A lifting type garbage crushing device

A garbage crushing and lifting technology, which is applied in the direction of grain processing, etc., can solve the problems of difficult removal of garbage, affect work efficiency, increase the burden on workers, etc., and achieve the effect of high work efficiency, simple discharge method and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

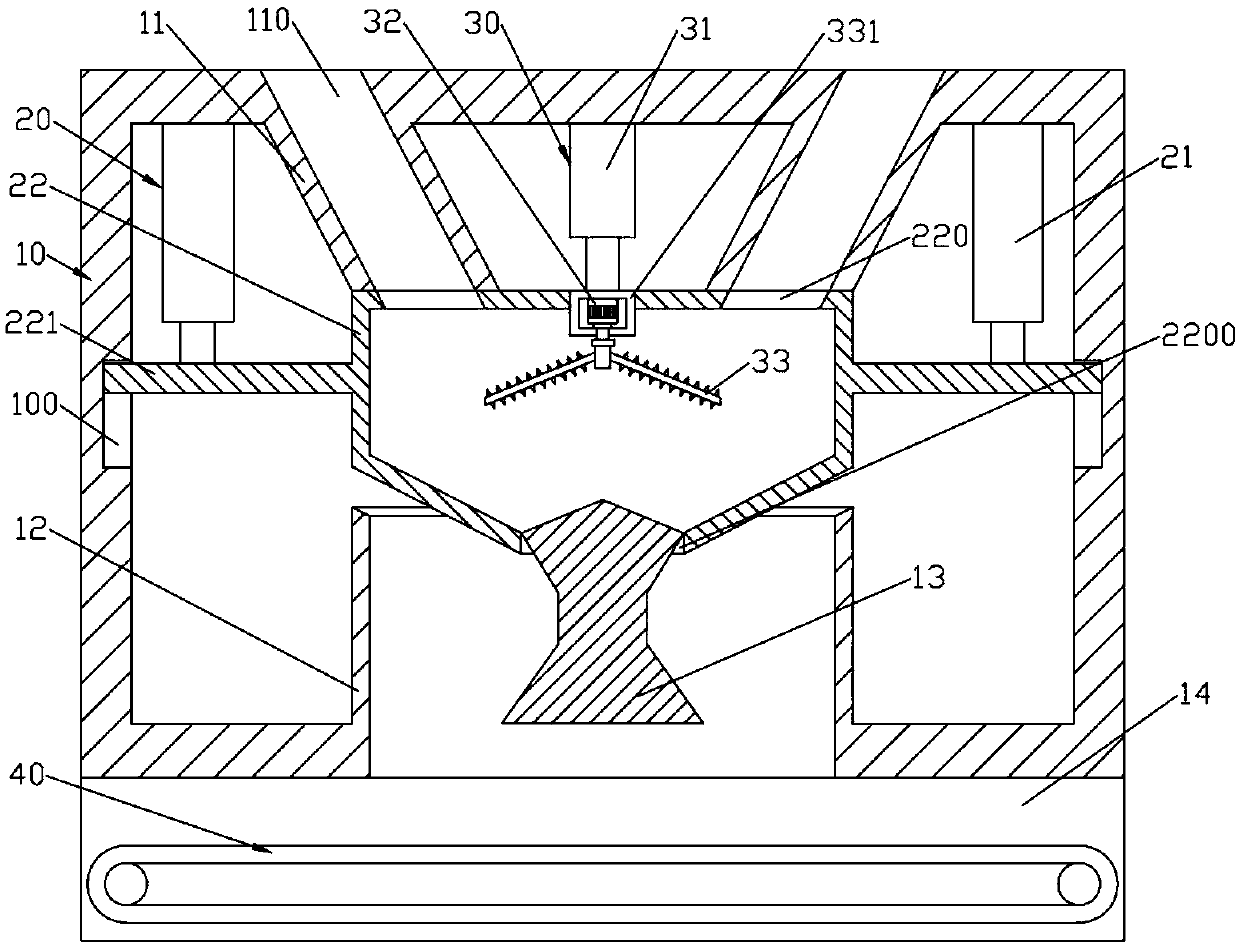

[0013] like figure 1 Shown, a kind of lift-type rubbish pulverizing device comprises support frame 10, lifting feeding and discharging device 20, lifting crushing unit 30 and conveyor belt device 40; A pair of left and right symmetrical feed guide blocks 11 are formed on the upper side wall; feed guide blocks 11 are formed with feed guide holes 110 that incline downward and penetrate up and down; the lifting and discharging device 20 includes a lifting storage box that is set up and down 22; the lifting storage box 22 is a cuboid with a rectangular vacant cavity formed inside; a pair of connecting guide holes 220 cooperating with the feeding guide hole 110 are formed on the upper side wall of the lifting storage box 22; the lifting and crushing unit 30 includes a rotating device The crushing head 33; the crushing head 33 is lifted and arranged in the lifting storage box 22; the blanking frame 12 with a square frame is formed on the lower side wall of the support frame 10; the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com