Plastic flexible tube for air exhausting equipment

A technology of plastic hose and air extraction equipment, which is applied in the direction of suction hose, hose, mechanical equipment, etc., can solve the problems of limited flexibility and achieve the effect of flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

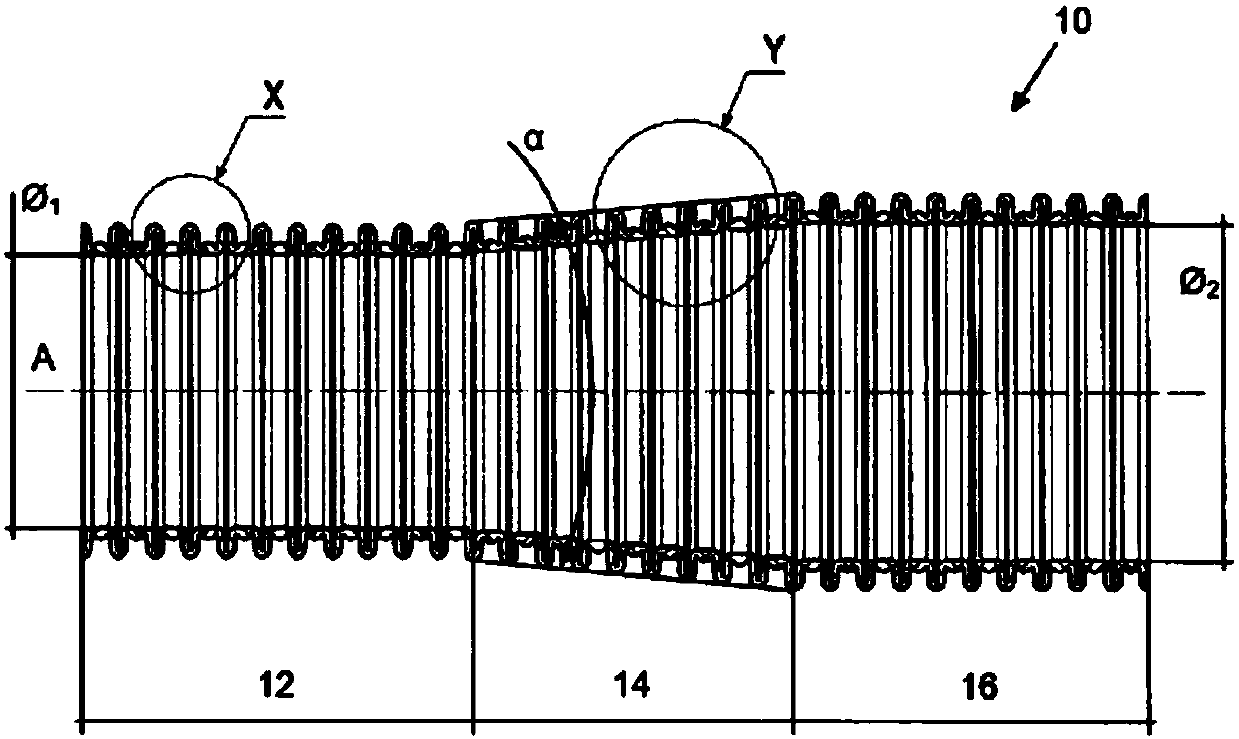

[0026] figure 1 An example of a plastic hose 10 according to the invention is shown, which in this case is part of a vacuum cleaner hose according to the invention, in particular part of an endless hose eg leaving an extrusion device. The endless hose is then divided into individual hose sections having predetermined lengths as required.

[0027] figure 1 The shown vacuum cleaner hose 10 comprises a constant inner diameter Φ 1 A first cylindrical longitudinal section 12, a second cylindrical longitudinal section 14 with a variable inner diameter and a constant inner diameter Φ 2 The third cylindrical longitudinal section 16, wherein the inner diameter Φ of the third longitudinal section 16 2 greater than the inner diameter Φ of the first longitudinal section 12 1 . The inner diameter of the second longitudinal section 14 gradually increases in the extension from the longitudinal section 12 to the longitudinal section 16 , that is, the second longitudinal section 14 is on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com