Reinforcing steel bar processing apparatus used for foundation pit support column and floor slab joint and usage method thereof

A foundation pit support and processing device technology, applied in the direction of construction, building structure, etc., can solve the problems of easy instability, large vertical force on braces or trestles, lattice columns that cannot meet the use requirements and safety requirements, etc. problems, achieve the effect of material saving and convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

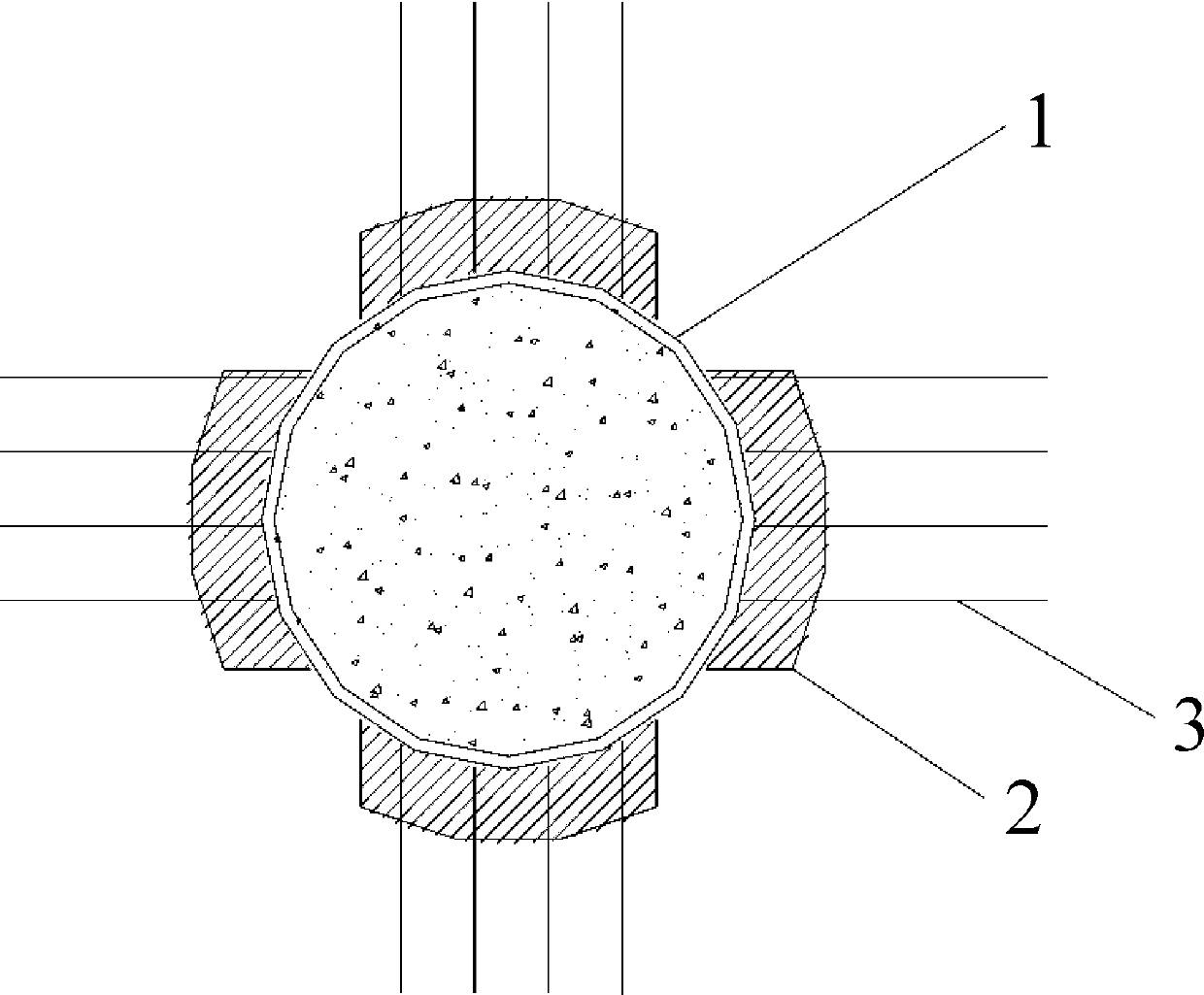

