Cutting device for high-strength glass

A cutting device and high-strength technology, applied in glass cutting devices, glass manufacturing equipment, manufacturing tools, etc., can solve the problems of wasting water resources, glass fixing is not firm enough, etc., and achieve the effects of saving energy, improving precision, and ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

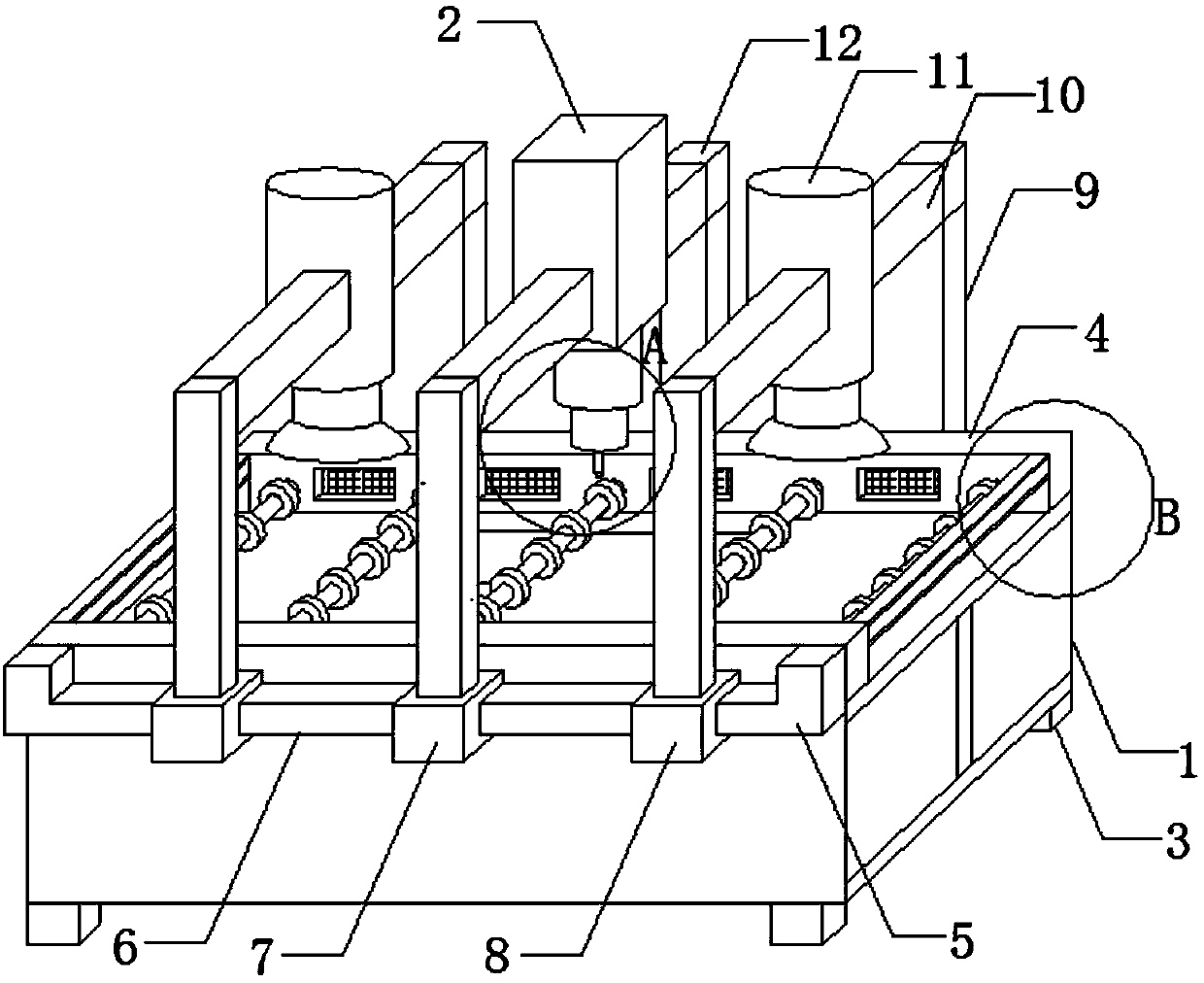

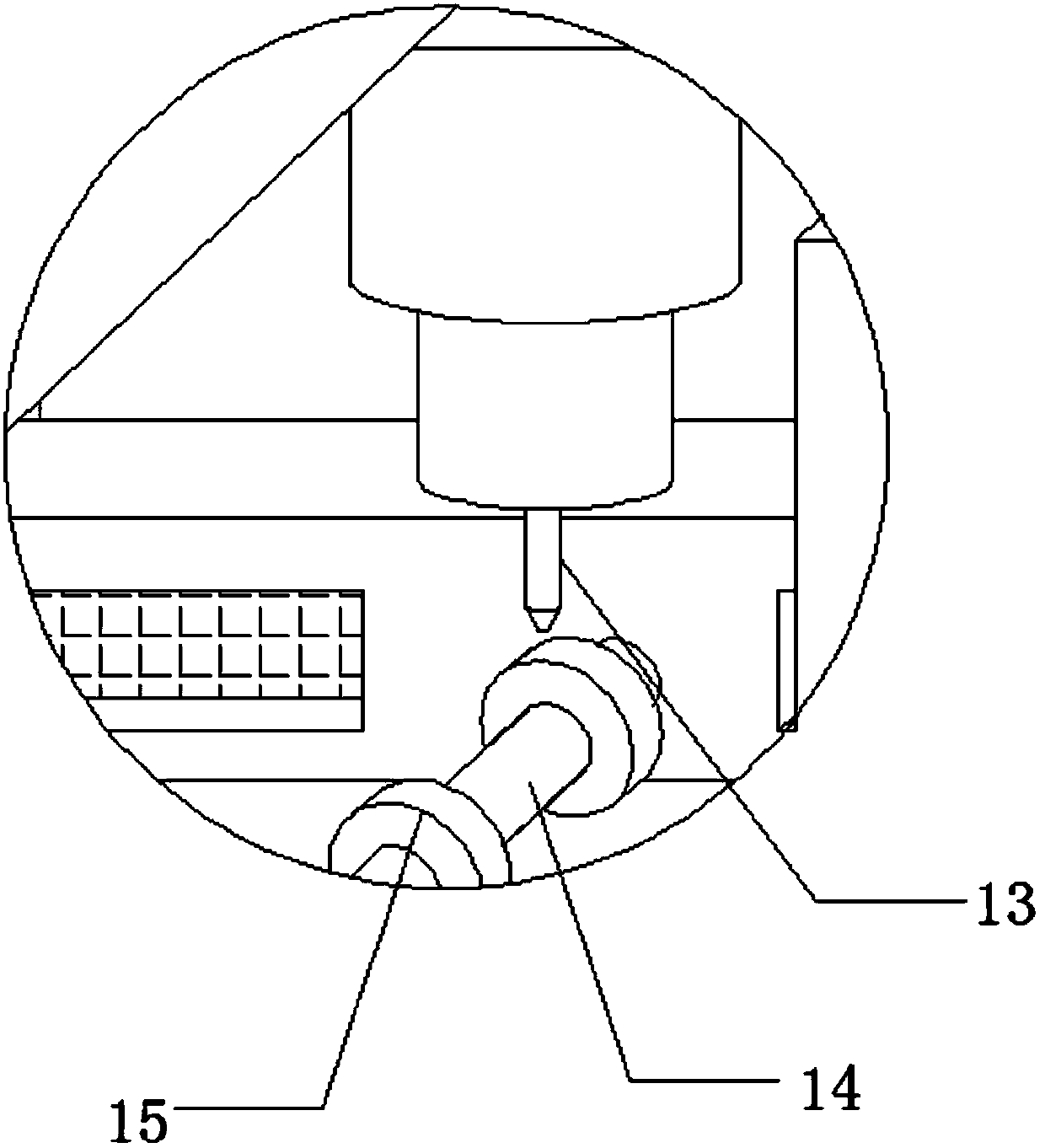

[0024] see Figure 1-5 As shown, a high-strength glass cutting device includes a cabinet 1 and a cutting cabinet 2. The bottom of the cabinet 1 is welded with several legs 3, and the legs 3 are evenly distributed on the four bottom corners of the cabinet 1. Both sides of the top of the cabinet 1 are Weld the baffle plate 4, weld the fixing seat 5 at both ends of the side wall of the baffle plate 4, weld the slide bar 6 between the two fixing seats 5, the middle part of the slide bar 6 engages the first slider 7, and both sides of the first slider 7 are Engage the second slider 8, and the first slider 7 and the two second sliders 8 can slide to adjust the position on the slider 6, and the top of the second slider 8 is welded to the support rod 9,, the support rod 9 The beam 10 is welded on the top, and the middle part of the beam 10 is engaged with the hydraulic pump 11, and the hydraulic pump 11 can drive the hydraulic rod 20 to move up and down. A number of rotating shafts 1...

