Eccentric moment converter

An eccentric torque and converter technology, applied in the field of torque converters, can solve problems such as numerical distortion, and achieve the effects of easy assembly and disassembly, reliable connection and easy installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

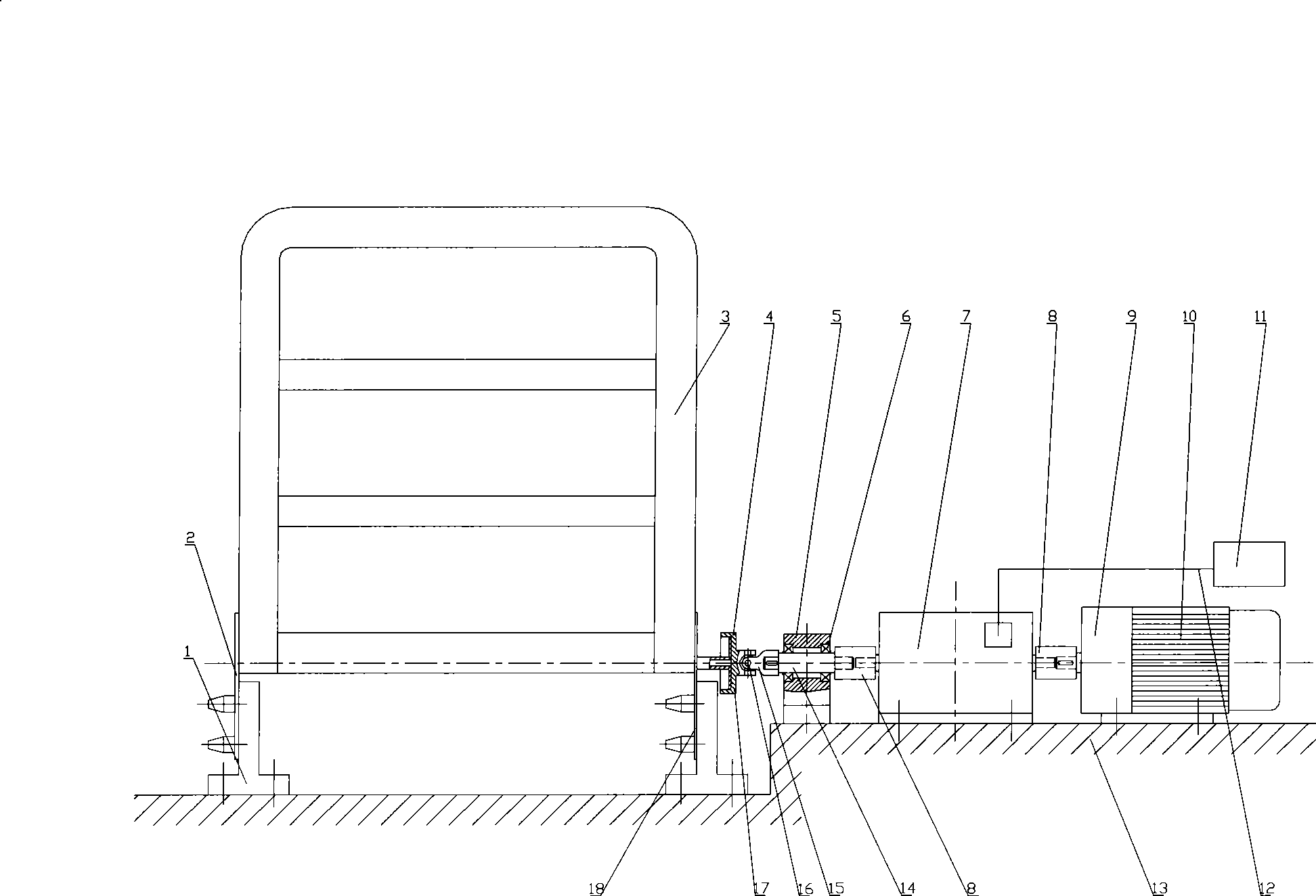

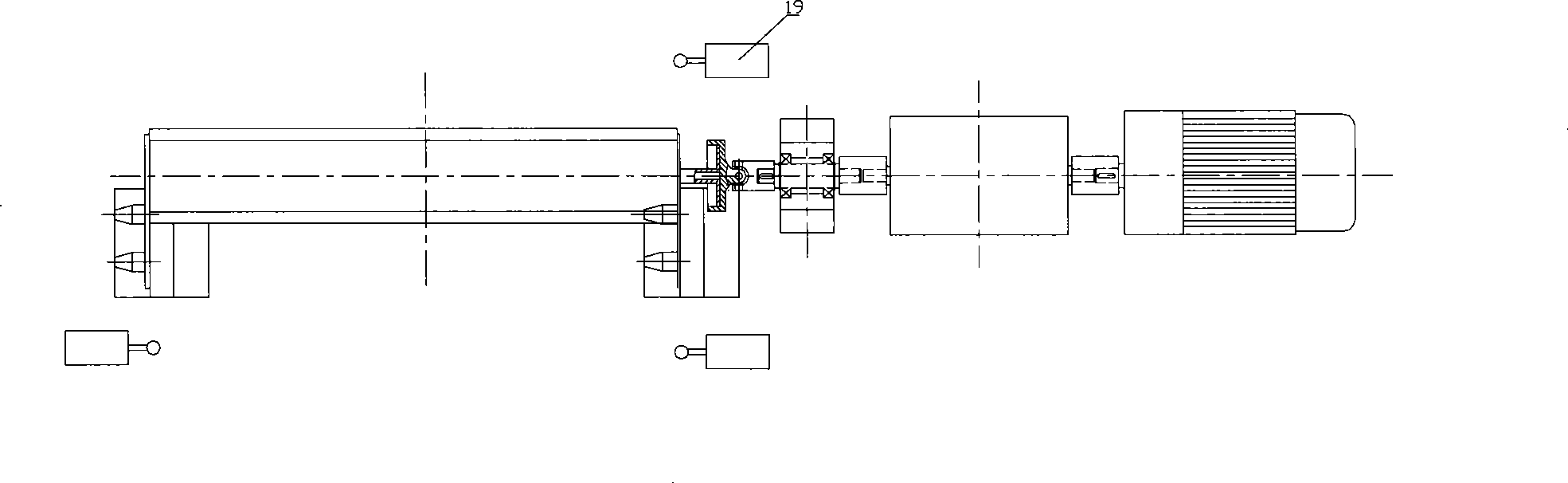

[0016] Such as figure 1 , shown in 2, apply the automobile seat recliner torque performance test bench of the present invention,

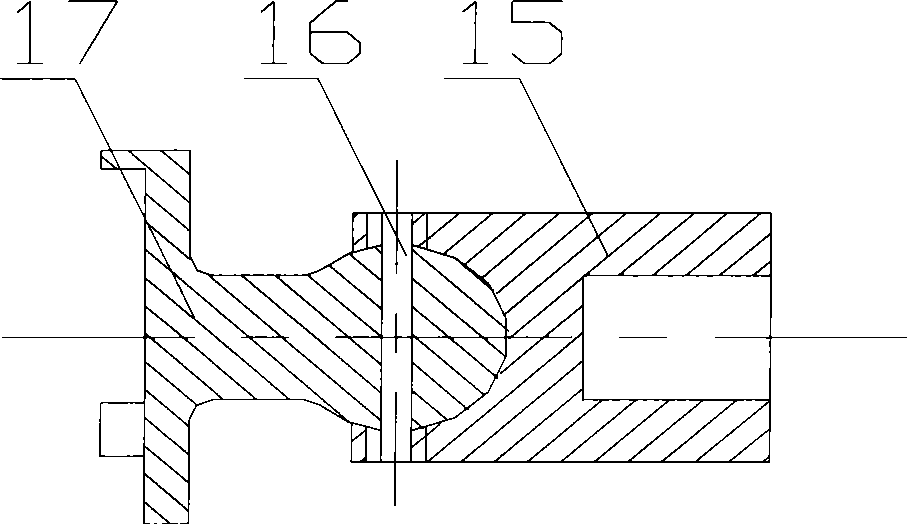

[0017] Including tooling 1, seat recliner 2, seat frame upper body 3, seat turntable yoke 4, bearing support 5, rolling bearing 6, torque sensor 7, flexible coupling 8, reducer 9, drive motor 10 , Torque meter 11, signal line 12, workbench 13, small shaft 14, fixed end spherical joint 15, pin shaft 16, yoke type free end ball joint 17, seat frame lower body 18, limit switch 19.

[0018] The other side of the fixed-end spherical joint 15 is connected with the small shaft 14. A pair of bearings 6 are installed on the small shaft 14 and mounted on the bearing seat 5. The output shaft of the shaft is connected with the output shaft of the torque sensor 7 through a coupling 8. The torque The shaft at one end of the sensor 7 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com