Bending and shaping structure for slide block of continuous punching die

A stamping die and slider technology, applied in the field of stamping dies, can solve the problems of die damage, waste of manpower, increase of secondary shaping process, etc., to achieve the effect of improving forming accuracy, increasing service life and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings.

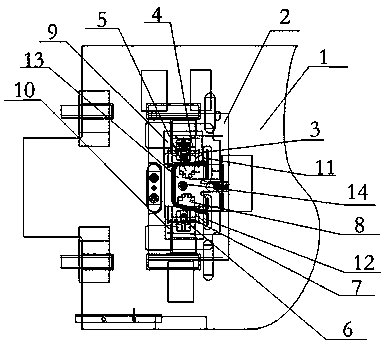

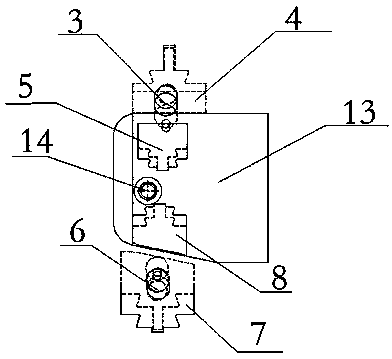

[0017] Such as Figure 1~2 As shown, a continuous stamping die slider bending shaping structure includes a lower die base 1, a lower template 2, a first nitrogen spring 3, a second nitrogen spring 6, a first slider 4, a second slider 5, a second Three sliders 7, the fourth slider 8 and the shaping block 13, the upper end of the lower mold base 1 is provided with the lower template 2, the lower template 2 is provided with the shaping block 13, and the shaping block 13 side is provided with the first slider 4 and the second Two slide blocks 5, the other side of the shaping block 13 is provided with a third slide block 7 and a fourth slide block 8, the first slide block 4 and the second slide block 5 cooperate with the first nitrogen gas spring 3 installed on one side, The third slide block 7 and the fourth slide block 8 cooperate with the second nitrogen gas spring 6 in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com