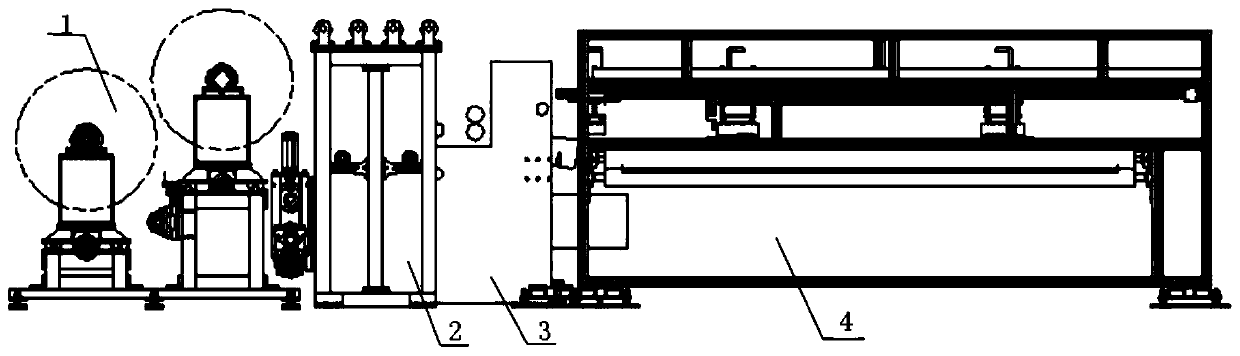

Automatic material distributing equipment and process of one-way prepreg tape

A one-way prepreg belt and automatic cloth technology, applied in the field of material compounding, can solve the problems of no configuration of drive mechanism, operator boredom, high labor cost, etc., and achieve the effect of reliable system operation, avoiding constant tension and eliminating influence.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

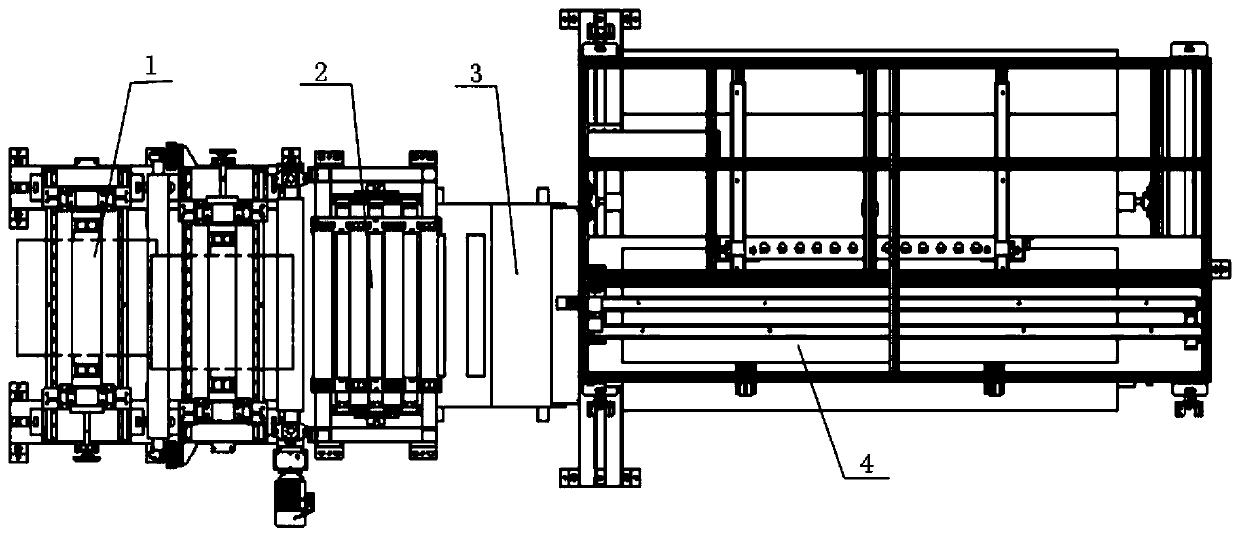

Method used

Image

Examples

Embodiment approach

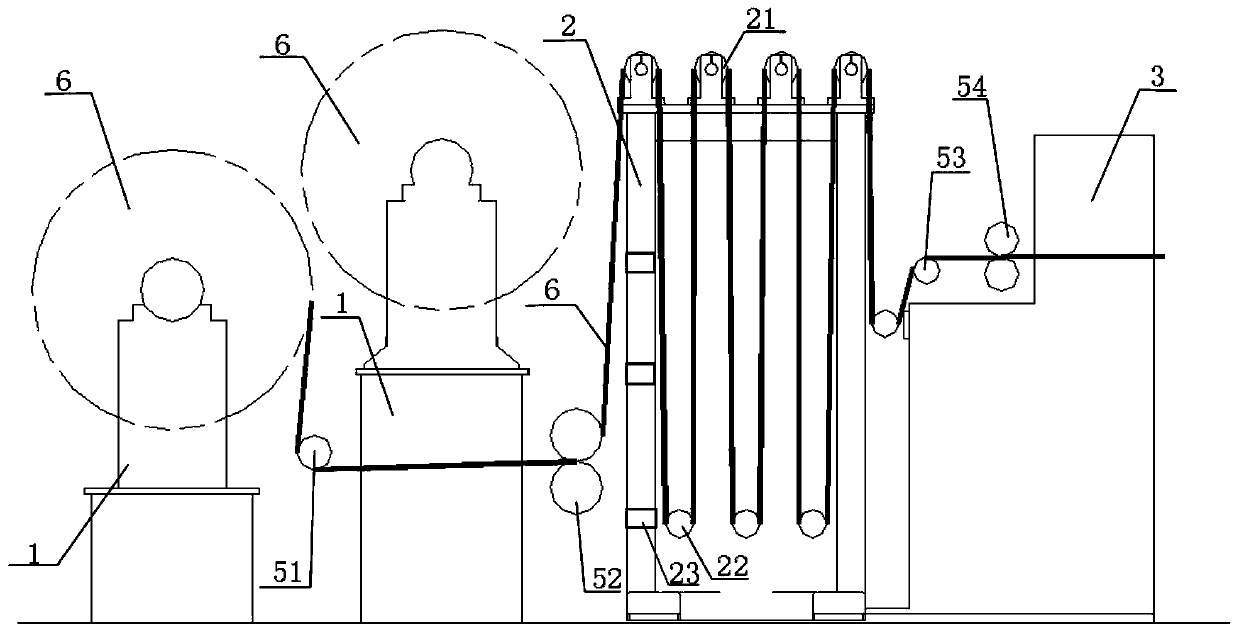

[0055] 1) After the unwinding rack releases the Y material 6, the Y material 6 is hauled and conveyed by the front traction roller 51 and the front pair roller 52 (of course, it can also be other conveying devices, as long as it has the traction and conveying capacity, the same below) , Conveyed to the collecting device 2, and with the help of the fixed roller 21 and the moving roller 22 in the collecting device 2 to carry out zigzag and circuitous transmission, so that part of the strip can be stored in the collecting device 2 to prevent feeding when the unwinding rack is replaced Discontinuous, and different detection switches 23 are triggered by the lifting of the movable roller 22, thereby triggering different conveying speeds to maintain a constant tension during the conveying process of the Y material 6;

[0056] 2) The Y material 6 output from the collecting device 2 is conveyed to the cross-cutting machine 3 through the rear traction roller 53 and the rear pair roller 54, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com