding working condition and overhaul working condition on a grinding roller, the pressurization rod and a pressurization rod supporting plate are in hinged connection and in rigid connection, the pressurization rod supporting plate and a pressurization rod supporting base are in hinged connection and rigid connection, and the two modes correspond to each other in a staggered way, so that the load requirements of the supporting device during grinding are met, the turning space when the grinding roller is overhauled is also reduced, and the manufacturing cost of the vertical mill is reduced. The invention belongs to the field of technical equipment of powder engineering, and is applied to grinding materials of vertical mills.

Owner:王华业

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com