Composite lining suitable for surrounding rock after-deformation

A composite lining and large-deformation technology, applied in shaft lining, tunnel lining, underground chamber, etc., can solve problems such as inability to adapt to surrounding rock deformation and fault dislocation deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

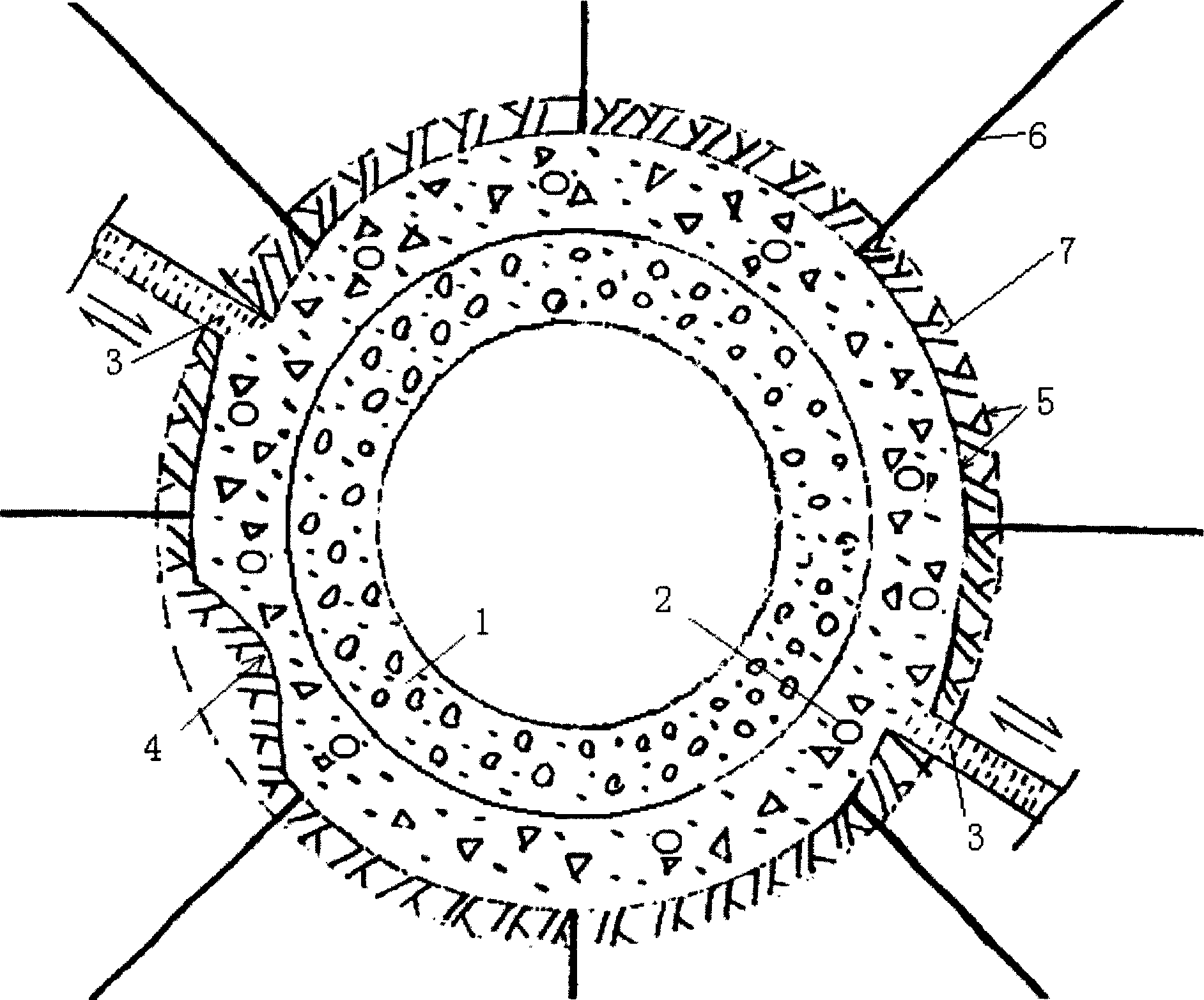

[0013] Such as figure 1 as shown, figure 1 It is a schematic diagram of the composite lining structure of a hydraulic tunnel, and the section of the tunnel is a circle with a diameter of 6.5m. Immediately after the excavation of the tunnel, system bolts 6 are installed, and the surrounding rock 7 is initially supported. space, pour concrete in the formwork to form the inner layer 1. After the inner layer 1 reaches the designed strength, the reserved space is filled with filling materials formulated according to the formula to form the outer layer 2 . The inner layer 1 is a C30 concrete layer with a thickness of 60cm, and the outer layer 2 is a filling layer with a thickness of 50cm. The filling materials are clay, wood, sand, stones and water, and the volume content of clay is 35%.

[0014] Such as figure 1 As shown, when the active fault dislocation deformation 3 occurs, the outer layer 2 undergoes shear flow deformation along with the dislocation deformation of the fault...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com