A method for judging the damage of a shield machine disc hob

A disc-shaped hob and shield machine technology, which is applied in the direction of earth drilling, mining equipment, tunnels, etc., can solve the problems of blindness of tools, low efficiency, and tool judgment, so as to reduce investigation time, improve accuracy, well-designed effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

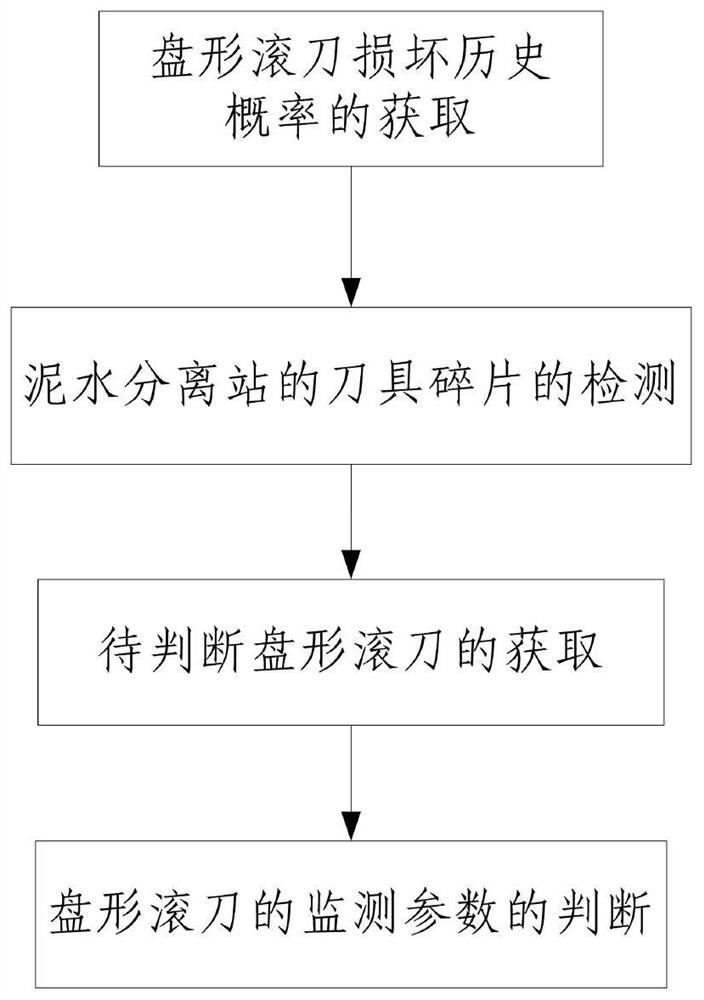

[0051] like figure 1 As shown, the present invention comprises the following steps:

[0052] Step 1. Obtaining the historical probability of damage to the disc hob:

[0053] Step 101, number each disc hob on the excavation cutter head, obtain the 1st disc hob, ..., the i th disc hob, ..., the I th disc hob, And mark the respective number marks on the circumference of the cutter ring of one disc hob; wherein, i and I are both positive integers, and 1≤i≤I;

[0054] Step 102, setting the initial value of the damage times of the i-th disc hob to zero;

[0055] Step 103: During the historical excavation process of the shield machine, when the excavation parameters are abnormal for the mth time, manually check each disc hob on the excavation cutter head for the mth time. Damage times n of i disc hob i plus 1;

[0056] Step 104: According to the method described in Step 103, until when m=M, the judgment of each disc hob in the historical excavation process is completed, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com