A kind of urban sewage advanced treatment system

A technology for advanced treatment and urban sewage, which is applied in water/sewage multi-stage treatment, biological water/sewage treatment, water/sludge/sewage treatment, etc. Solve problems such as secondary pollution, achieve simple and feasible workflow, save landfill land, and avoid secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings.

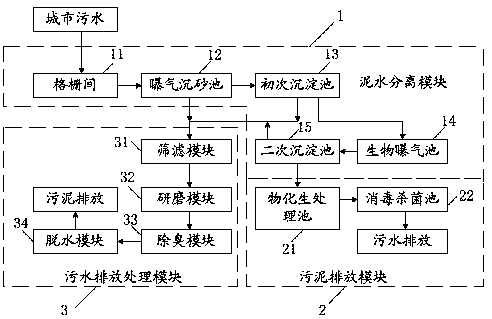

[0035] Such as figure 2As shown, the present invention provides a kind of urban sewage advanced treatment system, comprising:

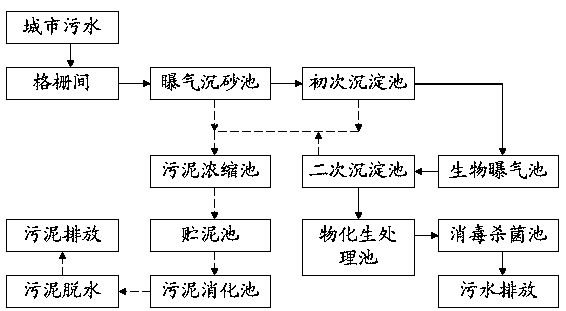

[0036] Sludge-water separation module 1, through grille removal, sand settling, primary sedimentation, biological treatment and secondary sedimentation to separate sewage from sludge, the treated sewage is discharged to sewage discharge treatment module 2, and sludge is sent to sludge Emission treatment module 3;

[0037] Sewage discharge treatment module 2, which uses physical, chemical or biological methods to treat sewage, and discharges after reaching the discharge index after disinfection and sterilization;

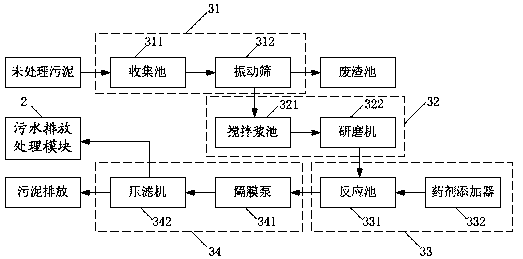

[0038] The sludge discharge treatment module 3 uses grinding for physical wall breaking, chemical reagents for chemical wal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com