Food air drying system

A food and drying room technology, which is applied in drying, drying machines, drying rooms/containers, etc., can solve the problems of poultry and fish food that are prone to rot and deterioration, restrictions on the production of air-dried and dehydrated food, and fast virus reproduction. , to achieve the effect of reducing bacterial pollution, ensuring quality and fast dehydration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below with reference to the accompanying drawings and specific embodiments, but it is not intended to limit the present invention.

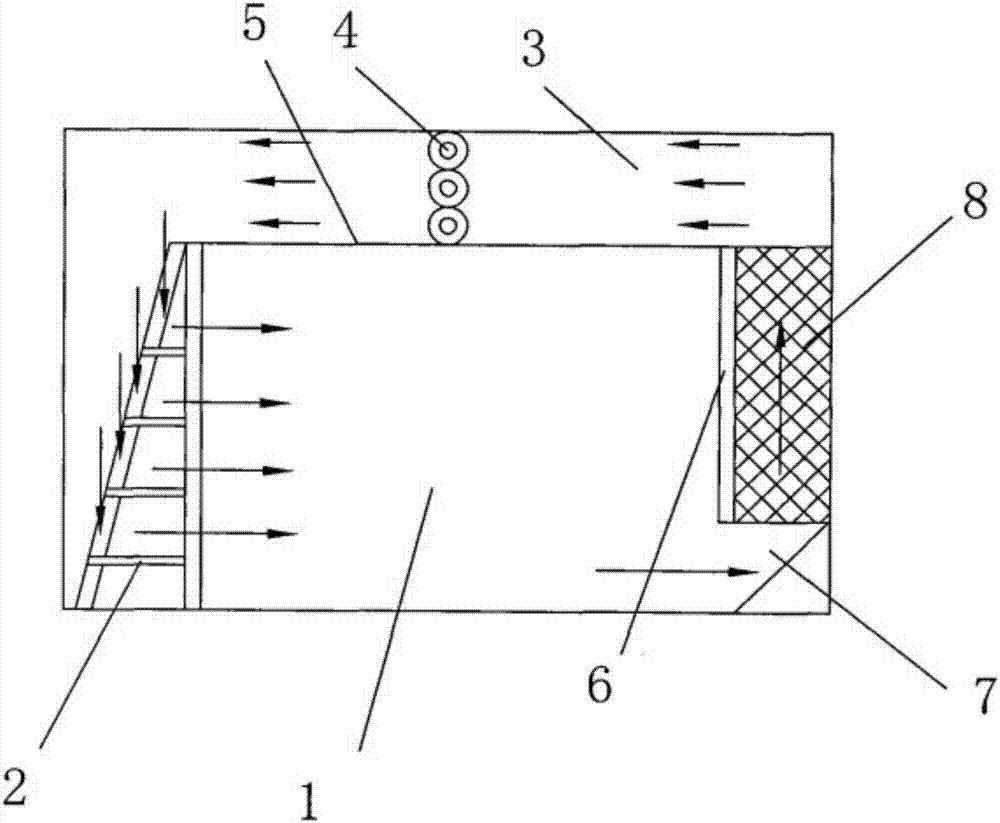

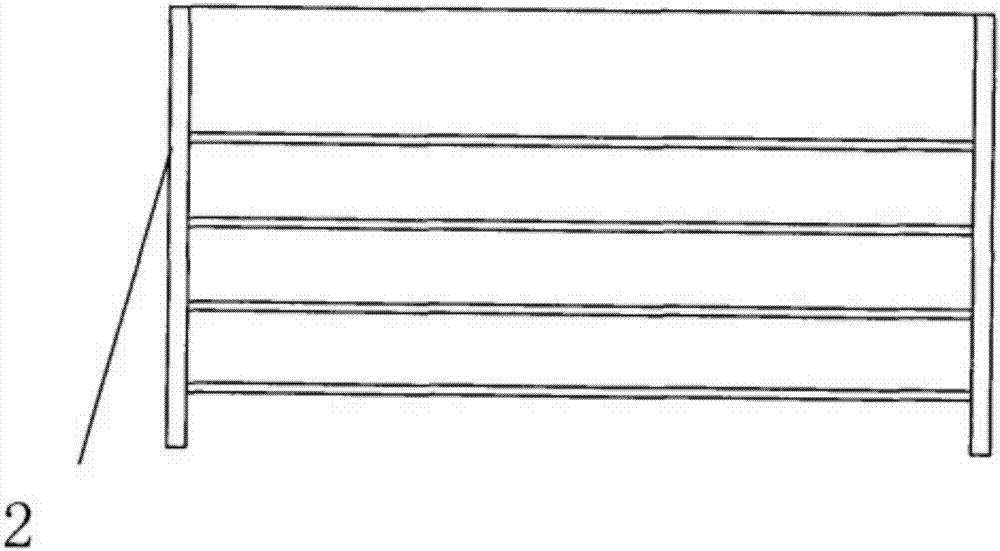

