Caterpillar track efficient loading equipment

A kind of equipment and high-efficiency technology, applied in conveyors, conveyor objects, transportation and packaging, etc., can solve the problems of reducing equipment use time, motor overload operation, affecting feeding speed, etc., to reduce pulling force, reduce Load, improve the effect of feeding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

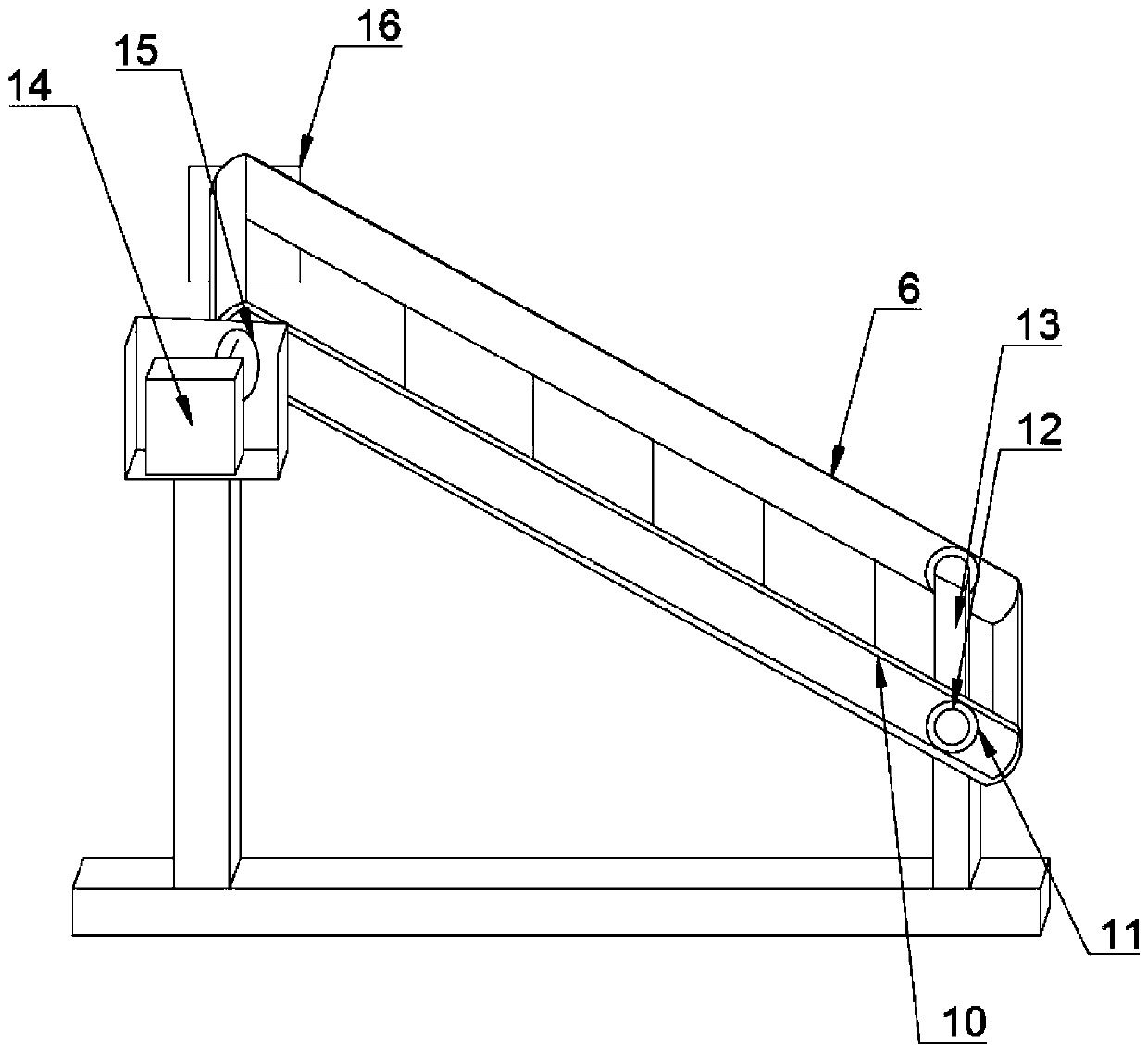

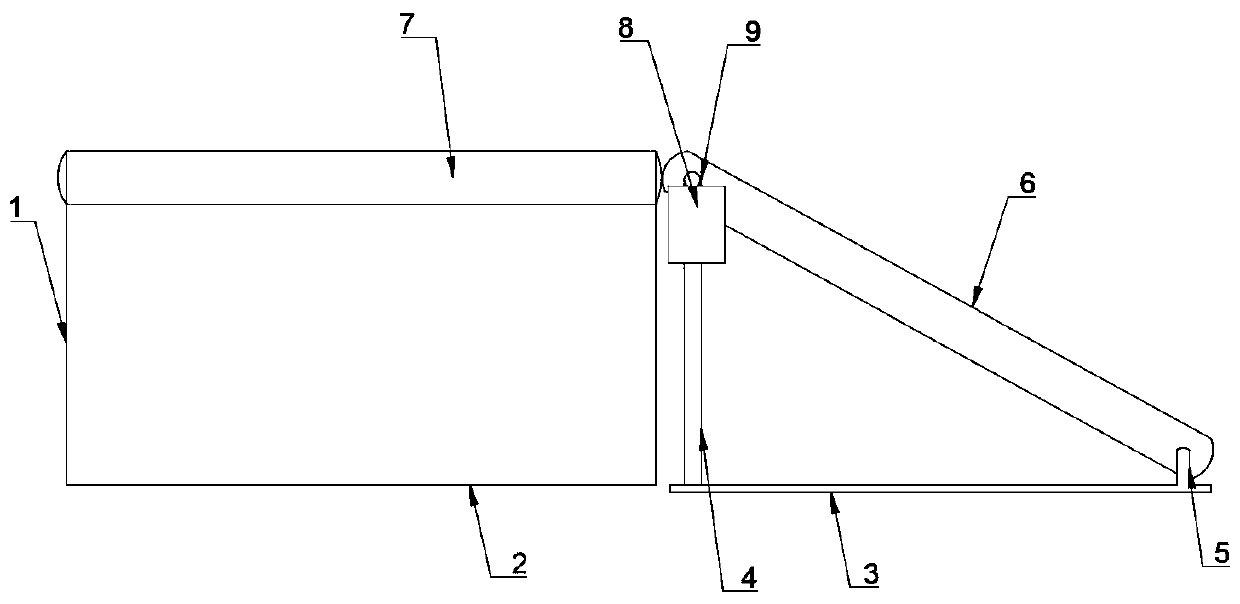

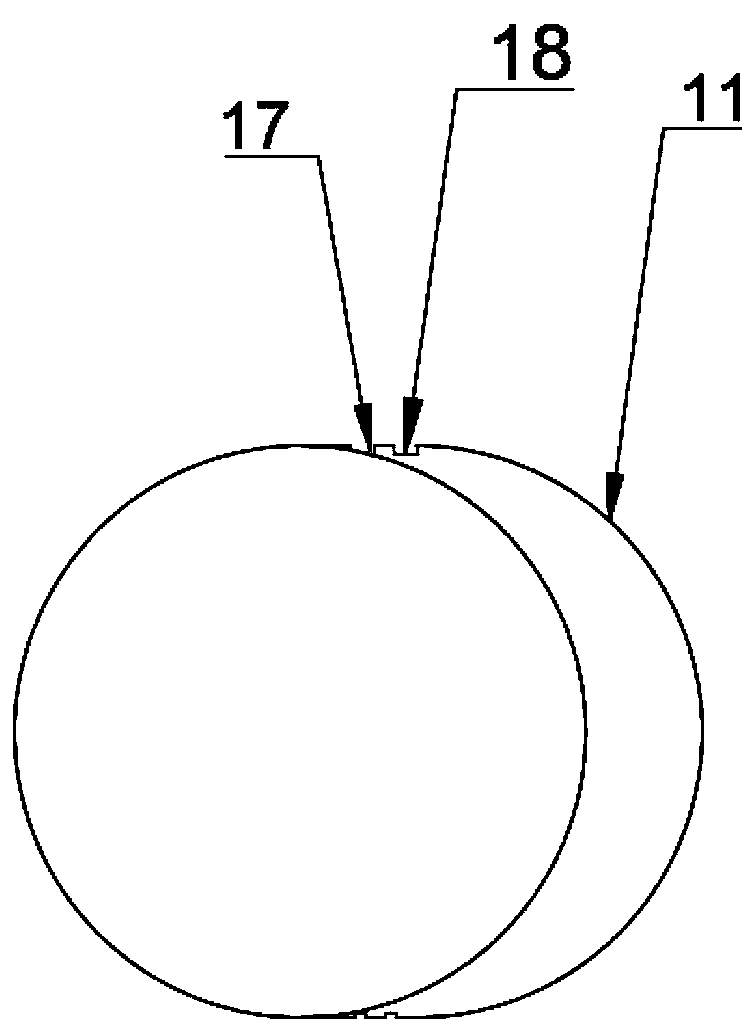

[0020] Such as Figure 1-4 As shown, the present invention provides a kind of high-efficiency crawler feeding equipment, comprising a device body 1, a first base 2 is provided at the bottom of the device body 1, a second base 3 is provided on one side of the first base 2, and a second base 3 is provided on one side of the first base 2. 3 are respectively provided with a first support column 4 and a second support column 5, the surface of the first support column 4 is respectively provided with a first power assembly 8 and a second power assembly 16, and the inside of the first power assembly 8 is provided with Motor 14, one side of the motor 14 is provided with a reel 15, the top of the first support column 4 is provided with a fixed housing 6, the surface of the fixed housing 6 is provided with several rotating shafts 9, and the inside of the fixed housing 6 is provided with a rolling track 10. The surface of the rolling track 10 is provided with a bump 19, and the inner side...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com