High-ground-stress large-deformation tunnel release-resistance combined primary support system and construction method

A technology of initial support and high ground stress, applied in tunnels, tunnel linings, underground chambers, etc., can solve the problems of large deformation rate, difficult engineering construction, casualties, etc., and achieve the effects of low cost, convenient construction and fast work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in detail below in conjunction with the embodiments, so that those skilled in the art can implement it with reference to the description.

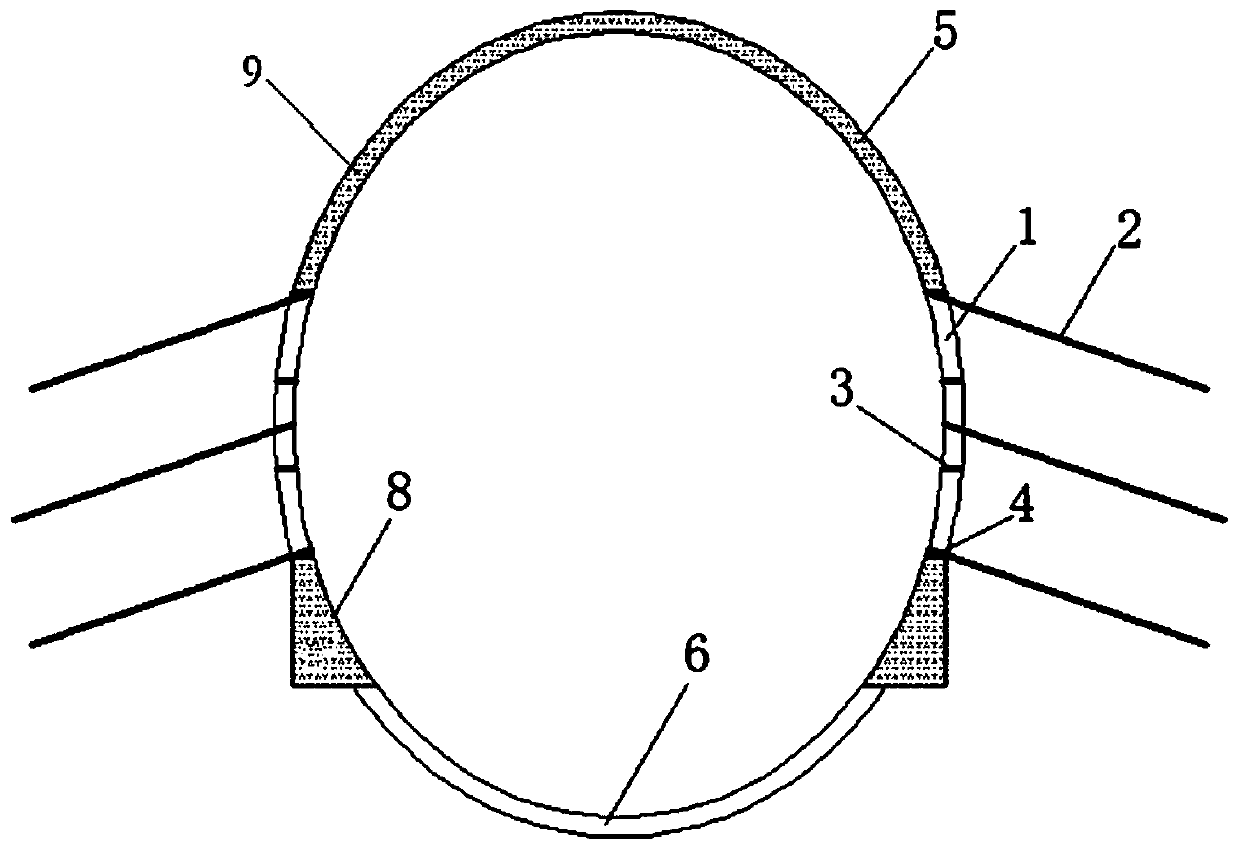

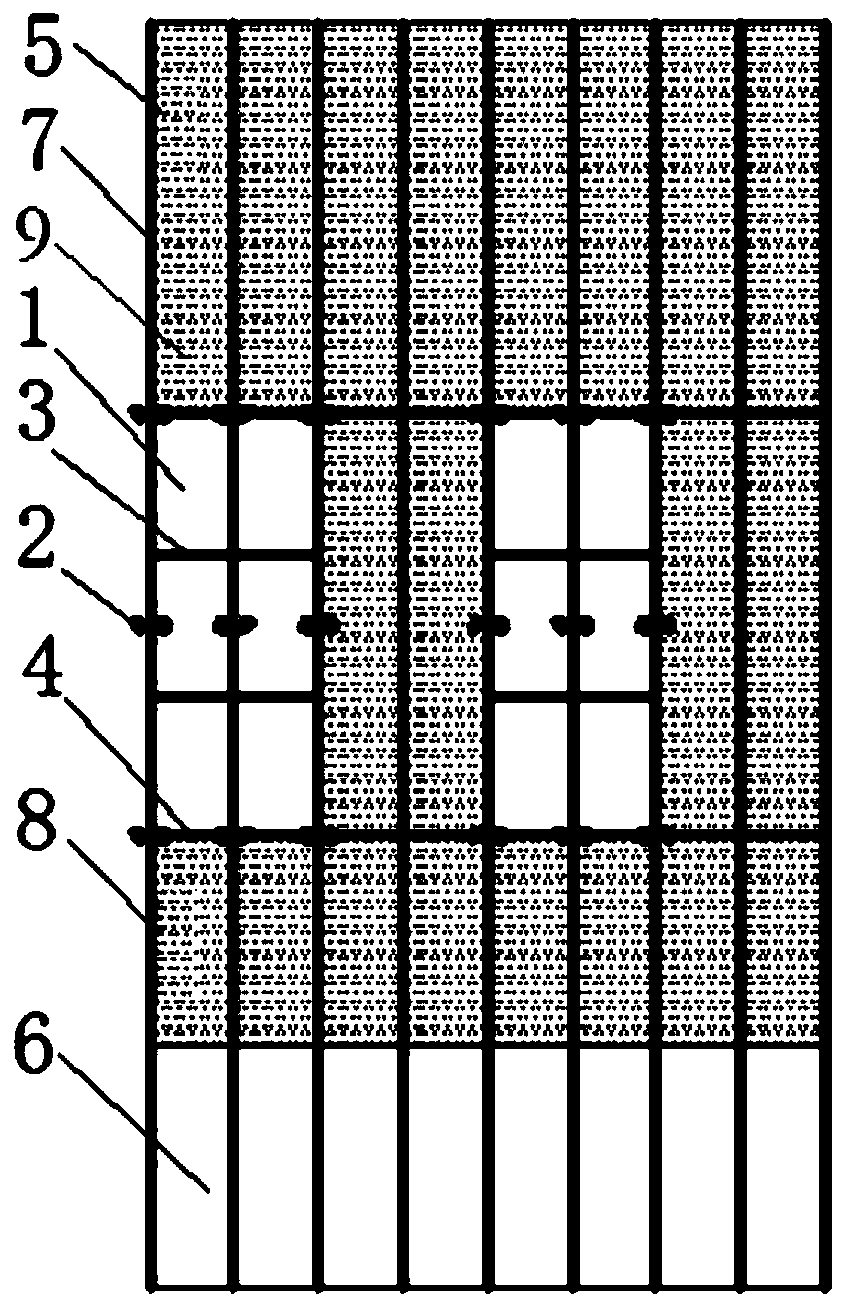

[0029] Such as Figure 1-2 As shown, the present invention provides a primary support system combining release and resistance for high ground stress and large deformation tunnels, including:

[0030] The main body of the primary support is the steel arch 7 and the anchor-mesh-spraying joint support system matched with the steel arch 7, wherein, the primary support main body is provided with a plurality of stress release windows 1, which are located at each side of the primary support main body A plurality of stress relief windows 1 on the side are arranged at intervals along the longitudinal direction of the tunnel.

[0031]In the above technical solutions, for the construction of high ground stress and large deformation tunnels, the essential goal of large deformation control is "no ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com