A temperature sensing method based on a liquid-filled hollow-core annular fiber grating

A fiber grating and sensing method technology, applied in the field of sensors, can solve the problems of poor stability of the measurement system of the ring-type optical fiber temperature sensor, and achieve the effects of compact structure, good stability and small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] A high-sensitivity temperature sensing method based on a liquid-filled hollow-core annular fiber grating, comprising the steps of:

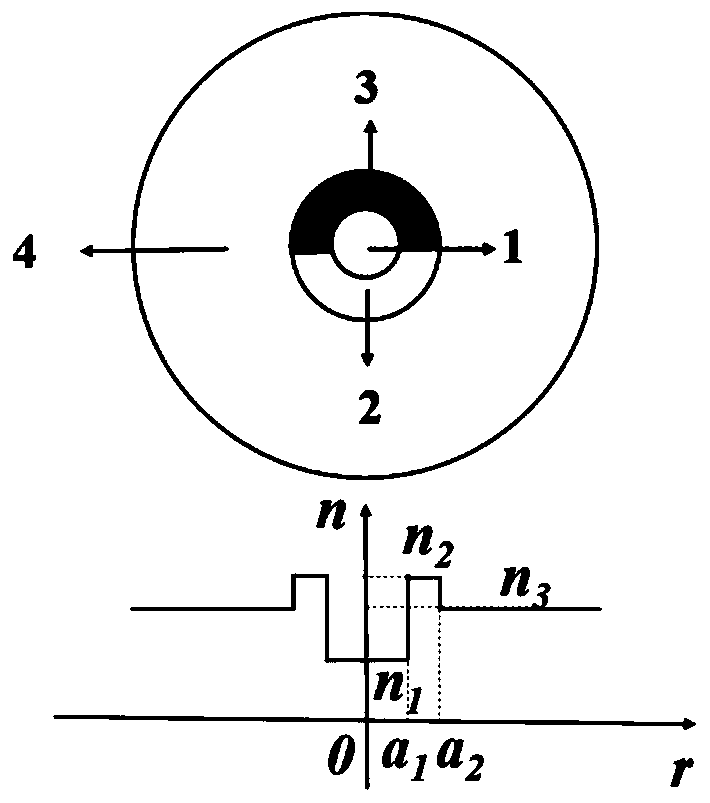

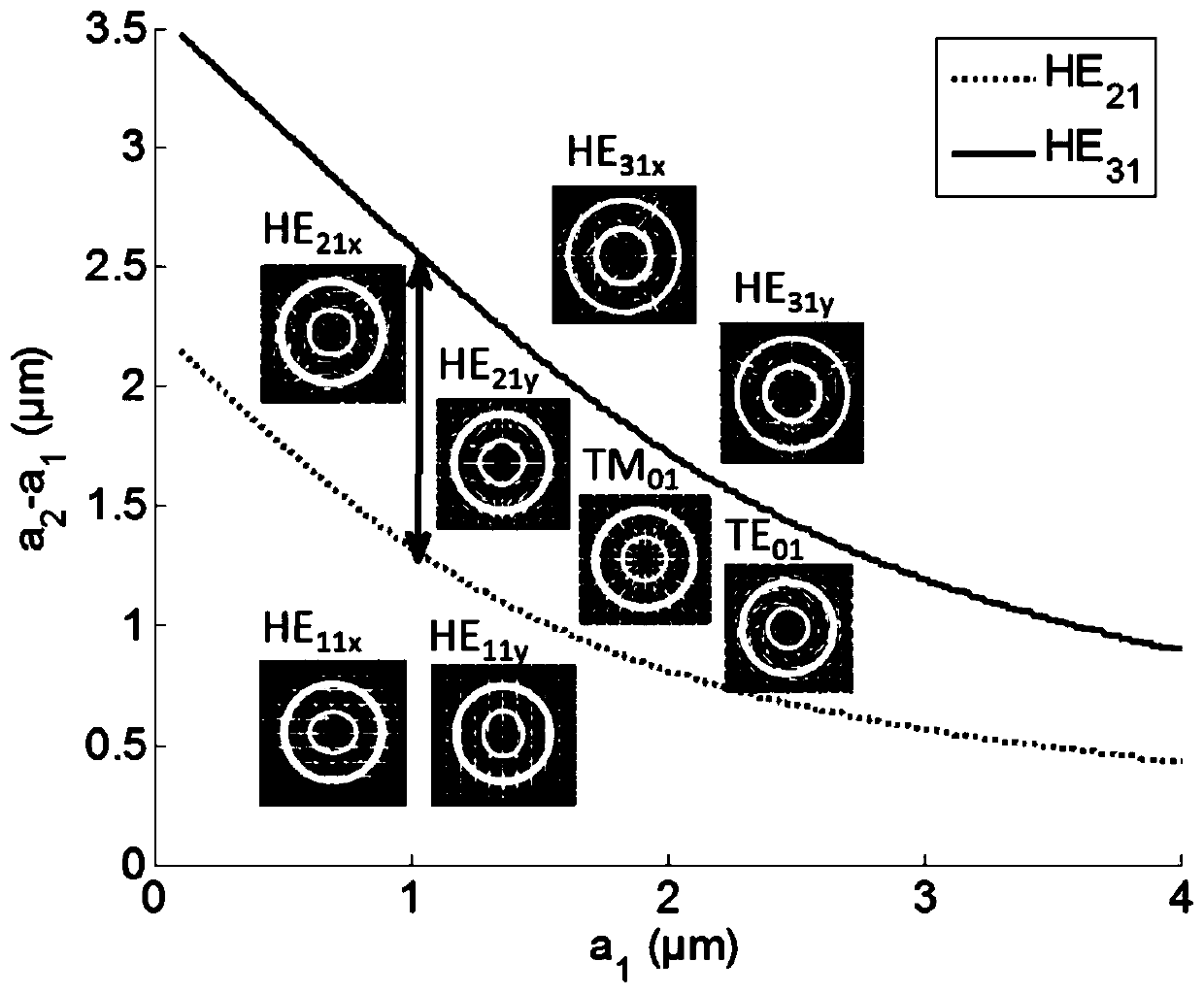

[0036] Step 1: Fabricate a hollow-core ring-shaped optical fiber by chemical vapor deposition and optical fiber drawing equipment. Hollow-core ring fibers have a high-refractive-index ring to transmit light within the high-refractive-index ring. Schematic diagram of the end face structure and refractive index distribution of the grating region of the hollow-core ring fiber figure 1 shown. The inner diameter of the ring core of the hollow core ring fiber a 1 = 1μm, cladding radius a 3 =62.5μm, the high refractive index ring material is Corning SMF-28 core material, and its refractive index n 2 =1.4681, the cladding material is pure silica, its refractive index n 3 =1.444, the relative material refractive index difference between the high refractive index ring and the cladding is 16‰, this material has the advantages of easy acquisition...

Embodiment 2

[0047] A high-sensitivity temperature sensing method based on a liquid-filled hollow-core annular fiber grating, comprising the steps of:

[0048] Step 1, with embodiment 1;

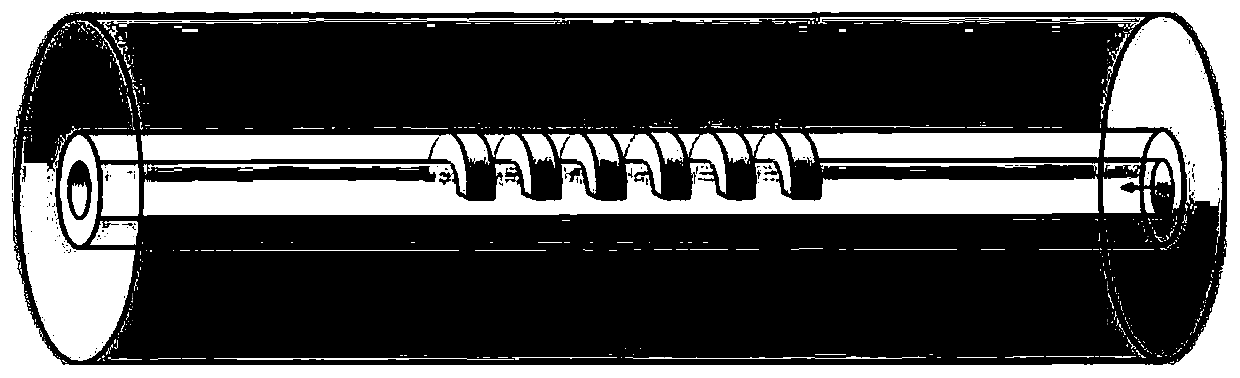