Embodiment 2

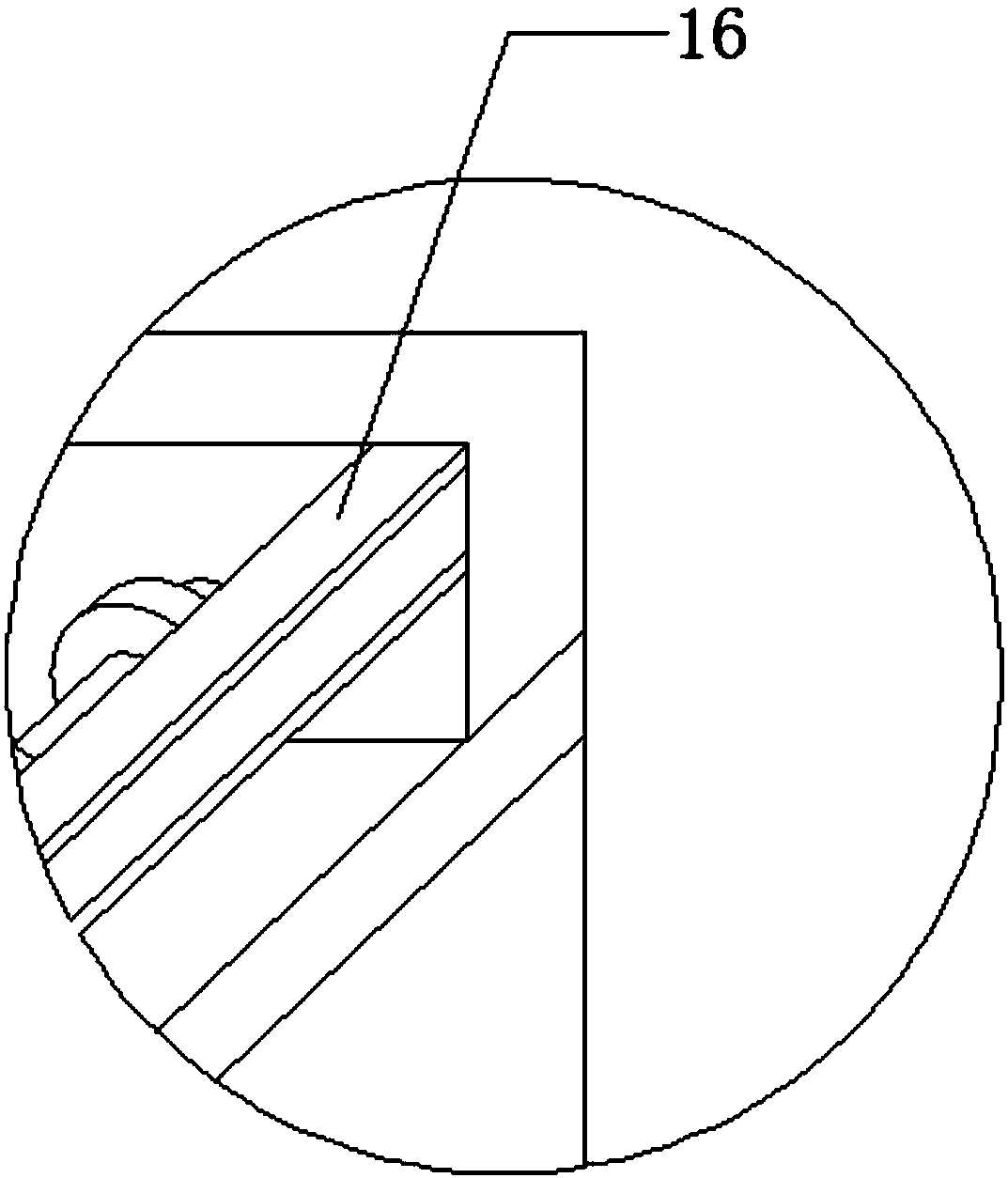

[0026] In addition, please continue to Figure 2-5 As shown, the difference between it and Embodiment 1 is that both the first slider 7 and the second slider 8 are engaged on the slider 6 through the slot 23, and the first slider 7 and the second slider 8 are both connected to the The slide bar 6 is movably connected, so that the first slide block 7 and the second slide block 8 can slide to adjust the position, which is convenient for the cutting machine case 2 to cut different positions, and can absorb and fix the glass by the suction cup 21 during the cutting process, ensuring The stability of the glass, the cutting box 2 is set in the middle of the bracket 12, and the cutting box 2 is set directly above the cabinet 1, so that the cutting box 2 can just cut the glass placed on the top of the cabinet 1, and the fan 18 is set through the fixed frame 19 Inside the baffle plate 4, the fan 18 is electrically connected to the external power supply through wires, so that the fan 18...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com