Heavy-load coupler with safety stop and low transverse force properties

A lateral force and coupler technology, applied in railway car body parts, traction devices, transportation and packaging, etc., can solve the problems of coupler instability and driving safety accidents, and achieve the effect of ensuring safety and good dynamic performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with drawings and embodiments.

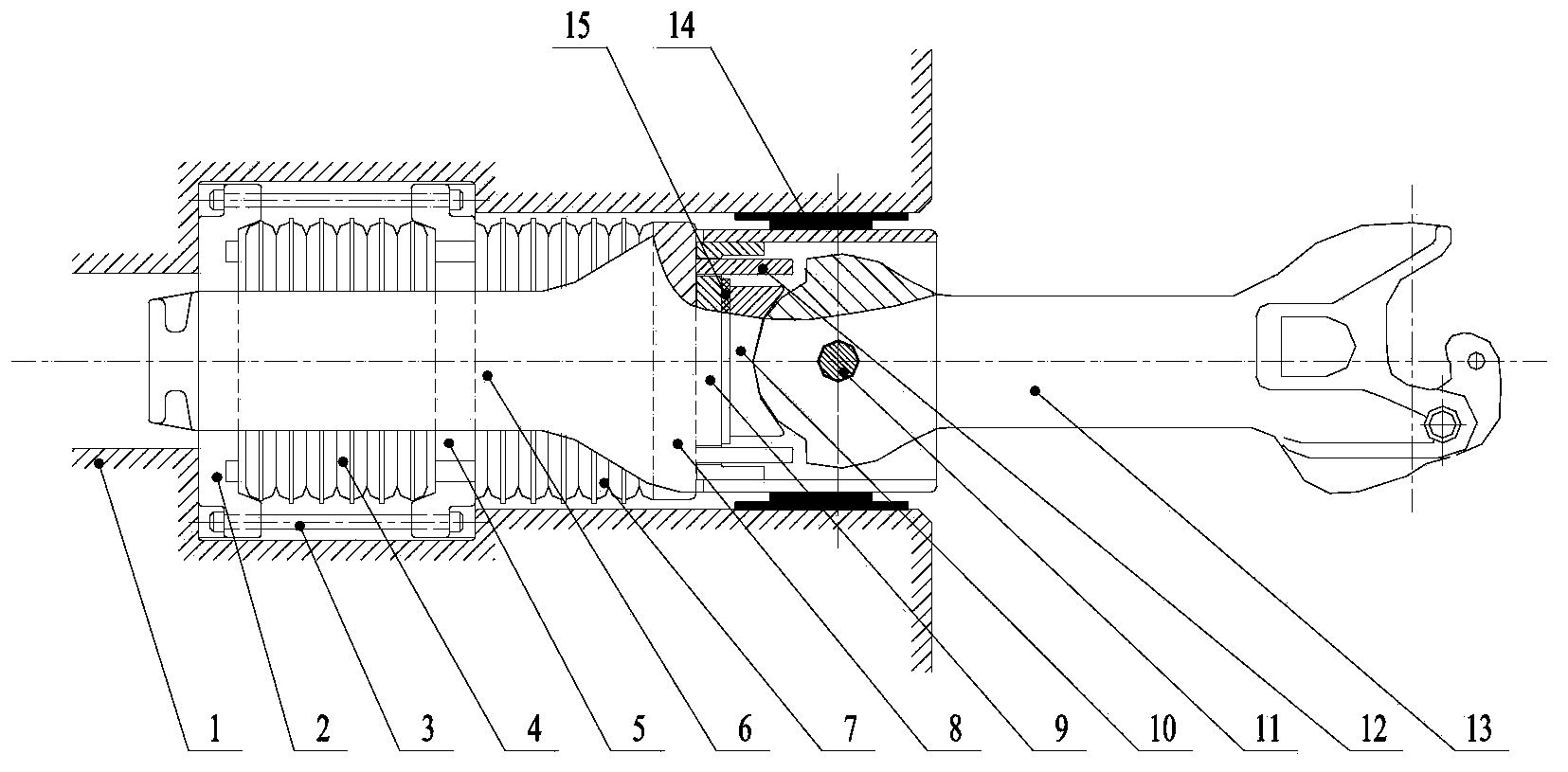

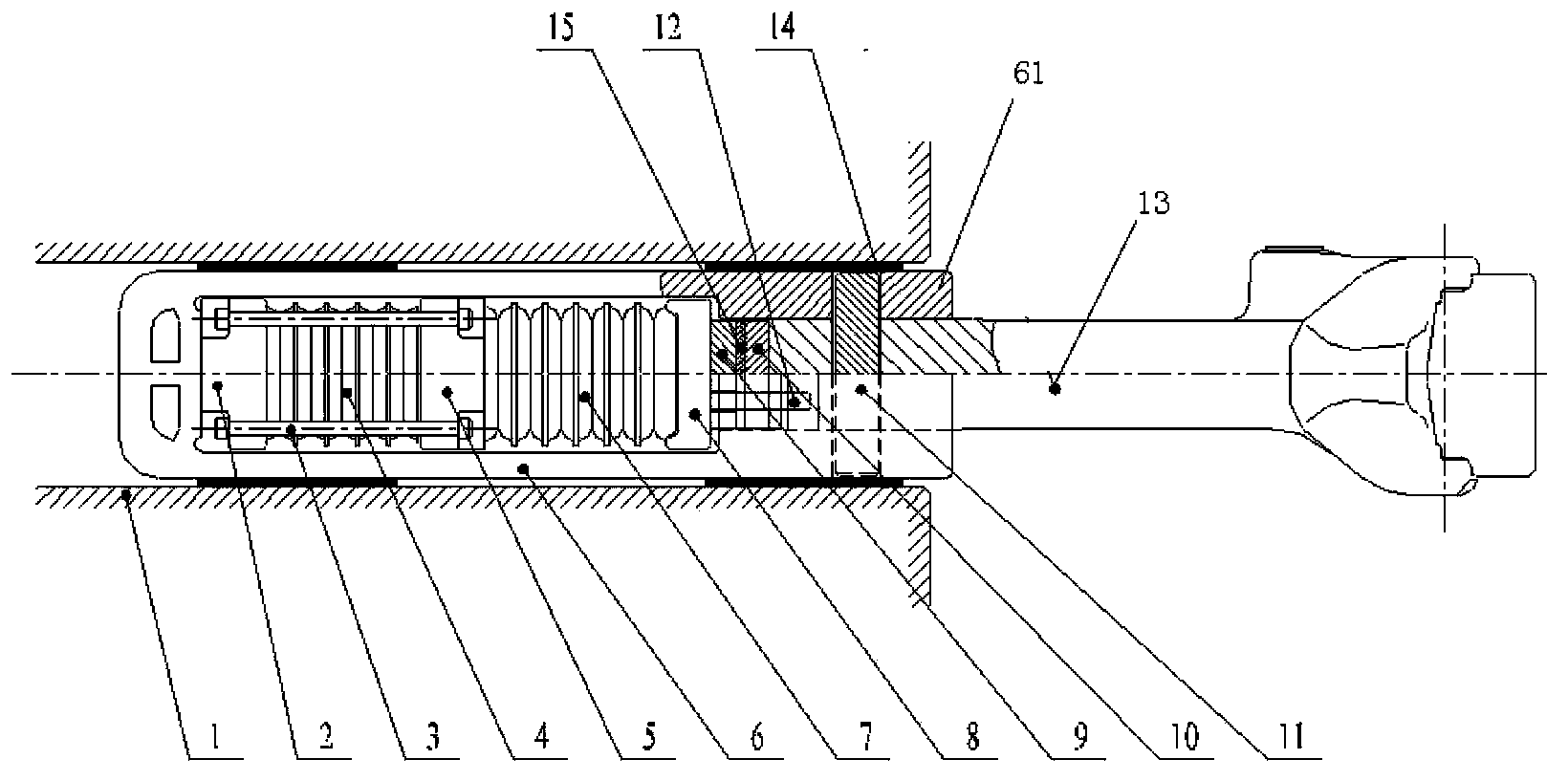

[0011] Depend on figure 1 and figure 2 It can be seen that the present invention is mainly composed of coupler 13, coupler slowing device, front slave plate 10, block 12 and coupler pin 11, and the coupler slowing device is mainly composed of two buffers, dividing plate and coupler tail frame 6. The hook slowing device is fixedly installed on the car body mount 1. The first-stage cement buffer 4 is positioned and pre-compressed by the bottom partition 2 , the middle partition 5 and four bolts 3 ; the second-stage cement buffer 7 is positioned by the coupler frame 6 and the top partition 8 and pre-compressed. The coupler pin 11 connects the coupler 13 with the coupler frame 6 through the pin hole placed on the coupler frame edge 6, and the coupler 13 can rotate around the coupler pin 11. Between the top partition plate 8 and the coupler 13 are provided a front slave ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com