Industrial automatic water filter

A water filter, automatic technology, applied in the direction of filtration and separation, chemical instruments and methods, separation methods, etc., can solve the problems of reducing the practical life of the filter screen, corrosion, inconvenient operation, etc., to increase the area of the sewage outlet, prolong the Long service life, good filtration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to the following description.

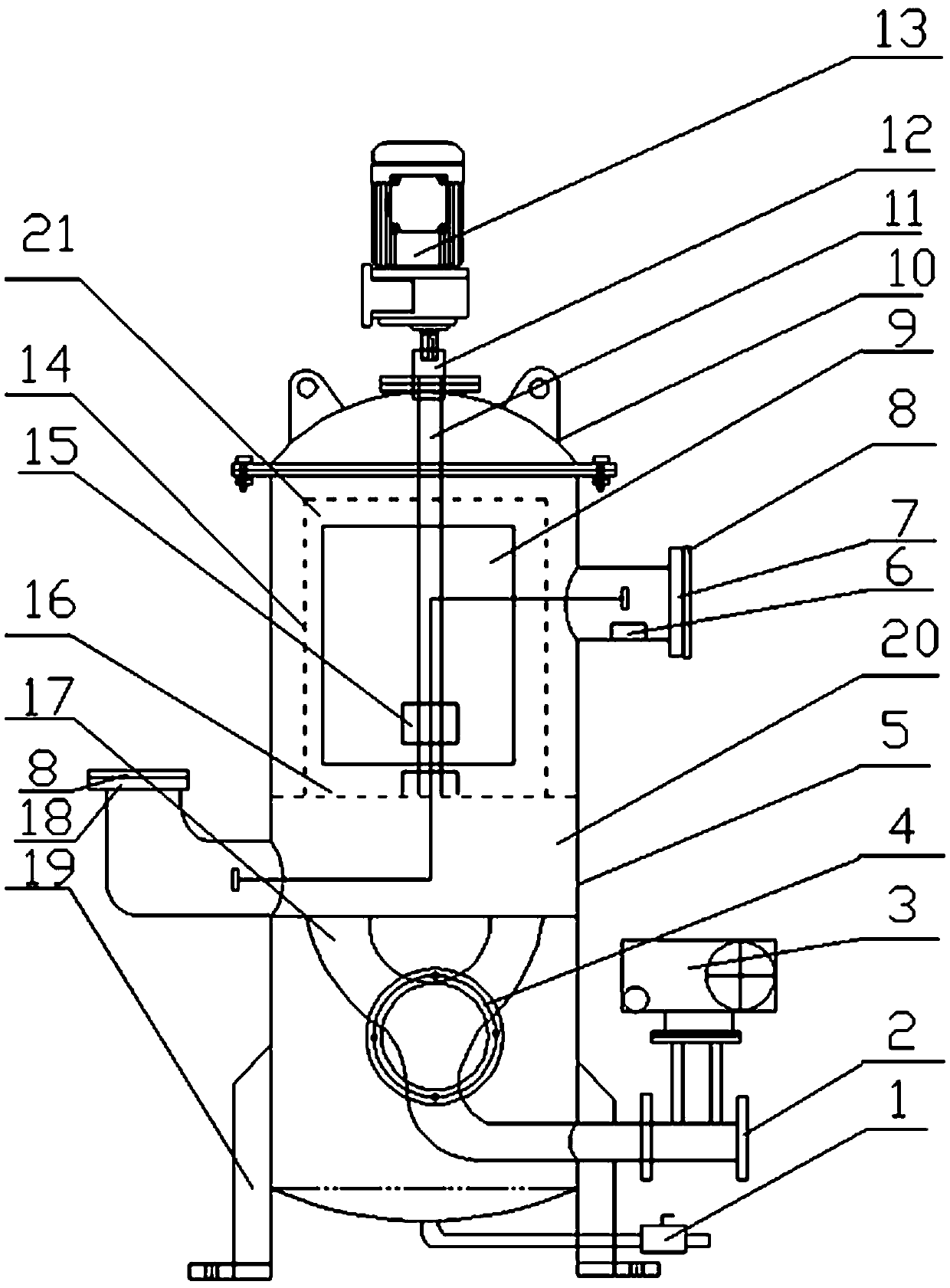

[0015] Such as figure 1 As shown, an industrial automatic water filter includes a cylinder body 5, a PLC electric control box 9, a main shaft 11, and a fine filter screen 14. The bottom of the cylinder body 5 is provided with a drain valve 1, and the cylinder body 5 is provided with an inlet The water outlet 18 and the water outlet 7, the water outlet 7 is on the top, the water inlet 18 is on the bottom, and the PLC electric control box 9 is arranged on the cylinder body 5, and the cylinder body 5 is provided with a cylinder cover 10, and the cylinder cover is equipped with a Geared motor 13, geared motor 13 is connected to main shaft 11 by shaft coupling 12, and fine filter screen 14 is installed on the main shaft 11, and the middle part i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com