[0018] like Figure 1 to Figure 3 As shown, a food air-drying system includes a drying chamber 1 and a drying rack (not shown in the figure), the drying rack is used for placing livestock or fish food, and the drying rack can be pushed into or pushed out of the drying chamber 1,

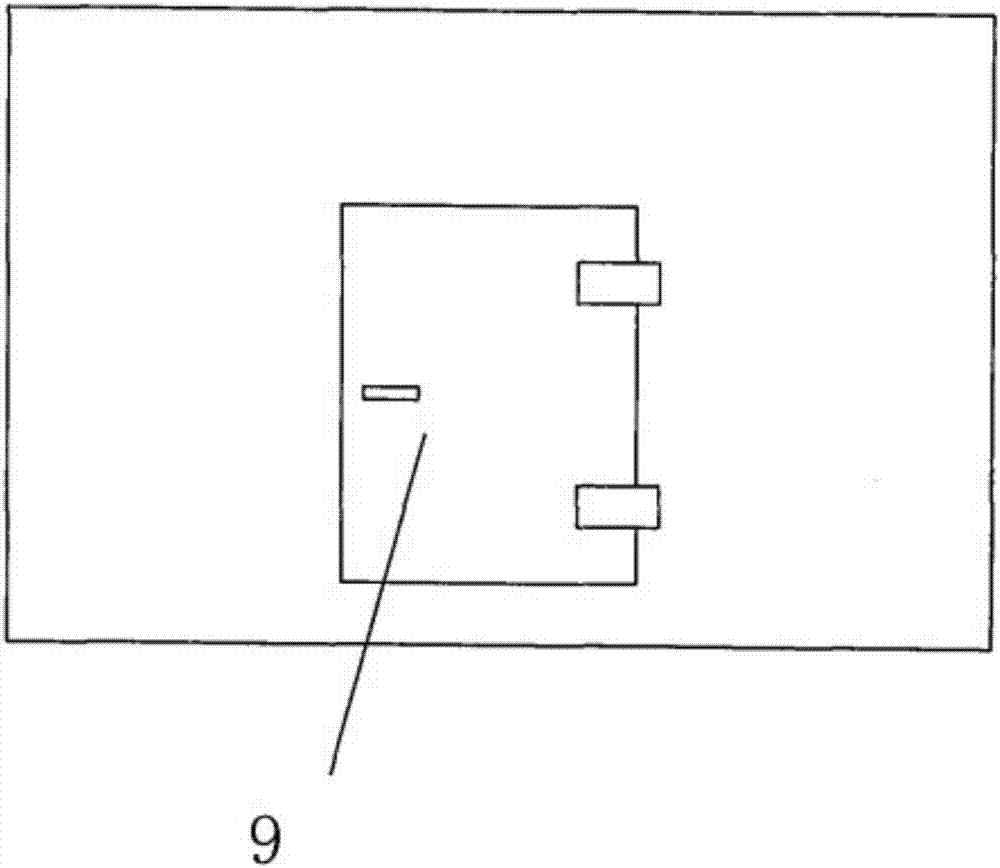

[0019] It also includes a fan room 3, 3 fans 4, a shelf 5, an air inlet structure 2, a partition 6, an air outlet channel 7, a cooling plate 8 and a door 9; The walls are fixedly connected; the fan chamber 3 is arranged above the shelf 5, the air inlet structure 2, the drying chamber 1 and the cooling plate 8 are respectively arranged below the shelf 5 from left to right, and the left side of the air inlet structure 2 and The left part of the fan chamber 3 is communicated with, and the right side of the air inlet s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com