Sand unloading device

A sand bucket and mounting plate technology, applied in the field of casting, can solve problems such as occasional occurrence, damaged tape, splitting, etc., and achieve the effect of reducing maintenance workload and prolonging life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

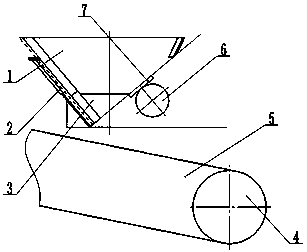

[0012] Examples, see attached figure 1 , a sand unloading device, including a sand bucket 1, a mounting plate 2, a trough 3, a pulley 4, a conveyor belt 5, a driving motor 6 and a motor seat 7, wherein the sand bucket 1 is welded by section steel , the lower part of the sand bucket 1 adopts an angle of 40°, the left side of the sand bucket 1 is provided with an outlet, the installation plate 2 is fixedly installed on the left side of the sand bucket 1 and can slide along the sand bucket 1, and the hopper 3 is fixedly installed on the At the outlet of the sand bucket 1, the drive motor 6 is fixedly installed on the motor base 7, the motor base 7 is fixedly installed on the right end of the sand bucket 1, and the two ends of the conveyor belt 5 are installed on the pulley 4 and are located in the sand bucket. 1 directly below.

[0013] Preferably, the mounting plate 2 is automatically adjusted by a cylinder.

[0014] Preferably, the vibration force of the drive motor 6 is adju...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com