Glass chip clearing device used for glass forming machine

A cleaning device and molding machine technology, applied in the direction of cleaning method, cleaning method and utensils, chemical instruments and methods using gas flow, etc., can solve the problems of unsatisfactory efficiency, unsatisfactory, low efficiency, etc., to improve blowing efficiency , easy maintenance and maintenance, simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

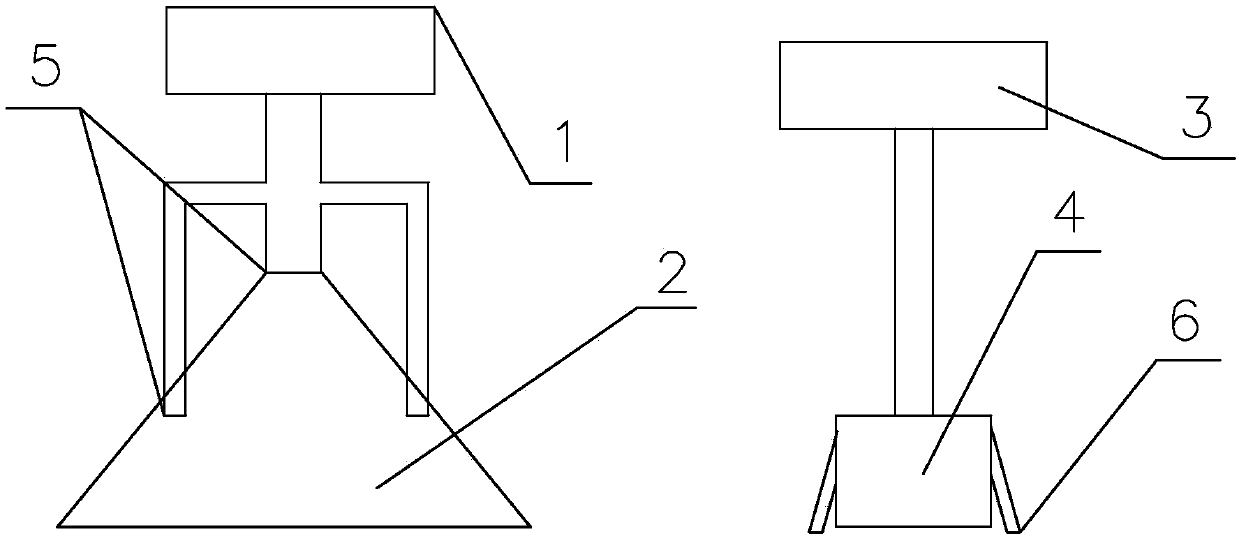

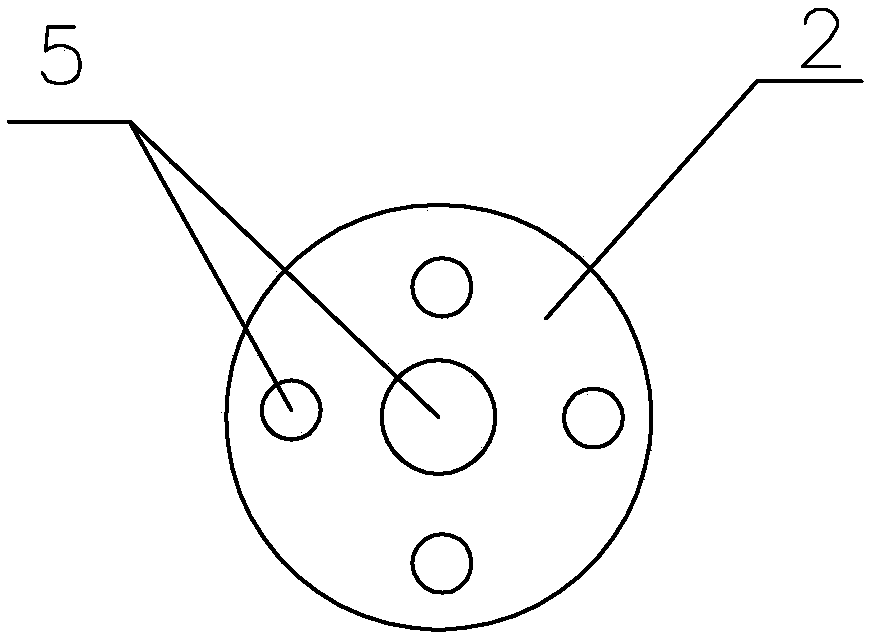

[0023] Such as Figure 1~3 As shown, the present invention comprises: vacuum suction device and compression blow-off device, and vacuum suction device comprises vacuum pump 1 and suction head 2, and compression blow-off device comprises compressor 3 and blow-off head 4, and described suction head 2 is a conical structure, five suction pipes 5 are arranged under the conical structure, and the suction pipes 5 are all connected to the vacuum pump 1 through pipelines;

[0024] A suction pipe 5 is arranged at the center of the suction head 2 , and other suction pipes are evenly arranged on the tapered structure part of the suction head 2 .

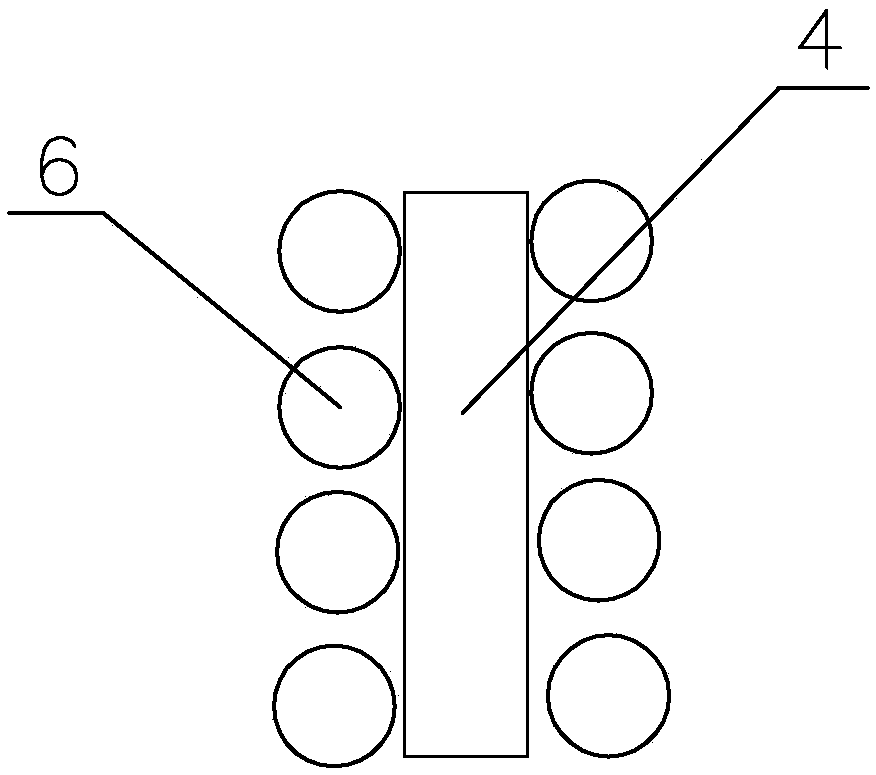

[0025] The blow-off head 4 is arranged in a rectangular shape, and blow-off pipes 6 are uniformly arranged on both sides of the blow-off head 4 .

[0026] The blowing direction of the blowing pipe 6 is 10° away from the direction of the blowing head 4 .

[0027] The direction of the suction pipe 5 is vertically downward.

[0028] The diamete...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com