Vacuum pumping system and its use method, vacuum refining system

A vacuum pumping system and vacuum pumping technology, applied in the field of metallurgy, can solve the problems of the Laval nozzle effect, the large selection of liquid ring vacuum pump pumping capacity, and the influence of vacuum pumping efficiency in the pre-pumping stage, so as to facilitate production maintenance and reduce The effect of energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

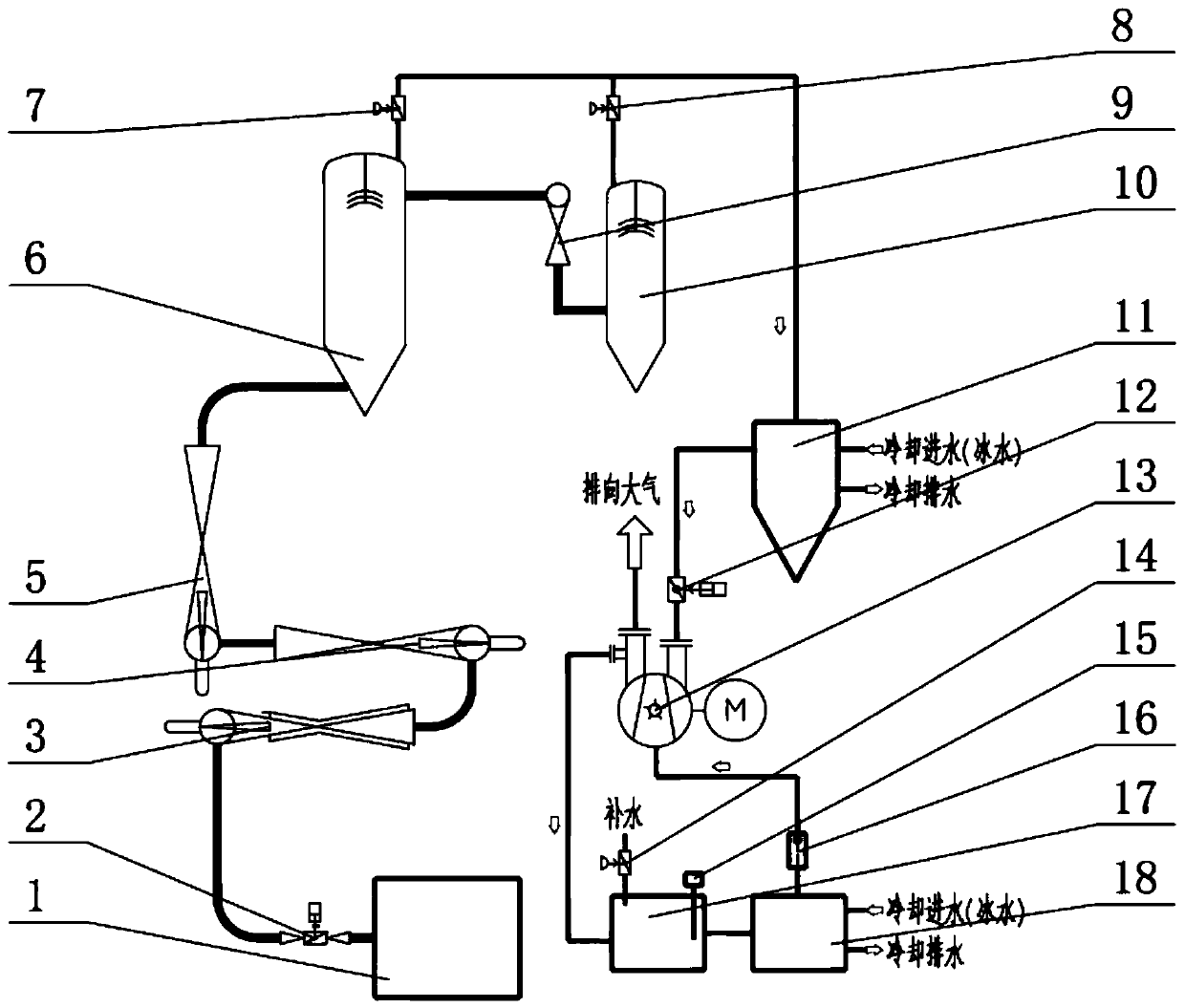

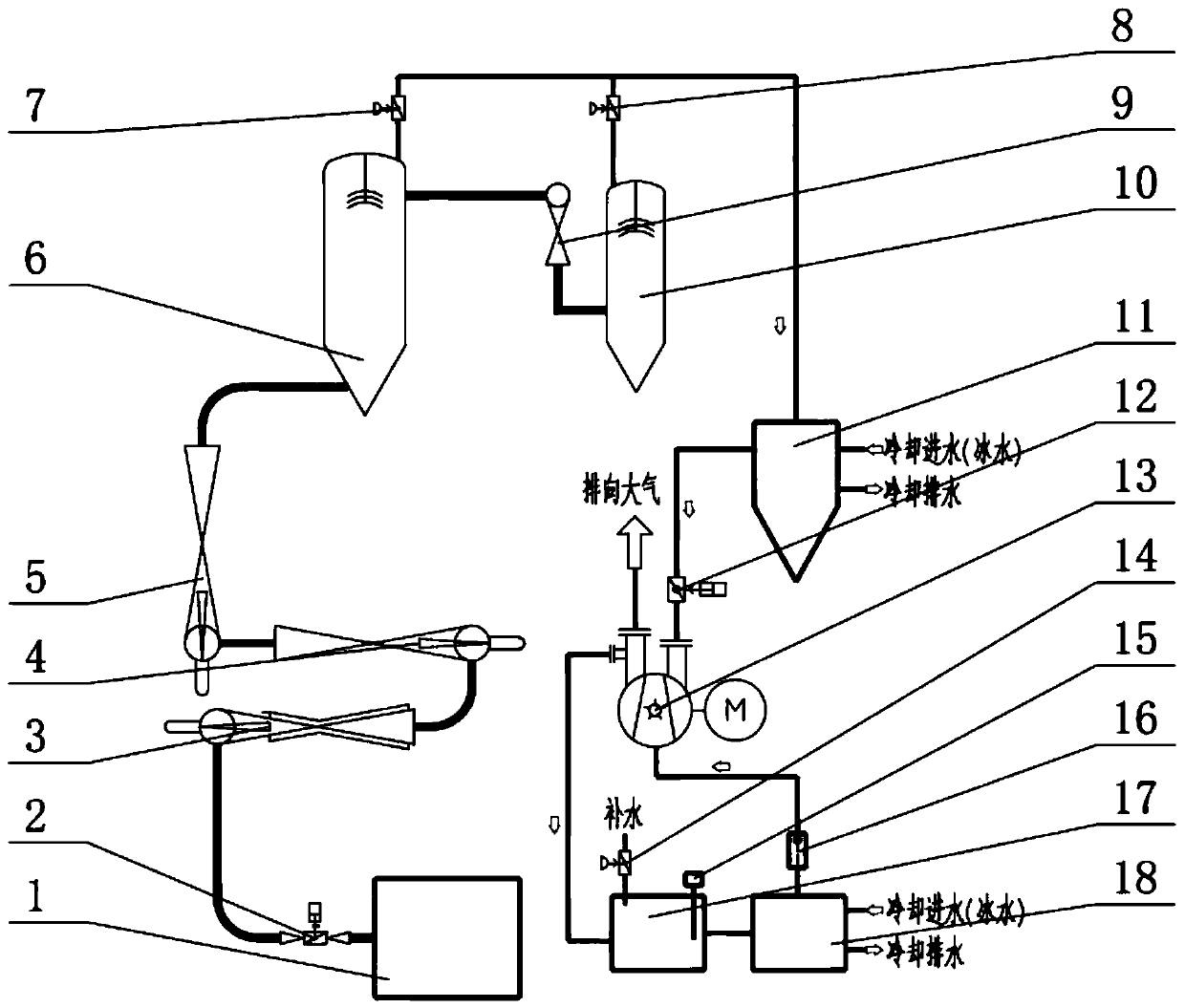

[0025] Such as figure 1 , an embodiment of the present invention provides a vacuum pumping system, including a steam jet pump assembly and a liquid ring pump 13 connected in series through the pumping pipeline, and the steam jet pump assembly includes at least one stage of steam jet pump assembly connected in series along the pumping direction. The jet pump is also equipped with at least one auxiliary suction pipe (illustrated, not marked) for preventing the steam jet pump from producing the Laval nozzle effect, and each of the auxiliary suction pipes is connected to the corresponding steam jet pump On the suction pipe between the steam jet pump of the previous stage and its outlet end communicates with the liquid ring pump 13 , each of the auxiliary suction pipes is provided with a first control valve 7 . Generally, along the air extraction direction, the more rearward the steam jet pump is, the higher the possibility of producing the Laval nozzle effect is, and the above-men...

