A gear brake actuator for new energy vehicles

A technology of new energy vehicles and actuators, applied in the direction of brake actuators, brake types, gear transmission mechanisms, etc., can solve the problems of inability to achieve active braking and slow braking response, and achieve fast braking response and fast braking. smooth and reliable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

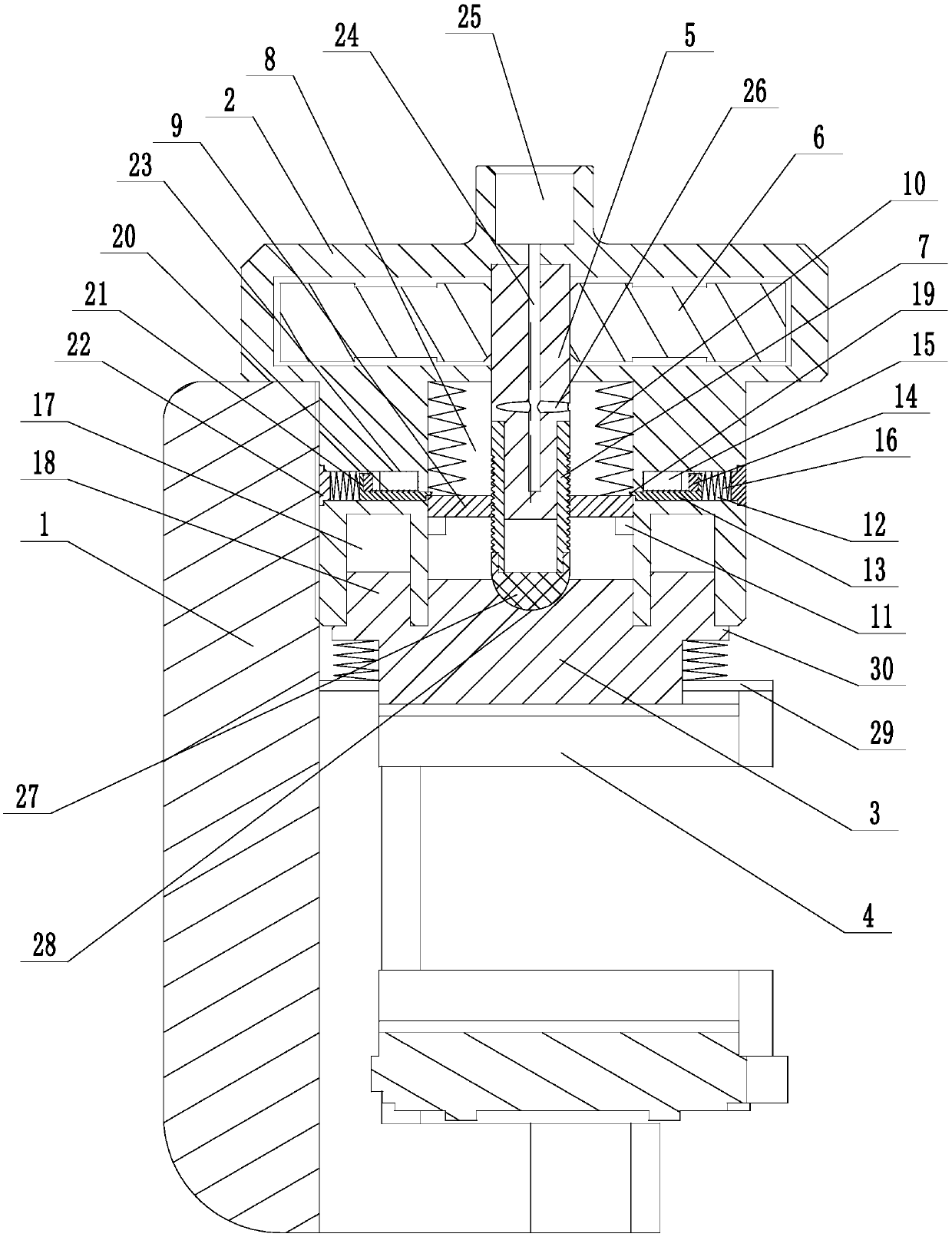

[0019] Embodiment: A gear brake actuator for new energy vehicles (see attached figure 1 ), including the caliper body 1, the housing 2 connected with the caliper body, the driving block 3, and the friction plate 4 connected with the driving block. A rotating shaft 5 is installed in the housing, and a gear 6 is installed on the rotating shaft, and the gear transmission is connected to the brake. The motor is slidably fitted with a threaded sleeve 7 on the rotating shaft, the anti-rotation connection between the threaded sleeve and the rotating shaft, a number of axially arranged connecting keys are evenly distributed on the outer wall of the rotating shaft, and a number of key grooves are arranged on the inner wall of the threaded sleeve and the connecting keys one by one. The key groove runs through to both ends of the threaded sleeve, and the connecting key and the key groove can be axially slidably connected. There is an installation chamber 8 inside the shell, and the threa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com