Oil injection and air exhaust system of electro-hydraulic actuating mechanism

An electro-hydraulic actuator and exhaust system technology, which is used in fluid pressure actuation system components, mechanical equipment, servo meter circuits, etc. To achieve the effect of resisting oil pollution, strong anti-pollution ability and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

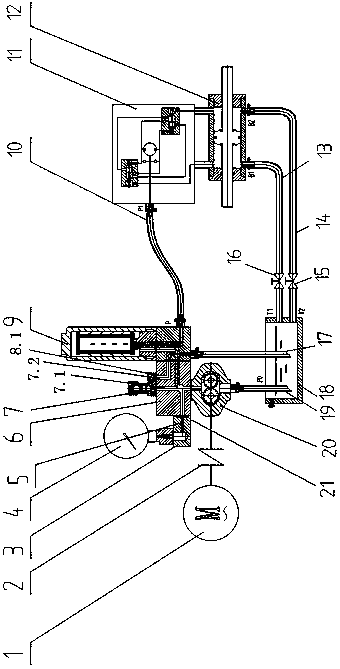

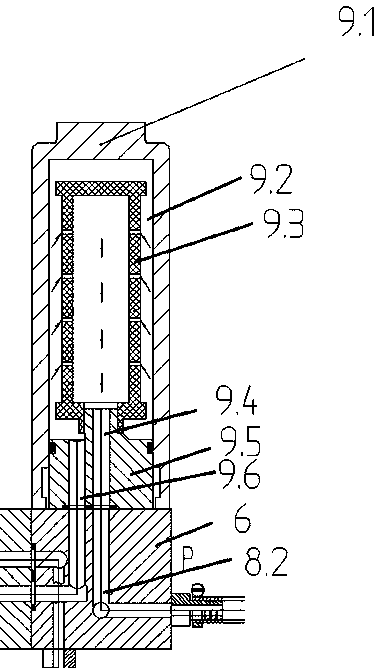

[0012] see figure 1 , which includes an electro-hydraulic actuator consisting of a drive cylinder 12 and an integrated electro-hydraulic actuator 11. The drive cylinder 12 has two left and right oil chambers, the left oil chamber is provided with a left oil discharge port B1, and the right oil chamber is provided with a right row Oil exhaust port B2; oil port P0 of oil tank 18, gear pump 20, hydraulic oil filter 9, oil injection port P1 of integrated electro-hydraulic actuator, oil exhaust port B1, B2 of the driving cylinder and oil return of the oil tank Ports T1 and T2 form a closed-loop oil circuit; the oil circuit between the oil port of the oil tank and the gear pump is inserted into the oil tank by the oil suction pipe 19 of the gear pump; the oil circuit between the gear pump and the hydraulic oil filter is the main oil circuit block The first section of the main oil passage 8.1 formed in 6, the hydraulic oil filter and the gear pump are respectively installed on the to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com