[0049] Step 2: Through unilateral UV exposure of the hollow-core ring-shaped fiber filled with opaque liquid, the periodic refractive index modulation of the upper half-ring is realized, and a hollow-core ring-shaped fiber with an asymmetric grating is made, and the grating period Λ =220μm, the number of grating periods N is 35; the refractive index modulation value Δn=2.8×10 -4 , the corresponding grating length L=0.77cm, the temperature is 25°C, namely n 1 = 1.444, the mode conversion rate is as high as 92.43%. Since the asymmetric fiber grating breaks the circular symmetry of the fiber structure, it can realize the conversion between the angle and non-same-order modes in the ring;

[0050] Step 3: Fill the hollow core of the hollow-core annular fiber grating with a refractive index matching liquid b...

Embodiment 3

[0056] A high-sensitivity temperature sensing method based on a liquid-filled hollow-core annular fiber grating, comprising the steps of:

[0057] Step 1, with embodiment 1;

[0058] Step 2: Through unilateral UV exposure of the hollow-core ring-shaped fiber filled with opaque liquid, the periodic refractive index modulation of the upper half-ring is realized, and a hollow-core ring-shaped fiber with an asymmetric grating is made, and the grating period Λ =235μm, number of grating periods N=45; refractive index modulation value Δn=2.9×10 -4 , the corresponding grating length L=1.058cm, the temperature is 25°C, namely n 1 = 1.444, the mode conversion rate is as high as 99.44%. Since the asymmetric fiber grating breaks the circular symmetry of the fiber structure, it can realize the conversion between the angle and non-same-order modes in the ring;

[0059] Step 3: Fill the hollow core of the hollow-core annular fiber grating with a refractive index matching liquid by capillar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com