Highly random acrylamide-acrylic acid copolymers

A technology of acrylamide and copolymer, which is applied in the field of copolymers of acrylamide and acrylic acid and their cross-linked products, and can solve problems such as ammonia escape and large amounts of heat energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0089] A water-in-oil latex was formed using the components shown in Table 1.

[0090] Table 1. w / o latex polymerized components of AM and AA.

[0091]

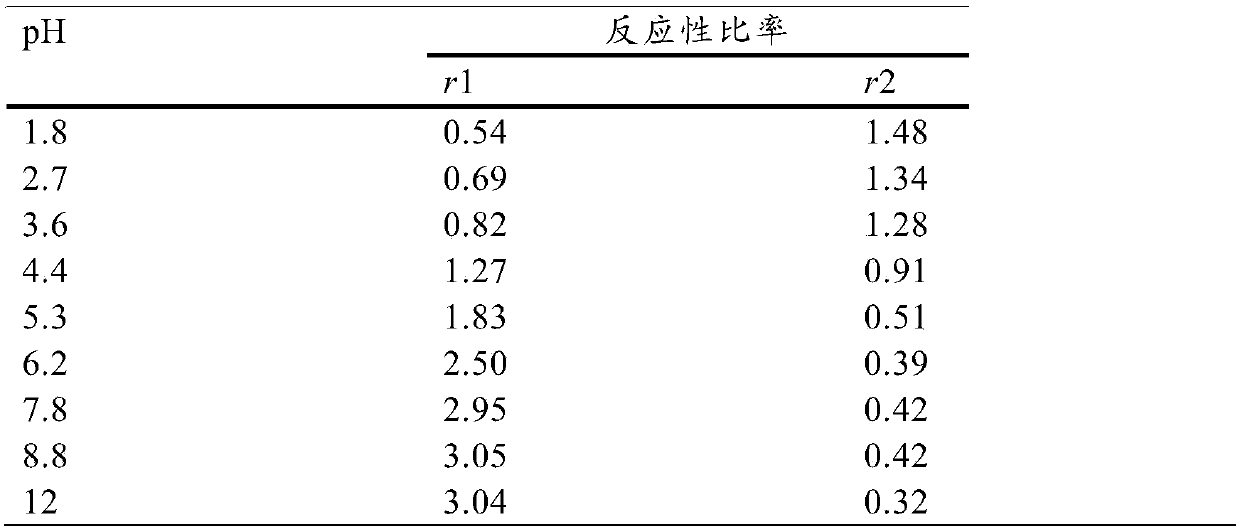

[0092] A latex was formed by mixing the components of the aqueous and oil phases separately and then combining them in a reaction vessel with vigorous agitation using an overhead paddle mixer followed by sparging the latex with nitrogen. The pH of the aqueous phase was measured to be 3.7. After mixing is complete, the initiator composition is added to the container and the container is sealed. The contents of the vessel were heated to about 40°C with stirring for about 4 hours. The reprocessing material is then added to the container. The resulting neutralized w / o latex was stable after cooling to ambient laboratory temperature and showed no signs of destabilization (segregation, flocculation formation) during the procedure. The latex was observed to be stable on storage under ambient laboratory conditions.

[0093]...

Embodiment 2

[0097] A water-in-oil latex comprising the materials shown in Table 2 was formed using the same procedure outlined above for Example 1 .

[0098] Table 2. w / o latex polymerized components of AM and AA.

[0099]

[0100] The resulting w / o latex was stable after cooling to ambient laboratory temperature and showed no signs of destabilization (segregation, flocculation formation) during the procedure.

[0101] Measured according to the procedure of Example 1, the reduced viscosity (RSV) of the latex is 30dL / g.

