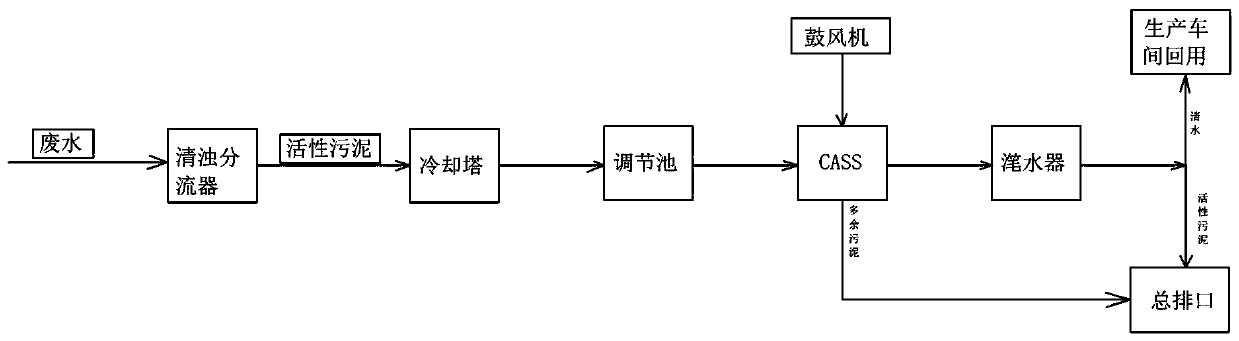

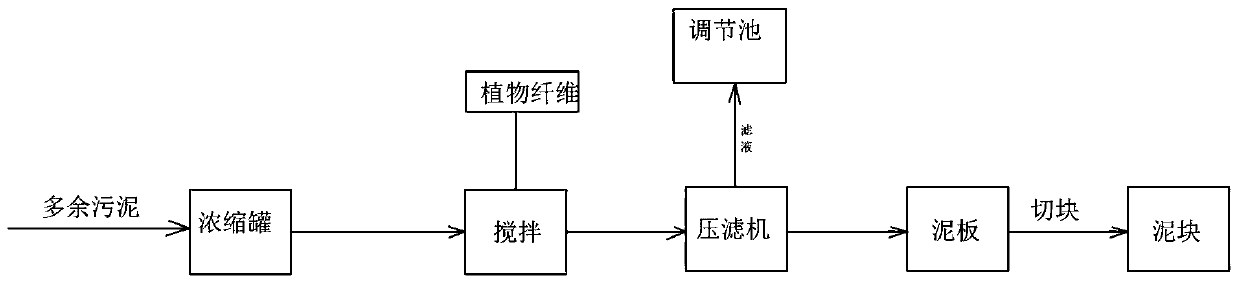

CASS (Cyclic Activated Sludge Technology) treatment method for activated sludge in beet sugar wastewater

A technology of activated sludge and treatment methods, applied in water/sludge/sewage treatment, sludge treatment, dehydration/drying/thickened sludge treatment, etc., can solve problems affecting the quality of ash and residue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

[0030] Put the cut mud blocks in the combustion furnace, first keep warm at 120°C for 2 hours, and carry out sintering and combustion of organic matter; then gradually raise the temperature to 1200°C, hold for 8 hours, and carry out mud board sintering; finally within 2 hours, gradually cool down to 500°C, gradually cool down to 200°C within 1 hour, and gradually cool down to 20°C within 3 hours.

Embodiment example 2

[0032] Put the cut mud blocks in the combustion furnace, first keep warm at 150°C for 3 hours, and sinter and burn organic matter; then gradually increase the temperature to 1200°C, keep warm for 10 hours, and carry out sintering of clay plates; finally, gradually cool down to within 2 hours 500°C, gradually cool down to 200°C within 1 hour, and gradually cool down to 20°C within 3 hours.

Embodiment example 3

[0034] Put the cut mud blocks in the combustion furnace, first keep warm at 200°C for 4 hours, and carry out sintering and combustion of organic matter; then gradually raise the temperature to 1200°C, keep warm for 12 hours, and carry out mud board sintering; finally within 2 hours, gradually cool down to 500°C, gradually cool down to 200°C within 1 hour, and gradually cool down to 20°C within 3 hours.

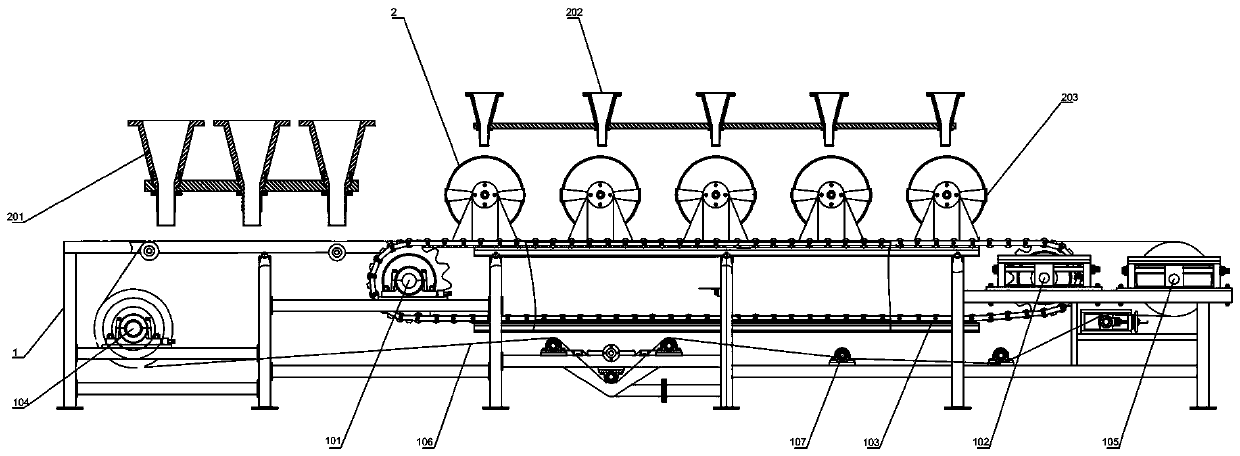

[0035] Such as image 3 A filter press shown includes a conveying device, a feeding device and a pressing device, and a feeding device and a pressing device are arranged above the conveying device;

[0036] Described conveying device comprises frame 1, driving sprocket 101, driven sprocket 102, conveying chain 103, driving roller 104, driven roller 105, conveying mesh belt 106, tensioning roller 107, lower hopper group a201 and pressure wheel 2. The two ends of the frame 1 are respectively provided with a driving roller 104 and a driven roller 105, and a conveying mesh belt 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com