Storage system for parts of electric tools

A technology for electric tools and components, which is applied in the field of storage systems for electric tool components, can solve the problems of uneven thickness and increased workload, and achieve the effects of strong versatility, reduced manual labor, and reduced follow-up screening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The following examples can enable those skilled in the art to understand the present invention more comprehensively, but the present invention is not limited to the scope of the described examples.

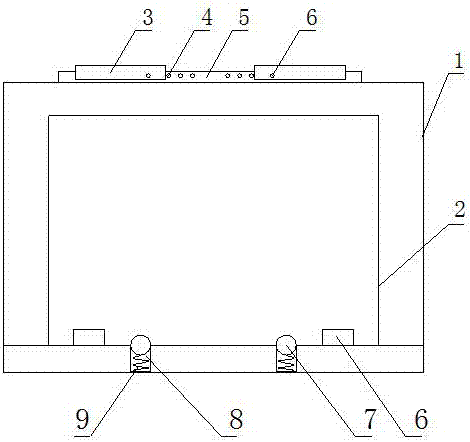

[0016] Such as figure 1 A parts storage system for electric tools is shown, the storage system is used to store drill bits, including

[0017] A storage inner box 2, the storage inner box 2 is a hollow cuboid structure with an open upper end.

[0018] A storage outer box 1, the storage outer box 1 is a hollow cuboid structure, the upper end of the storage outer box 1 has a rectangular through hole for drill bits to pass through, and the side end of the storage outer box 1 has a storage inner box 2 embedded There is a pair of positioning guide rails 6 at the inner bottom of the storage outer box 1, and a positioning groove corresponding to the positioning guide rails 6 is provided at the bottom of the storage inner box 2 at the same time, while the storage outer box 1 is lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com