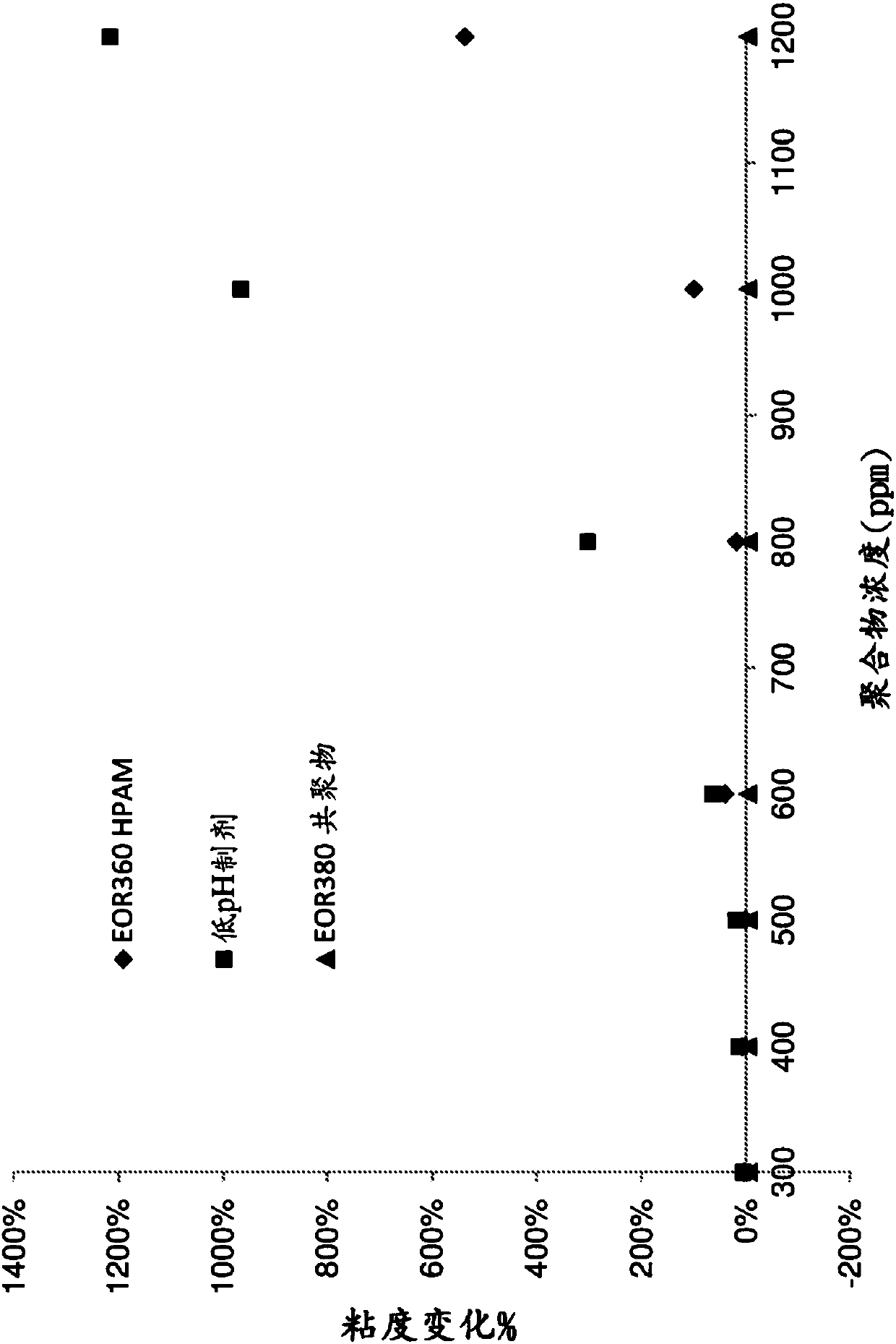

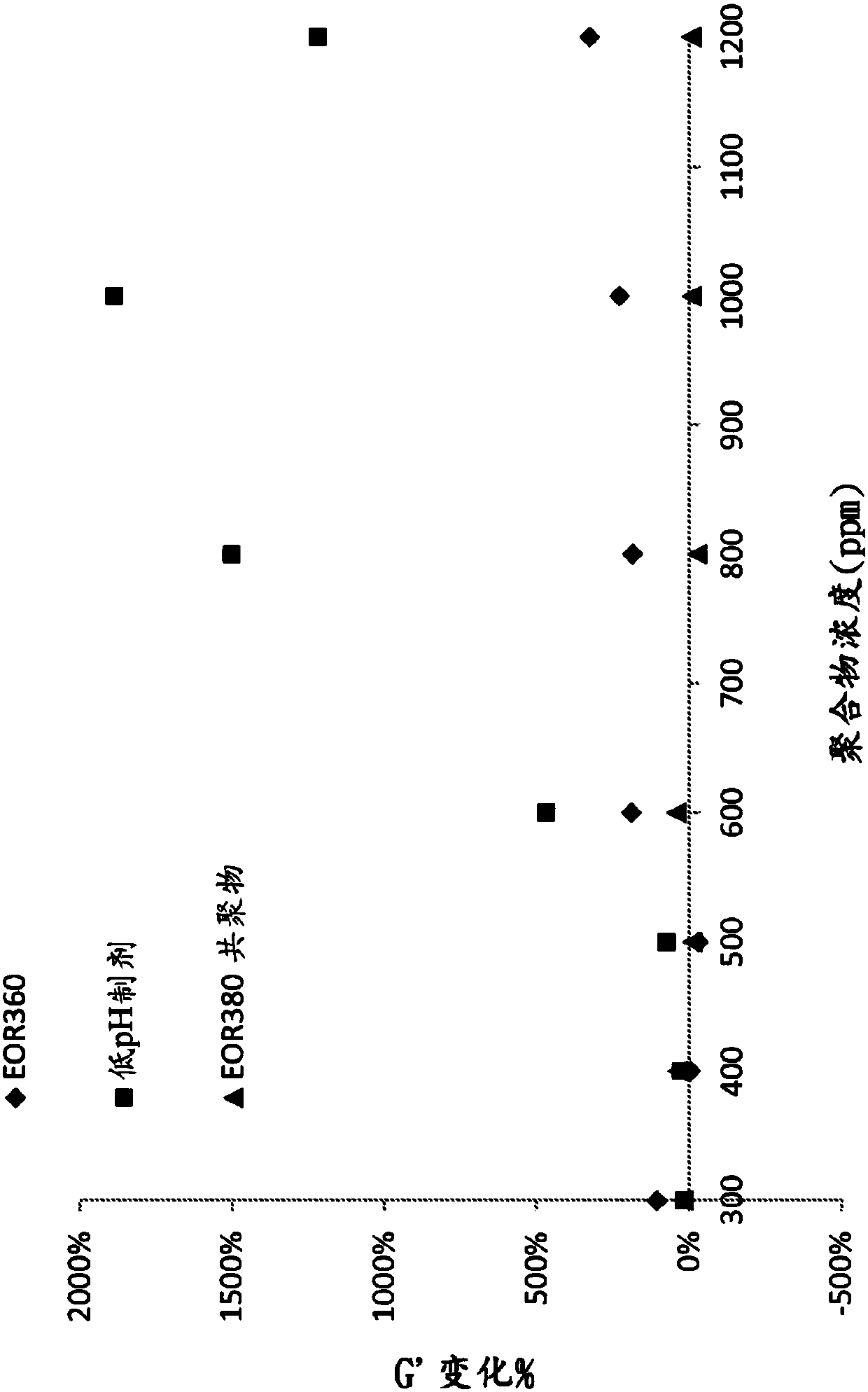

[0102] A portion of the latex was diluted to the concentrations shown in Table 3 using a solution of aluminum citrate in 1% NaCl, and the initial viscosity and 5 day / 50°C aged viscosity were measured according to the procedure of Example 1. The results are shown in Table 3.

Embodiment 3

[0104] EOR360 was obtained from TIORCO of Denver, CO. EOR360 is a PAM homopolymer which upon post hydrolysis yields a 70 / 30 mole / mole acrylamide / acrylic acid functionality ratio.

[0105] The polymer had a reduced viscosity (RSV) of 45 dL / g as measured according to the procedure of Example 1.

[0106] The polymer was diluted to the concentration shown in Table 3 using a solution of aluminum citrate in 1% NaCl, and the initial viscosity and 5 day / 50°C viscosity were measured according to the procedure of Example 1. The results are shown in Table 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Reduced viscosity | aaaaa | aaaaa |

| Reduced viscosity | aaaaa | aaaaa |

| Reduced viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com