Self-clamping insulated cable puncture clamp

A technology for insulating cables and puncture wire clips, applied in circuits, electrical components, conductive connections, etc., can solve problems such as poor waterproofing, loose and oxidized holding forces of the two glands, and achieve the effect of lowering temperature and facilitating clamping operations.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

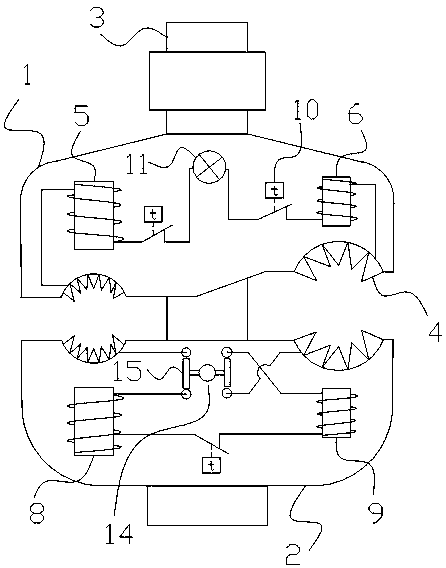

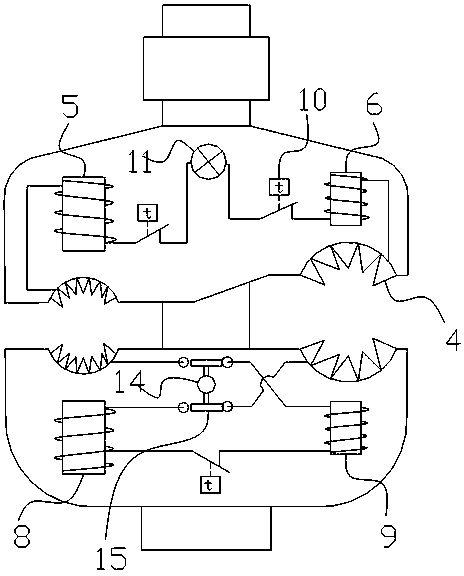

[0026] Such as figure 1 , 2 , 3, a self-clamping insulated cable puncture clamp, including the first gland 1 and the second gland 2, the fastening bolt 3 passing through the gland, and the clamps on both sides of the fastening bolt For the left and right card slots for clamping the cable, each card slot is composed of two half card slots opposite to each other on the first gland and the second gland, and a piercing blade 4 is arranged in the half card slot; A first left electromagnet 5 and a first right electromagnet 6 are respectively arranged above the left and right two draw-in slots on the gland. The piercing blades in the two draw-in slots are electrically connected, and the second gland is provided with a second left electromagnet 8 and a second right electromagnet corresponding to the first left electromagnet and the first right electromagnet on the first gland. 9. The second left electromagnet is connected in series with the second right electromagnet, and the two en...

Embodiment 2

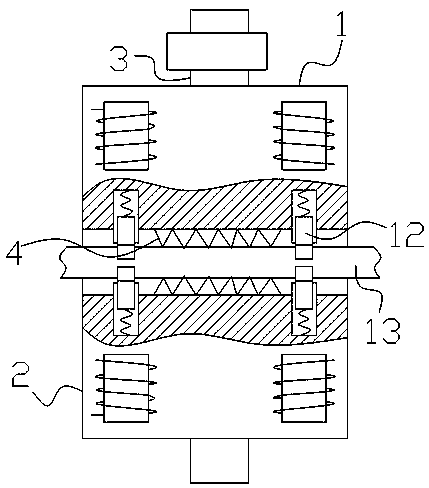

[0033] Such as Figure 4As shown, in the above, the bolts between the two glands are covered with springs, the springs are double-way memory alloy springs 16, and the two ends of the springs are electrically connected to the piercing blades of the left and right slots through wires. The spring is stretched at normal temperature, and it is supported between the two cover plates to open the two cover plates to facilitate the insertion of the wire into the slot; when the current passes through the spring, the temperature of the spring increases, causing the spring to contract, thereby facilitating Clamping of the two cover plates. The fastening bolt is a polished rod without thread. In order to facilitate the movement of the cover plate along the polished rod. During installation, pressurize the two glands to clamp the cable, and then rely on the electromagnetic force of the electromagnet to maintain the clamping force. When the puncture clamp needs to be removed, the current i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com