Sheep head dehairing system

A technology of sheep head and hair removal machine, which is applied in the field of sheep head hair removal system, which can solve the problems of low work efficiency and insufficient cleanness of hair removal, and achieve the effect of good hair removal effect and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in further detail below in conjunction with accompanying drawing:

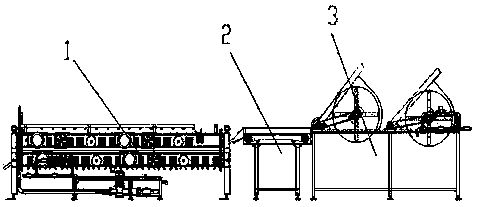

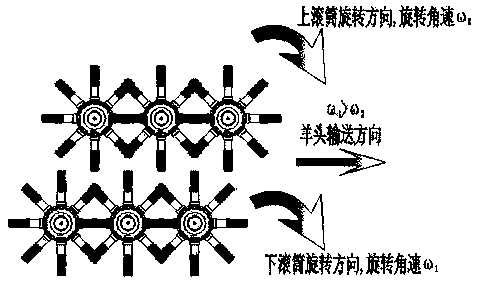

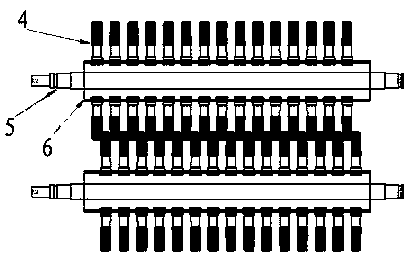

[0014] As shown in the figure is a schematic diagram of the structure of the sheep head hair removal system, including the sheep head hair removal machine 1, the chain conveyor line 2, the scalding machine 3, the rubber rod 4, the screw power shaft 5, the drum 6, the rubber rod 6, and the spray device 7 , Outlet pipe 8, overflow port 9, overturning frame 10, overturning shaft 11, stirring shaft 12, stirring blade 13, main water tank 14 and heating coil 15. The sheep's head is fully stirred in the turning frame with the rotation of the stirring blade. According to the process requirements, it is turned from frame A to frame B at regular intervals, and then turned out of frame B to achieve continuous scalding; the water tank is equipped with a temperature control system , to ensure that the temperature of the entire process environment is suitable and stable; the up...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com