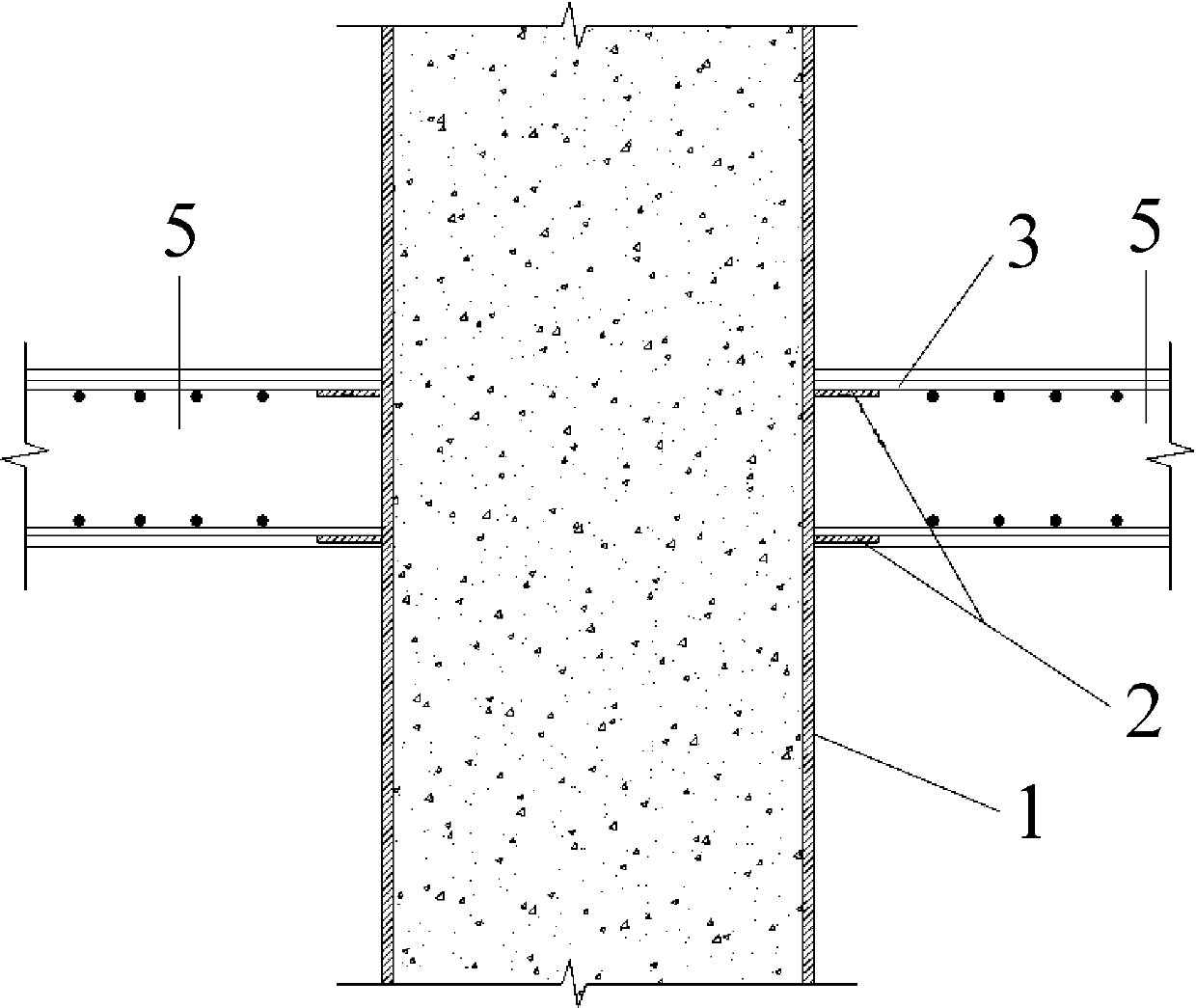

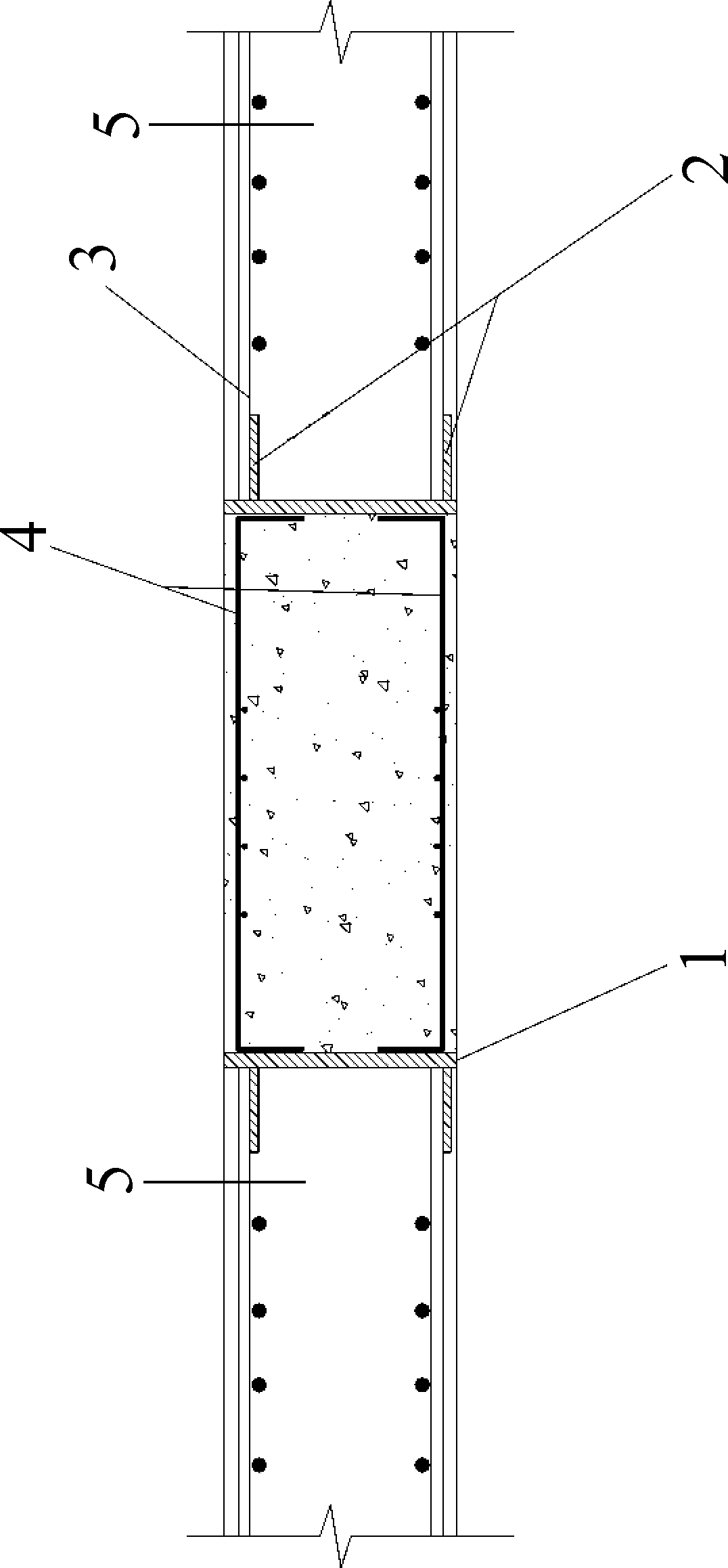

[0025] A steel bar treatment device used for foundation pit supporting columns and floor joints, including pipe column 1, connecting plate 2, outer steel bar 3 and inner steel bar 4, such as Figure 1 ~ Figure 3 As shown, the specific structure is:

[0026] The pipe column 1 is the concrete pouring in the wall of the steel pipe;

[0027] The connecting plate 2 is arranged in two layers along the central axis of the pipe column 1. Each layer is provided with four connecting plates 2. The connecting plate 2 is made of an arc steel plate with a radial width of 150 mm and a thickness of 10 mm. The connecting plate 2 surrounds the pipe column 1. The outer side walls of the connecting plate 2 are evenly distributed, the inner end of the connecting plate 2 and the outer side surface of the pipe string 1 are matched with each other, the inner end of the connecting plate 2 is attached and fixed on the outer surface of the pipe string 1, and the connecting plate 2 and the pipe string 1 are p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com