Gas-liquid-solid three-phase separator

A three-phase separator, gas-liquid-solid technology, applied in chemical instruments and methods, biological water/sewage treatment, water/sludge/sewage treatment, etc. Fast and efficient separation results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

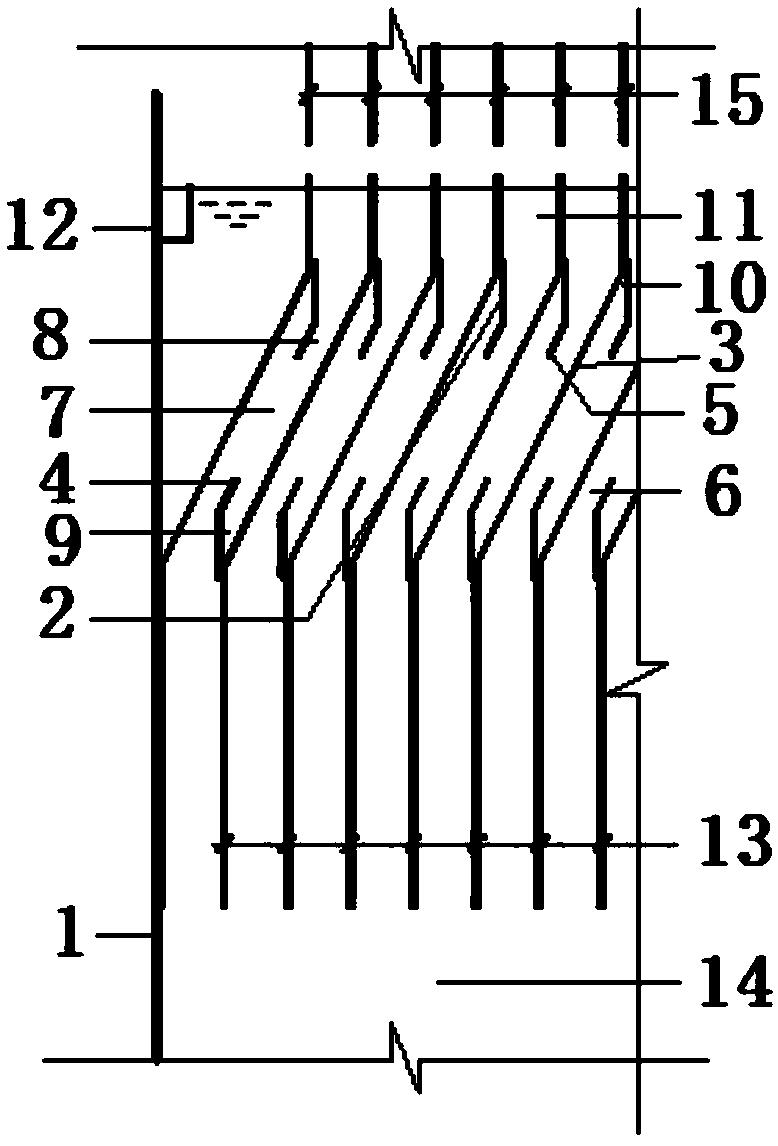

[0011] The main structure of the gas-liquid-solid three-phase separator involved in this embodiment includes a tank body 1, a folded-plate inclined plate 2, an air-cement mixing gap 6, an air-cement separation area 7, a clear water gap 8, a mud collection area 9, and a gas collection area 10. Clean water area 11, outlet channel 12, sludge return pipe 13, reaction area 14 and biogas pipe 15; inside the tank body 1 of the hollow structure, there are several folded plate sloping plates 2 of S-shaped plate structure, The folded plate type slant plate 2 is composed of a slant plate 3, an upper folded plate 4 and a lower folded plate 5. The front end of the inclined plate 3 with an inclined plate structure is provided with an upper folded plate 4 with an L-shaped plate structure bent upwards. The rear end of the inclined plate 3 is provided with the lower folded plate 5 of the L-shaped plate structure bent downwards, the horizontal plane where the top point of the upper folded plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com