Contact finger assembly

A technology of contact fingers and components, which is applied in the direction of electrical components, high-voltage air circuit breakers, electric switches, etc., can solve the problems of high connection clearance requirements, inability to guarantee load consistency, and high production precision requirements, so as to ensure load consistency , reliable contact and good dynamic stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

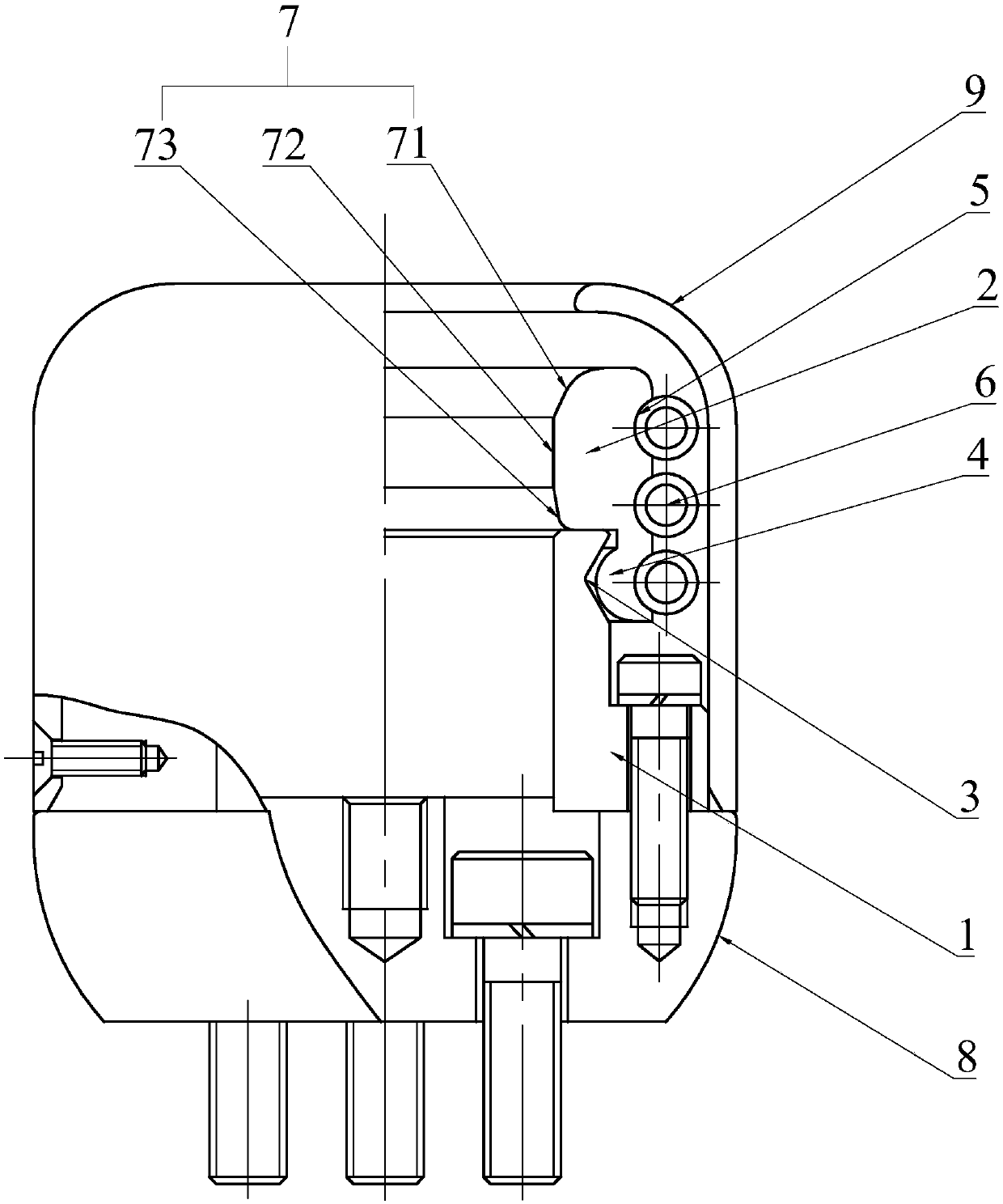

[0018] see figure 1 As shown, the contact finger 2 assembly of the present invention includes a contact finger 2 seat 1 and several contact fingers 2, the contact finger 2 seat 1 is tubular and the outer wall of the contact finger 2 seat 1 is provided with a limiting groove 53, the The contact finger 2 is arranged along the circumference of the contact finger 2 seat 1 and is slidably connected with the end of the contact finger 2 seat 1. One side of the contact finger 2 is provided with a limit block 4 that conflicts with the limit groove 53 and the other At least one groove 5 is provided on the side, and at least one ring spring 6 is also included. The ring spring 6 is matched with the groove 5 on each contact finger 2. When the conductive rod is inserted into the contact finger 2 assembly, the contact finger 2 is held by the spring Pressing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com