Blanching machine

A technology for blanching machines and casings, applied in the field of blanching machines, which can solve the problems of affecting the quality of finished products, poor blanching effect, and inconsistent cooling temperature and time, and achieve the effect of reducing debris and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

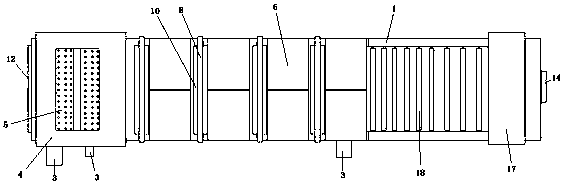

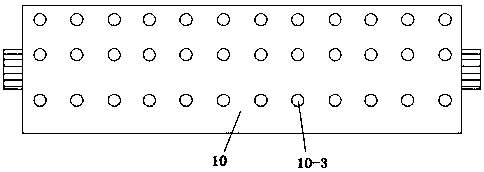

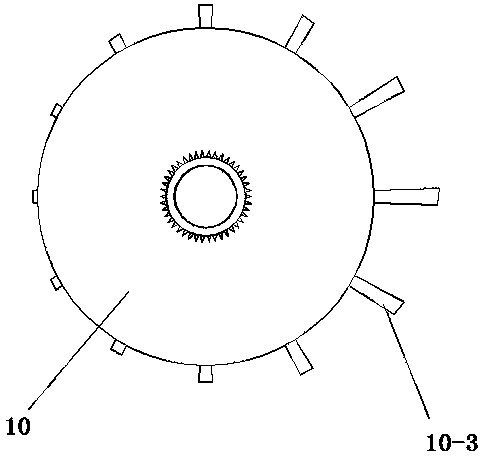

[0020] like figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 As shown, a blanching machine includes a hollow box-packed casing 1, the upper top surface of the casing 1 is an open surface, and the left and right sides of the top of the casing 1 are respectively set as a material inlet and a material outlet. There are a belt conveyor 2, a motor 3, a nozzle and a water heating device. A hopper 4 is arranged above the material inlet on the casing 1. The hopper 4 makes the material enter a designated area. Below the material inlet, between the belt conveyor 2 A pair of horizontal first rollers 5 are arranged between them. There is a gap between the two first rollers 5. The gap is located directly below the hopper 4. The first roller 5 is driven by the motor 3 through the belt, and the two rollers rotate relatively. The upper top surface of the casing 1 is provided with four groups of doors 6, and the four groups of doors 3 are arranged and distributed along the conveyi...

Embodiment 2

[0025] Further optimization, the outer circular surface of the second roller is provided with a connecting buckle, and a pressing plate is arranged on the connecting buckle, and the pressing plate has a better pressing effect on the spherical material, thereby blanching a better product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com