Large-power burner with air entering from upper portion

A high-power, burner technology, applied in the field of stoves, can solve the problems of poor sealing effect of the burner, gas leakage, poor combustion effect, etc., and achieve good combustion effect, not easy to leak, and good sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

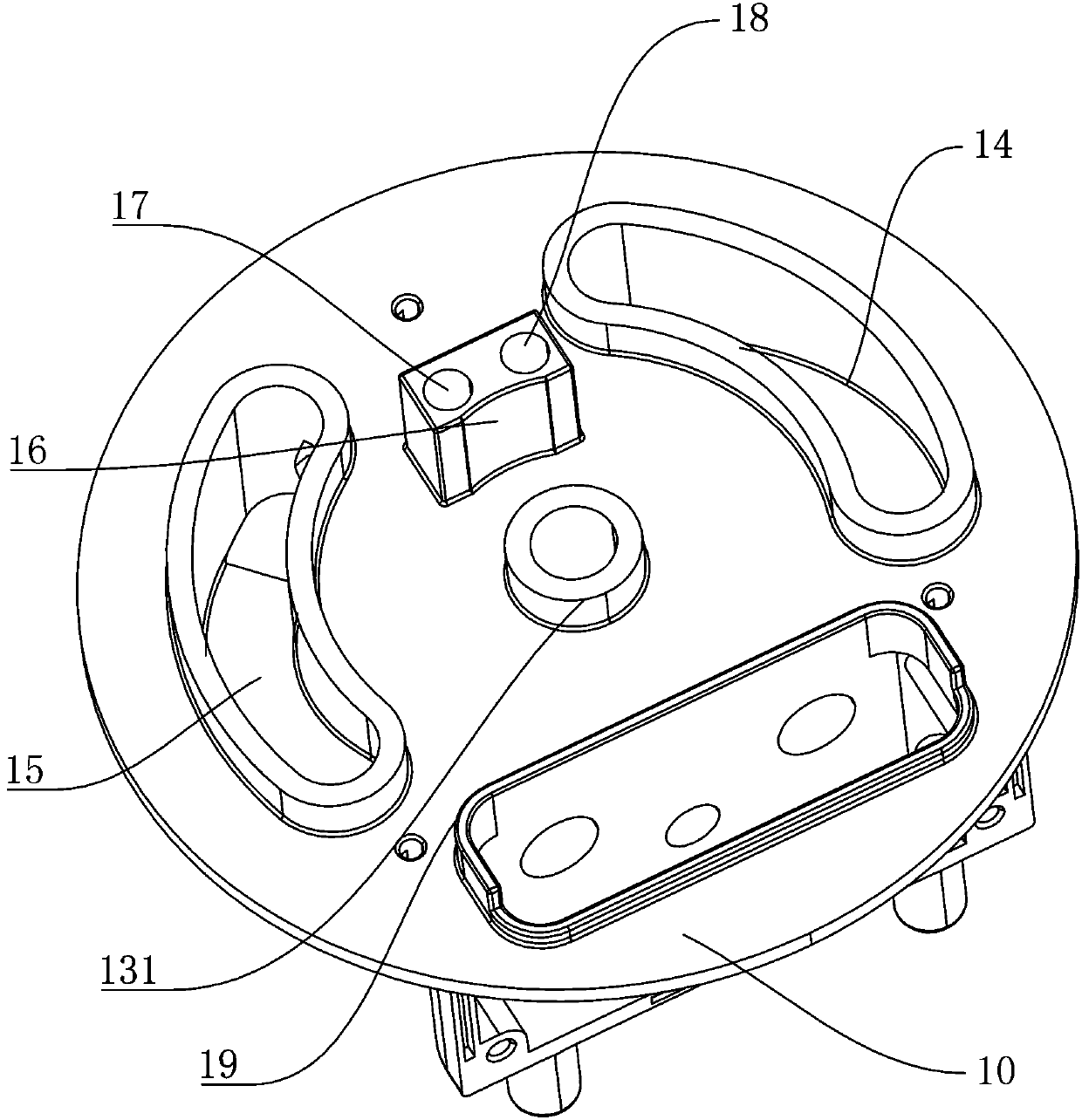

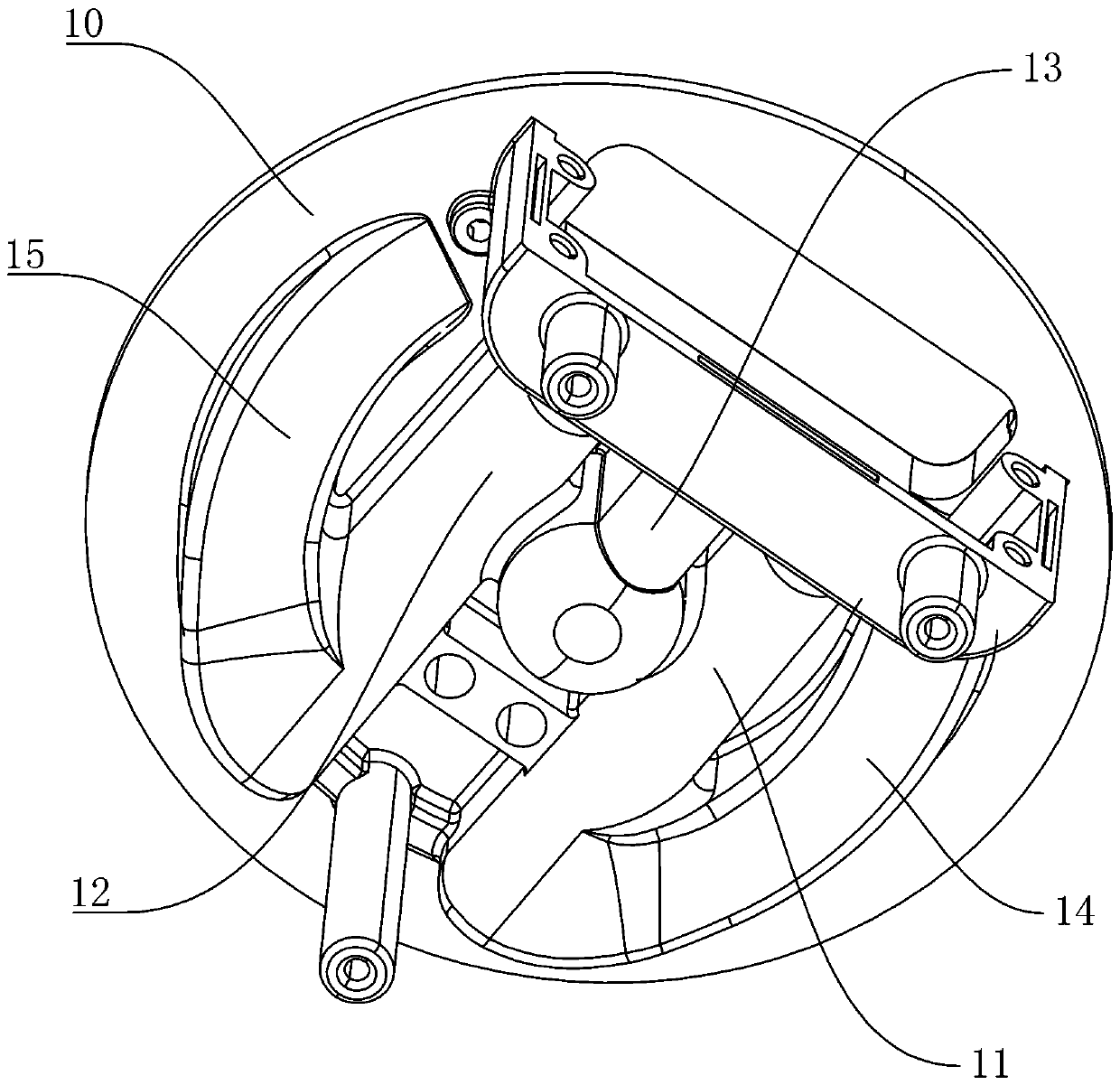

[0025] The present invention is further explained in conjunction with the accompanying drawings.

