Cosmetic grade water-based pigment composite dispersant and production method thereof and liquid pen

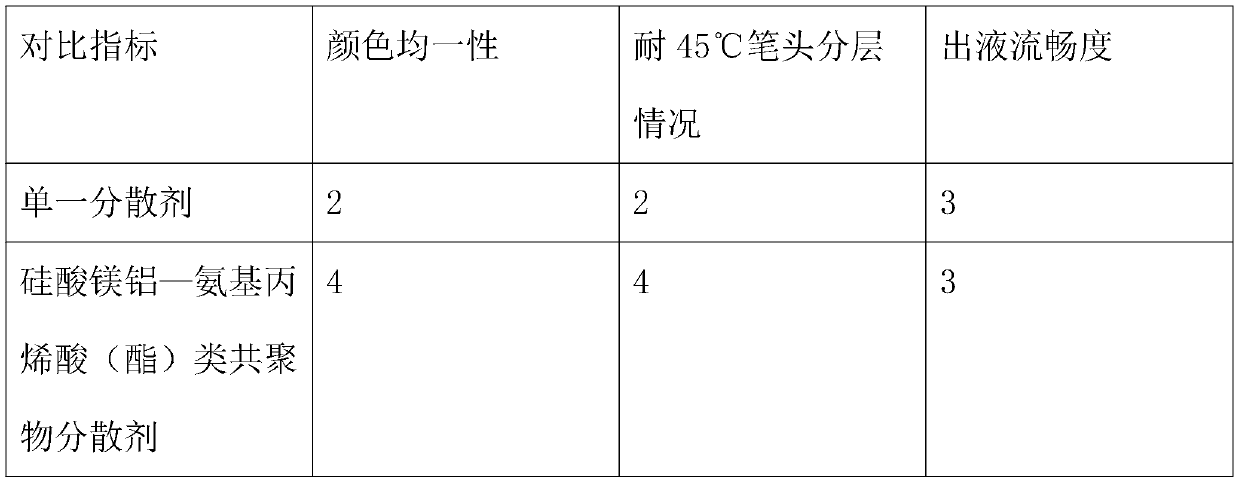

A composite dispersant and water-based pigment technology, applied in cosmetics, cosmetic preparations, cosmetic preparations, etc., can solve problems such as clogging of the pen tip, pigment hardening of the finished pen tip of a liquid pen, uneven color, etc., to achieve uniform covering power, product Fine tissue, improve the effect of suspension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0036] Take a clean 250ml beaker and add 90ml of deionized water, then weigh 5g of magnesium aluminum silicate solid with a balance, and add the magnesium aluminum silicate solid to the beaker under constant stirring with a glass rod until the solid is completely wetted. Add 5ml of aminoacrylic acid (ester) copolymer to the beaker with a plastic dropper, and finally use a high-speed homogeneous mixer to stir at a speed of 10,000rpm. After 10 minutes of homogenization time, a non-transparent white 5% magnesium aluminum silicate can be obtained. - Aminoacrylic acid (ester) copolymer water dispersant sol.

[0037] A liquid pen comprising the above-mentioned dispersant, comprising the following components in mass percent: polyol 10%; preservative 1%; deionized water 30%; dispersant 10%; water-based pigment 29%; film-forming agent 20%. Pre-mix polyols, preservatives, deionized water, dispersants, and water-based pigments in a beaker under stirring with a glass rod, and then grind t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com