Detecting device for deformation joint leakage of circular tunnels

A detection device and deformation joint technology are applied in the field of tunnel leakage detection, which can solve the problems of leakage at joints, hidden dangers, and unfavorable long-term safe operation of tunnels, so as to improve detection efficiency, avoid loss of human and material resources, and improve detection efficiency. The result is obvious and intuitive

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

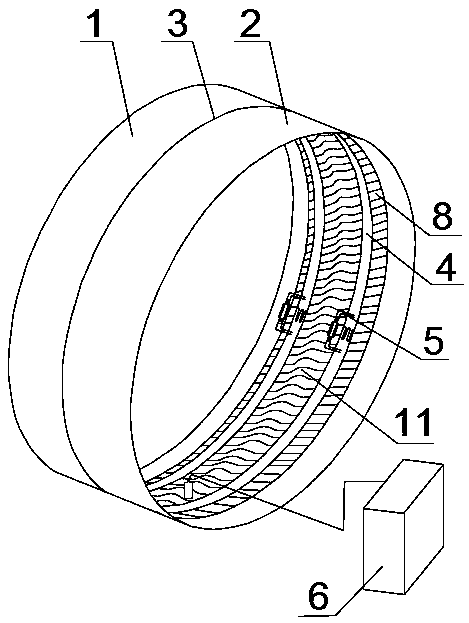

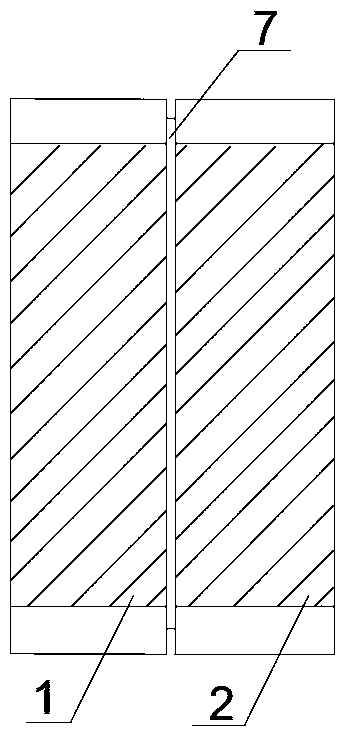

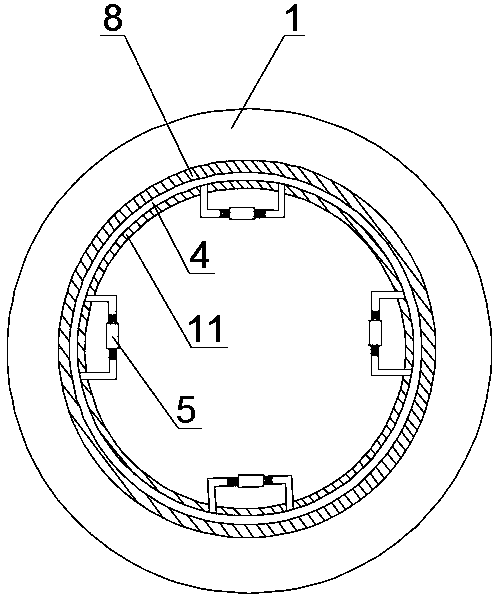

[0028] Such as figure 1 As shown, a detection device for the leakage of circular tunnel deformation joints, the device is detachably installed at the expansion joint 3 between the front circular tunnel 1 and the rear circular tunnel 2, and the expansion joint 3 is provided with The water stop sheet 7 tightly combined with the circular tunnels on both sides, such as figure 2 As shown, the water stop sheet 7 is located in the middle part of the expansion joint 3, and both left and right are embedded in the concrete lining the tunnel. The detection device includes an annular rubber belt 8, an air pressure detection device 6 and two sets of ring-shaped toothed connection steel plates 4, wherein, The outer diameter of the annular rubber belt 8 is consistent with the inner diameter of the circular tunnel, the outer diameter of the toothed connecting steel plate 4 is consistent with the inner diameter of the annular rubber belt 8, the annular rubber belt 8 is attached to the inner w...

Embodiment 2

[0030] The annular rubber belt 8 is provided with a hollow rubber hemisphere 9 that protrudes toward the center of the tunnel. The rubber hemisphere 9 and the annular rubber belt 8 form an integral structure, and the interior communicates with the closed space, and is located between two sets of toothed connecting steel plates 4. The top of the hemisphere 9 is provided with an inflation valve, and the air pressure detection device 6 is detachably connected to the rubber hemisphere 9 by connecting the inflation valve to the rubber hemisphere 9, so as to detect the air pressure in the confined space.

Embodiment 3

[0032]This embodiment is a further optimization of Embodiment 1: in this embodiment, two parallel annular rubber rings 10 are respectively provided on both sides of the contact surface between the annular rubber belt 8 and the inner wall of the circular tunnel, and the two annular rubber rings 10 on each side A recessed area is formed between the rubber rings 10, and the tightening positions of the two groups of toothed connecting steel plates 4 correspond to the recessed areas respectively, and the annular rubber ring 8 is squeezed by the toothed connecting steel plates 4 to the annular rubber belt 8. 10 is in an open state on both sides and tightly combined with the inner wall of the circular tunnel, which ensures the tightness of the device during detection.

[0033] The method of use of the present invention is as follows: when testing, the annular rubber belt is closely attached to the tunnel, and then the toothed connecting steel plate is used to firmly clamp the annular ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com