Flexible combined spliced target ship

A combined and flexible technology, applied in the direction of targets, hulls, movable targets, etc., can solve the problems of inapplicable plateau uninhabited land lakes and remote sea areas, complex structure of target ships, high cost, etc., to avoid sinking and pollution of the hull The risk of the water environment, good separate transportation ability and anti-strike ability, and the effect of simple and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

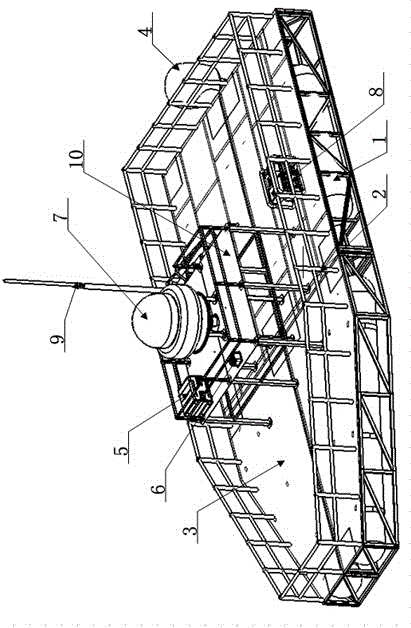

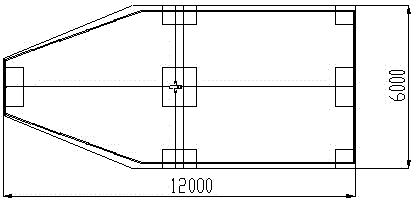

[0024] Embodiment 1: see figure 1 , figure 2 , a flexible combined splicing target ship, the splicing target ship includes a target ship platform, a ship-mounted installation bracket 10 arranged on the target ship platform, and the ship-mounted installation bracket 10 is provided with automatic navigation control equipment 5, Heading attitude measurement equipment 6, wireless communication equipment 9 and radar radiation source / interference source simulation equipment 7, described heading attitude measurement equipment 6 is a GPS / BD type heading attitude measurement unit, installed on the central axis of the hull, and automatically navigated through the serial port The control equipment 5 is connected to measure the position and attitude changes of the hull. The target ship platform includes a platform steel plate 3, guardrails 2 are arranged around the platform steel plate 3, and a unit body assembly 1 is arranged below the platform steel plate 3. . The unit body assembly ...

Embodiment 2

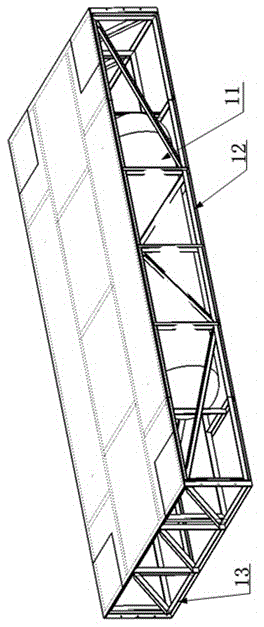

[0025] Example 2: see image 3 — Figure 5, as an improvement of the present invention, the unit body assembly 1 is composed of at least two unit bodies, and the adjacent unit bodies are connected by bolts, and the unit bodies are spliced by including transverse row frames and longitudinal row frames , the unit body is provided with airbags, the number of the horizontal row frames is at least two, the number of the longitudinal row frames is at least two, and the number of the airbags is at least one. The units of the target ship are connected by strong bolts, and the units can be flexibly combined according to actual needs to assemble a target ship of any length and width. During the experiment, even if some units are hit by missiles, The buoyancy of the target ship can still be provided by other units, avoiding the risk of the hull sinking and polluting the water environment. After the target ship is recovered, the damaged unit body can be reused after simple repair and r...

Embodiment 3

[0026] Embodiment 3: see image 3 — Figure 5 As an improvement of the present invention, the spliced target ship also includes a power unit 4 installed at the tail of the target ship hull, and the power unit 4 includes a motor, a propeller and a rudder. The automatic navigation control equipment is connected to the motor through the control cable, and controls the speed of the motor; the motor drives the propeller to rotate through the mechanical transmission device, providing the power required for the target ship to drive; the automatic navigation control equipment drives the rudder to rotate through the hydraulic transmission system, so as to realize Automatic navigation control of the target ship.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com