Hoisting platform special for hoisting and mounting assembled concrete building component and application method of hoisting platform

A technology for concrete buildings and lifting platforms, which is applied to building structures, buildings, cranes, etc., can solve the problems of difficult safety guarantee, low degree of automation, and high labor intensity, so as to improve operation safety, high degree of automation, and improve construction efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

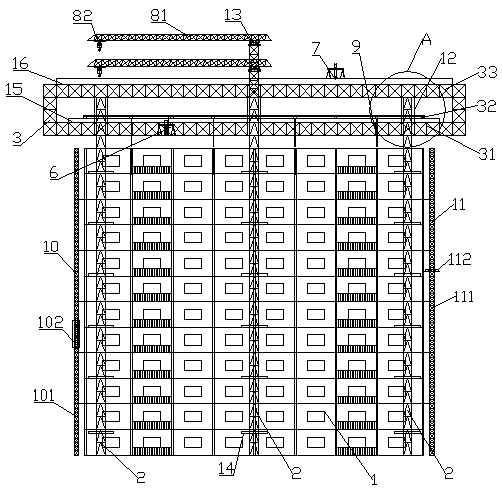

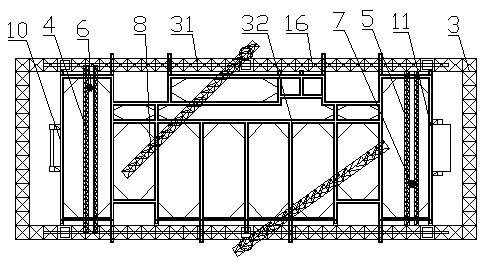

[0024] Embodiment 1: as Figure 1-6 As shown, a special lifting platform for the hoisting and installation of prefabricated concrete building components, including the interconnected synchronous jacking control system, platform stability control system, central control system and hoisting installation system; the synchronous jacking control system has an abnormal inclination angle of the upper platform Functions such as early warning, single-point load monitoring and early warning during multi-point jacking, structural key point stress monitoring and early warning can be effectively fed back to the central control system to ensure the synchronous jacking of each fulcrum of the hoisting installation platform, and the balance and stability of the structural force. The convenience of being in a working state after the hoisting installation platform is in place realizes the safe, reliable and rapid climbing of the hoisting installation platform. The platform stability control syst...

Embodiment 2

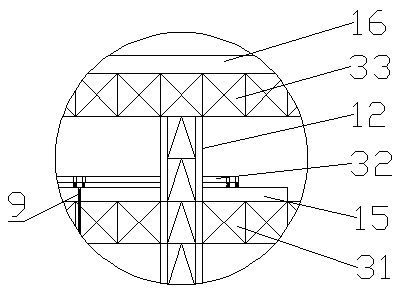

[0026] Embodiment 2: as Figure 1-6 As shown, a special lifting platform for the hoisting and installation of fabricated concrete building components, the upper part of the supporting mast 2 is provided with a platform climbing sleeve 12, and the platform climbing sleeve 12 is fixedly connected with the hoisting installation platform 3; the supporting mast 2 The attached wall 14 is connected with the building body 1, and the hoisting installation platform realizes the increase of the supporting mast 2 by filling the standard section in the platform climbing sleeve 12, and then realizes the automatic raising of the hoisting installation platform 3; in the same way, The mode of removing the standard section from the platform climbing sleeve frame 12 realizes the descent of the supporting mast 2 and the hoisting installation platform 3 . The modular combination design of the special lifting platform realizes the effective splitting of the platform, various combinations and repeat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com