a gearbox differential

A gearbox and differential technology, applied in the direction of differential transmission, transmission, transmission parts, etc., can solve the problems of unsatisfactory heat dissipation efficiency and gear transmission efficiency, inconvenient installation, complex structure, etc., and achieve simple structure, Easy installation and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

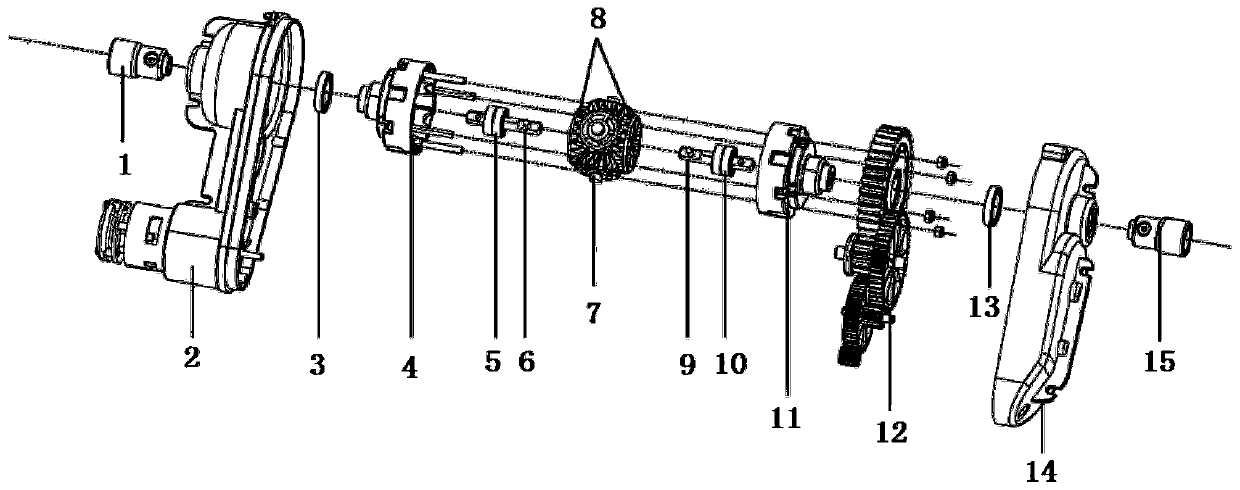

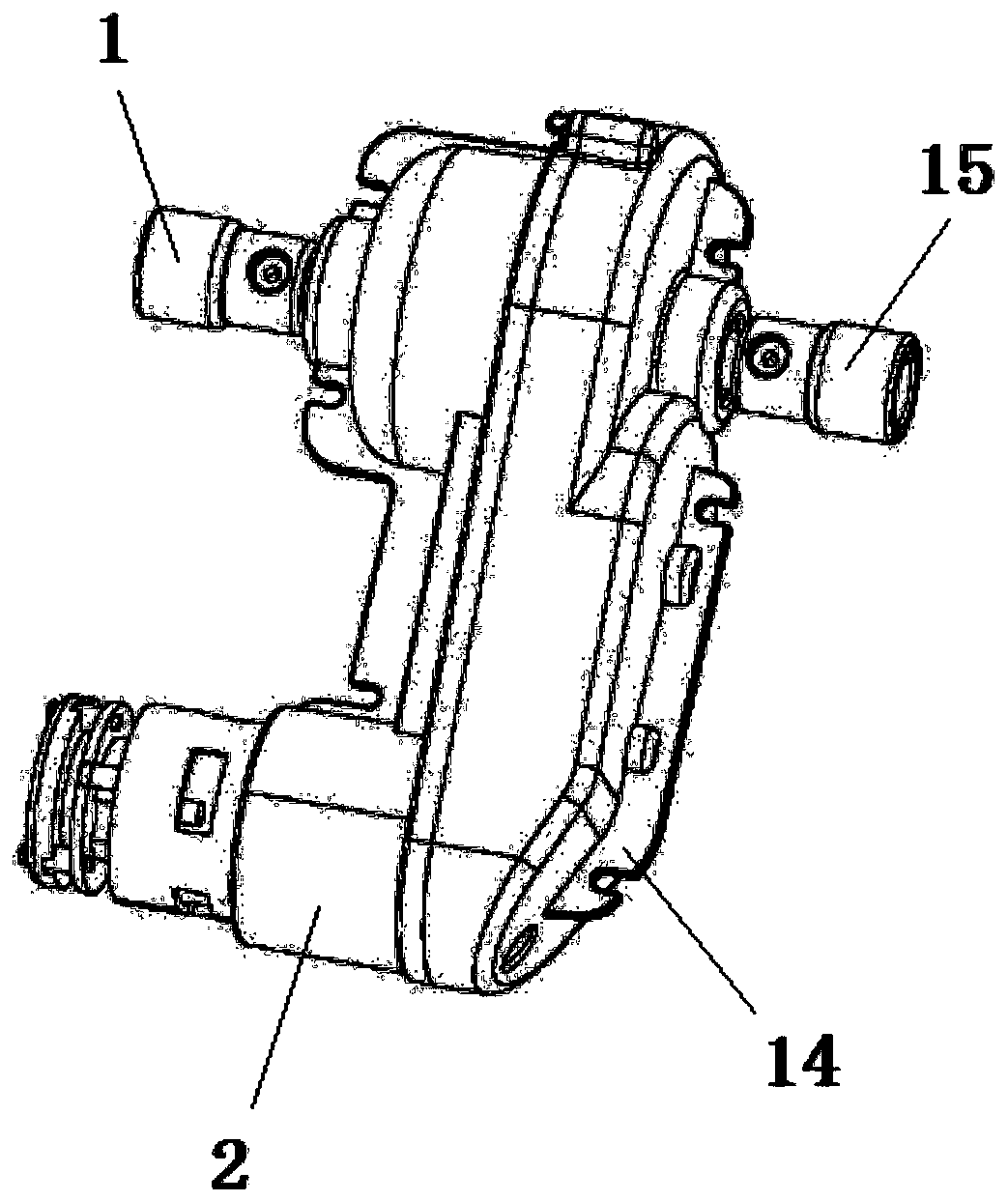

[0031] Such as figure 1 with figure 2As shown, the present invention provides a transmission differential, comprising a first conversion member 1, a first transmission case 2 and a second transmission case 14 sealed butted to form a transmission differential housing, a first differential Shell 4 and the second differential case 11 are sealed and butted to form a differential case, a speed change gear set 12 and a second conversion member 15, and the differential case and the speed change gear set 12 are installed in the gearbox differential case , the gearbox differential housing is externally connected to the first conversion member 1 and the second conversion member 15, and the inside of the differential housing formed by the sealing butt joint of the first differential housing 4 and the second differential housing 11 passes through the first The first output shaft 6 and the second output shaft 9 are equipped with a sun gear 8, the sun gear 8 is toothed with a planetary ge...

