Device and method for eliminating eccentricity of tool and main shaft of machine tool

A technology of eccentric device and machine tool spindle, which is applied in the direction of positioning device, feeding device, automatic control device, etc., can solve the problems of limited reduction and unsatisfactory effect, and achieve the effect of simple structure, improved processing quality and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

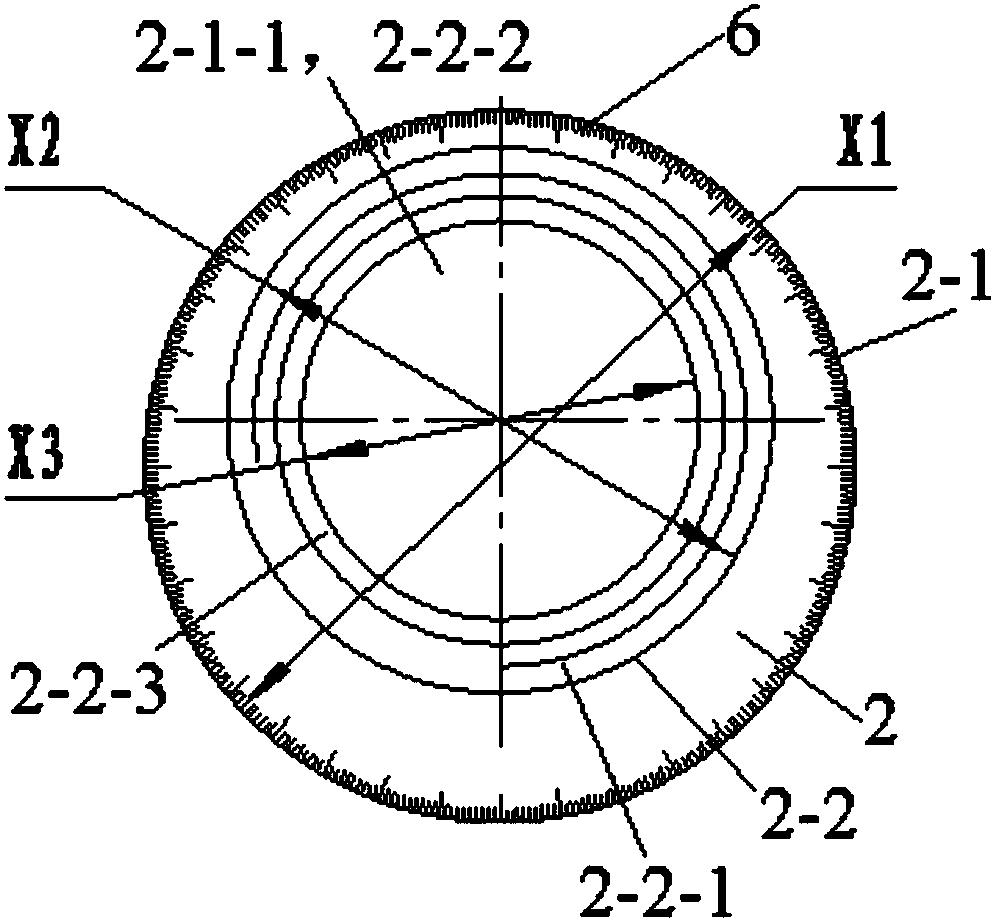

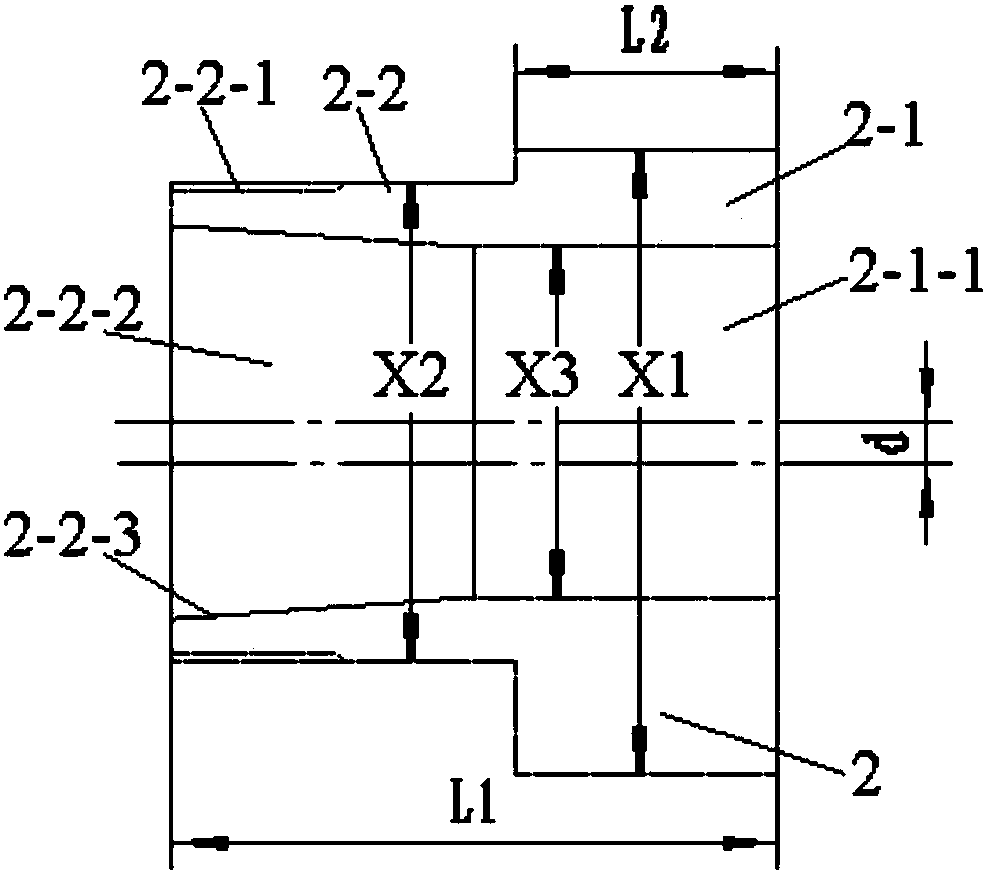

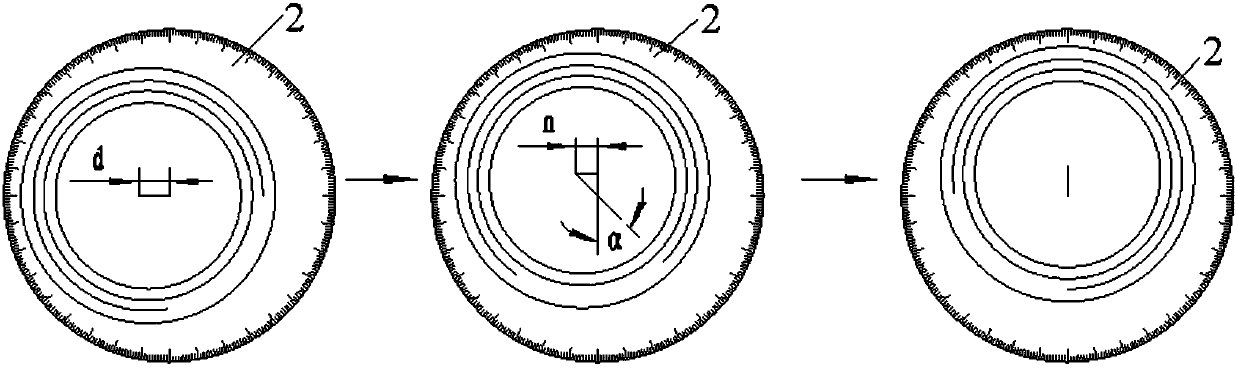

[0055] Taking a CNC machine tool as an example, the eccentricity problem after installation of the boring tool is corrected by making an eccentric adapter sleeve. The specific implementation method is as follows, as follows: Figure 4 Shown:

[0056] (1) Measure the diameter of the tool mounting hole of the tool mounting seat 1 of the machine tool to be Φ20mm;

[0057] (2) After the boring tool 5 with a diameter of Φ4mm is mounted on the tool handle by clamping spring 3, the boring tool 5 together with the tool handle is installed on the machine tool, and the axis of the boring tool 5 deviates from the center of the machine tool spindle by making a watch. The maximum eccentricity is 2mm;

[0058] (3) According to the principle of 20-2×2>X3, the diameter X3 of the first inner hole 2-1-1 of the eccentric device 2 is determined to be Φ12mm;

[0059] (4) According to the principle of X2-Φ12>5 and the standard of the clamp spring 3 used for clamping the machine tools, determine t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com