Energy-saving rapid solid-liquid separation device

A solid-liquid separation and rapid technology, applied in the direction of presses, manufacturing tools, etc., can solve the problems of damage separation efficiency, low manufacturing cost, damage of physical and chemical properties of solid-liquid mixed substances, etc. fast speed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

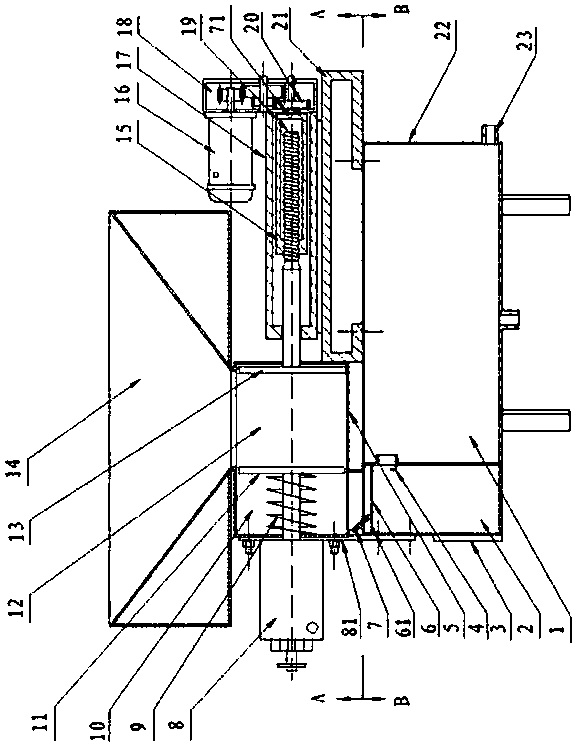

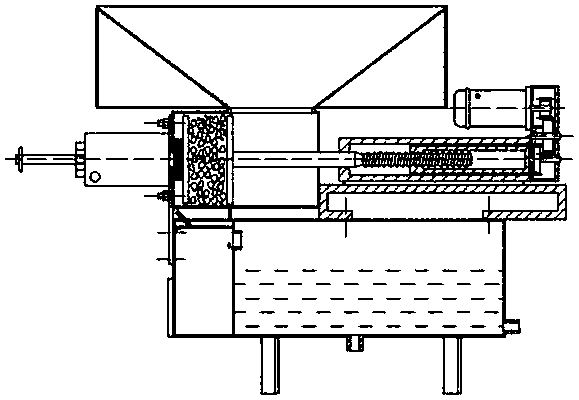

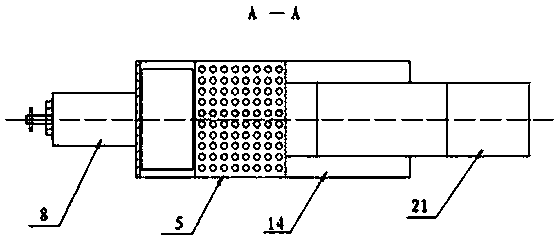

[0024] In order to have a further understanding and understanding of the structural features of the present invention and the achieved effects, a detailed description is provided in conjunction with preferred embodiments and accompanying drawings: as Figure 1 to Figure 6 As shown, an energy-saving rapid solid-liquid separation device includes a rapid extrusion component, an electromagnetic attraction component, a solid-liquid separation chamber, and a box 22 .

[0025] The rapid extrusion assembly includes a motor 16, a reduction box 18, a guide rail cylinder 17, a spiral track assembly 15, a driven gear 20, a copper sleeve 71 of a reduction box, and a screw extrusion plate 13; the electromagnetic attraction assembly includes an electromagnet 8. Electromagnet spring 9, solid material pressing plate 11, the solid-liquid separation chamber includes a solid material chamber part 10 and a solid-liquid separation chamber part 12, and the box body 22 includes a solid material collec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com