Embodiment 2

[0036] The embodiment of the present invention relates to a vacuum refining system, including a vacuum chamber 1 and a vacuum pumping subsystem connected to the pumping port of the vacuum chamber 1. The vacuum chamber 1 is used as a reaction place for molten steel. The vacuum pumping subsystem is preferably The specific structure of the vacuum pumping system provided in Embodiment 1 above will not be repeated here. Wherein, a main vacuum valve 2 is provided on the pumping pipeline between the vacuum chamber 1 and the first-stage steam jet pump 3 to control whether the pumping subsystem works.

Embodiment 3

[0038] The embodiment of the present invention describes the method of using the vacuum pumping system provided in the first embodiment above. During the use of the vacuum pumping system, it includes:

[0039] In the pre-pumping stage, each of the steam jet pumps is on standby and serves as a gas channel, each of the first control valves 7 is opened, and the liquid ring pump 13 is running to extract the original gas in the pumped container 1;

[0040] When gas is generated in the pumped container 1, each of the first control valves 7 is closed, and each of the steam jet pumps and the liquid ring pump 13 is in operation;

[0041] When gas generation in the pumped container 1 stops, each of the first control valves 7 is closed, and each of the steam jet pumps is sequentially stopped in sequence, and then the liquid ring pump 13 is stopped.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com