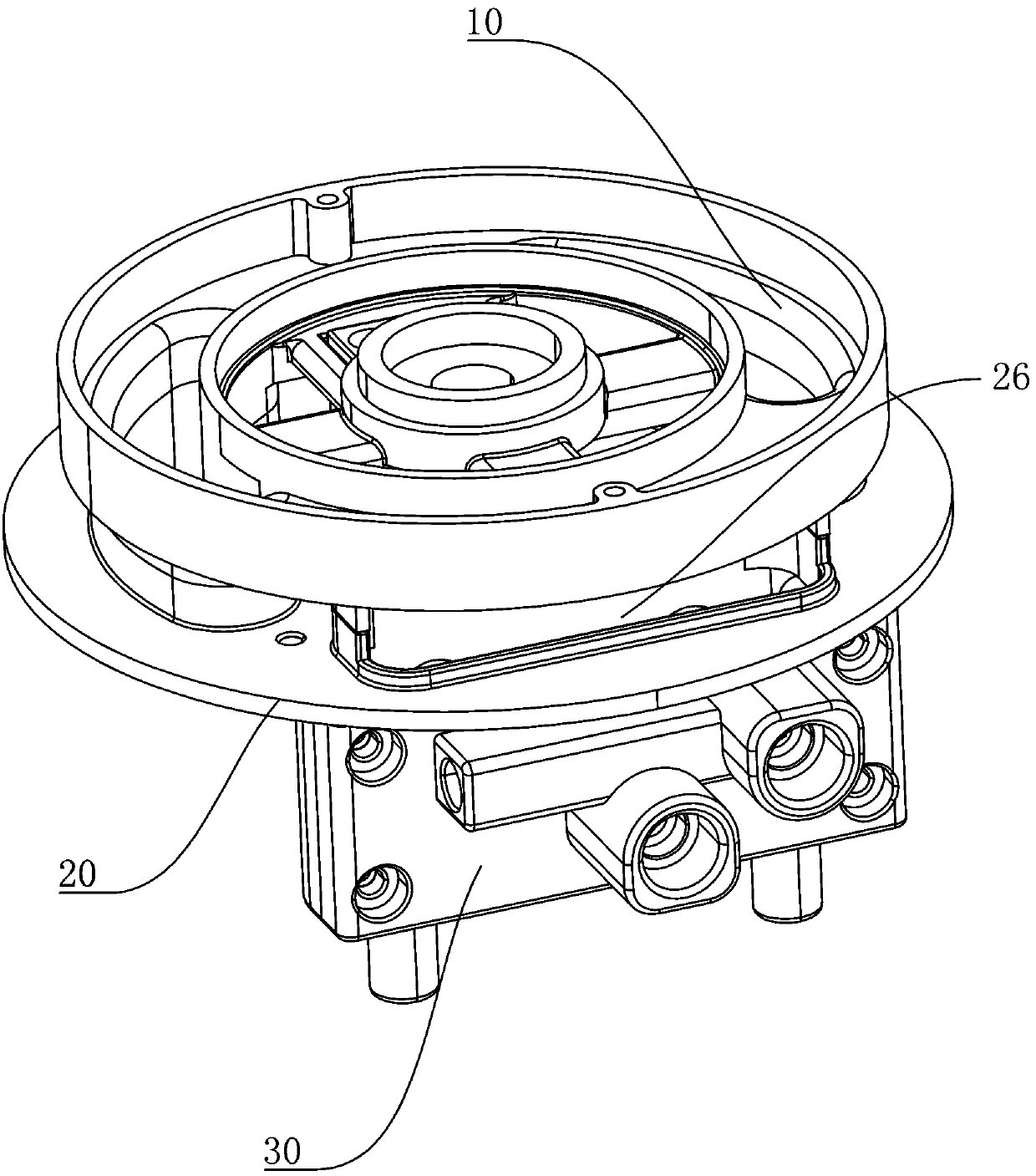

[0026] see Figure 1 to Figure 7 The high-power updraft burner shown includes a base 10 and a bracket 30, and the bracket 30 is fixedly arranged on the base 10. The base 10 and the bracket 30 are respectively cast integrally formed structures, which have good sealing effect and are not easy to leak gas. The base 10 is connected with an air intake head 20, the air intake head 20 is embedded on the base 10 and fixedly connected with the base 10 by screws, the air intake head 20 is provided with a first air intake nozzle 21, a second air intake nozzle 22 and The central air inlet nozzle 23, the air inlet head 20 is also provided with a first gas inlet 24 and a second gas inlet 25, the first gas inlet 24 is directly connected to the first air inlet nozzle 21 and the first gas inlet 24 is connected to the second gas inlet through a connecting pipe. The two air inlet nozzles 22 are in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com