Embodiment 2

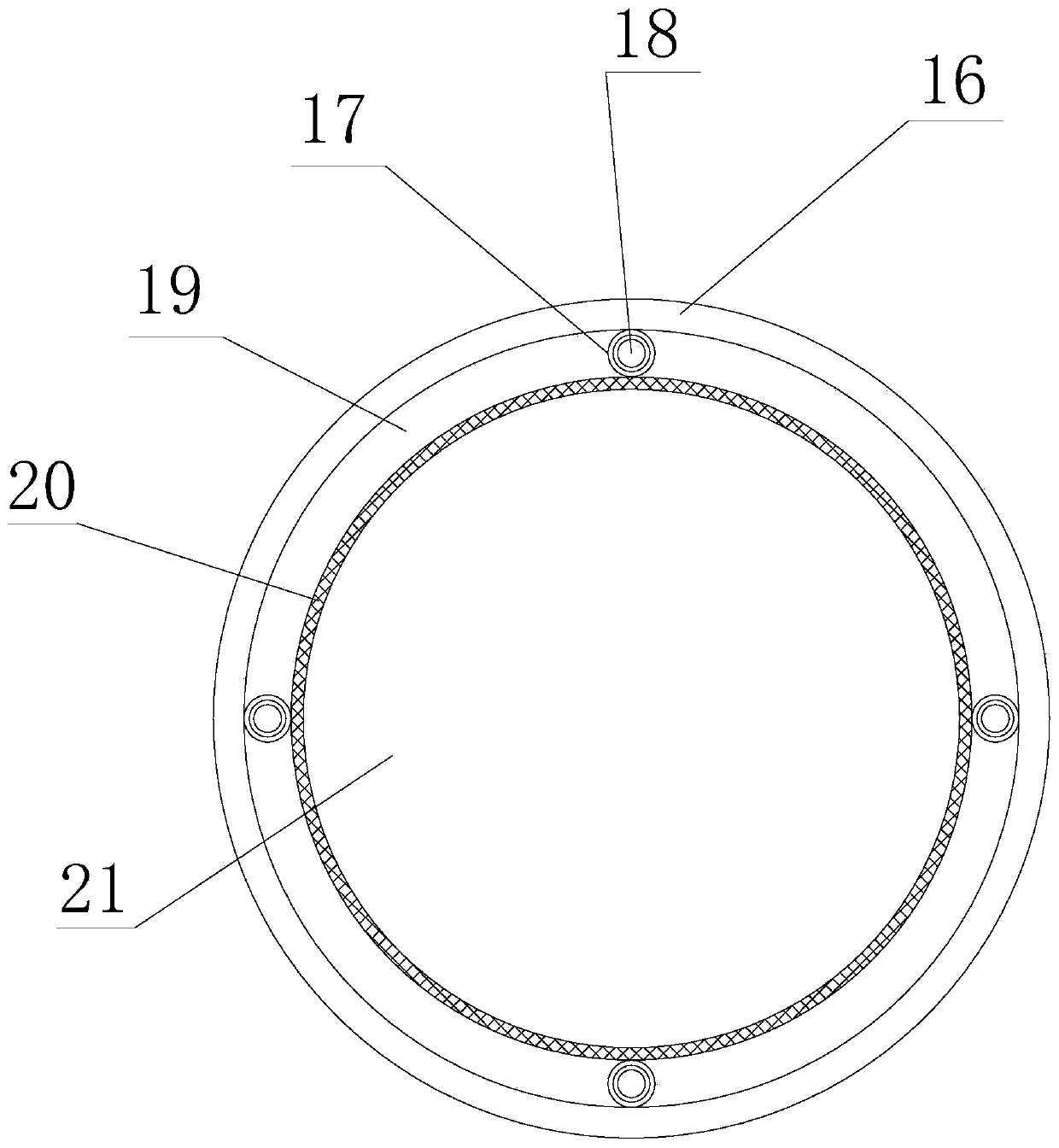

[0034] Such as figure 1 , figure 2 , image 3 with Figure 4 As shown, the present invention provides a transmission differential, comprising a first conversion member 1, a first transmission case 2 and a second transmission case 14 sealed butted to form a transmission differential housing, a first differential Shell 4 and the second differential case 11 are sealed and butted to form a differential case, a speed change gear set 12 and a second conversion member 15, and the differential case and the speed change gear set 12 are installed in the gearbox differential case , the gearbox differential housing is externally connected to the first conversion member 1 and the second conversion member 15, and the inside of the differential housing formed by the sealing butt joint of the first differential housing 4 and the second differential housing 11 passes through the first The first output shaft 6 and the second output shaft 9 are equipped with a sun gear 8, the sun gear 8 is t...

Embodiment 3

[0040] Such as figure 1 , figure 2 with Figure 5 As shown, the present invention provides a transmission differential, comprising a first conversion member 1, a first transmission case 2 and a second transmission case 14 sealed butted to form a transmission differential housing, a first differential Shell 4 and the second differential case 11 are sealed and butted to form a differential case, a speed change gear set 12 and a second conversion member 15, and the differential case and the speed change gear set 12 are installed in the gearbox differential case , the gearbox differential housing is externally connected to the first conversion member 1 and the second conversion member 15, and the inside of the differential housing formed by the sealing butt joint of the first differential housing 4 and the second differential housing 11 passes through the first The first output shaft 6 and the second output shaft 9 are equipped with a sun gear 8, the sun gear 8 is toothed with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com