Medicine material drying device

A drying device and technology for medicinal materials, applied in drying, drying machine, heating device and other directions, can solve the problems of scorched medicinal materials and uneven heating of medicinal materials to be dried, so as to avoid scorching, good drying effect, The effect of improving drying efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

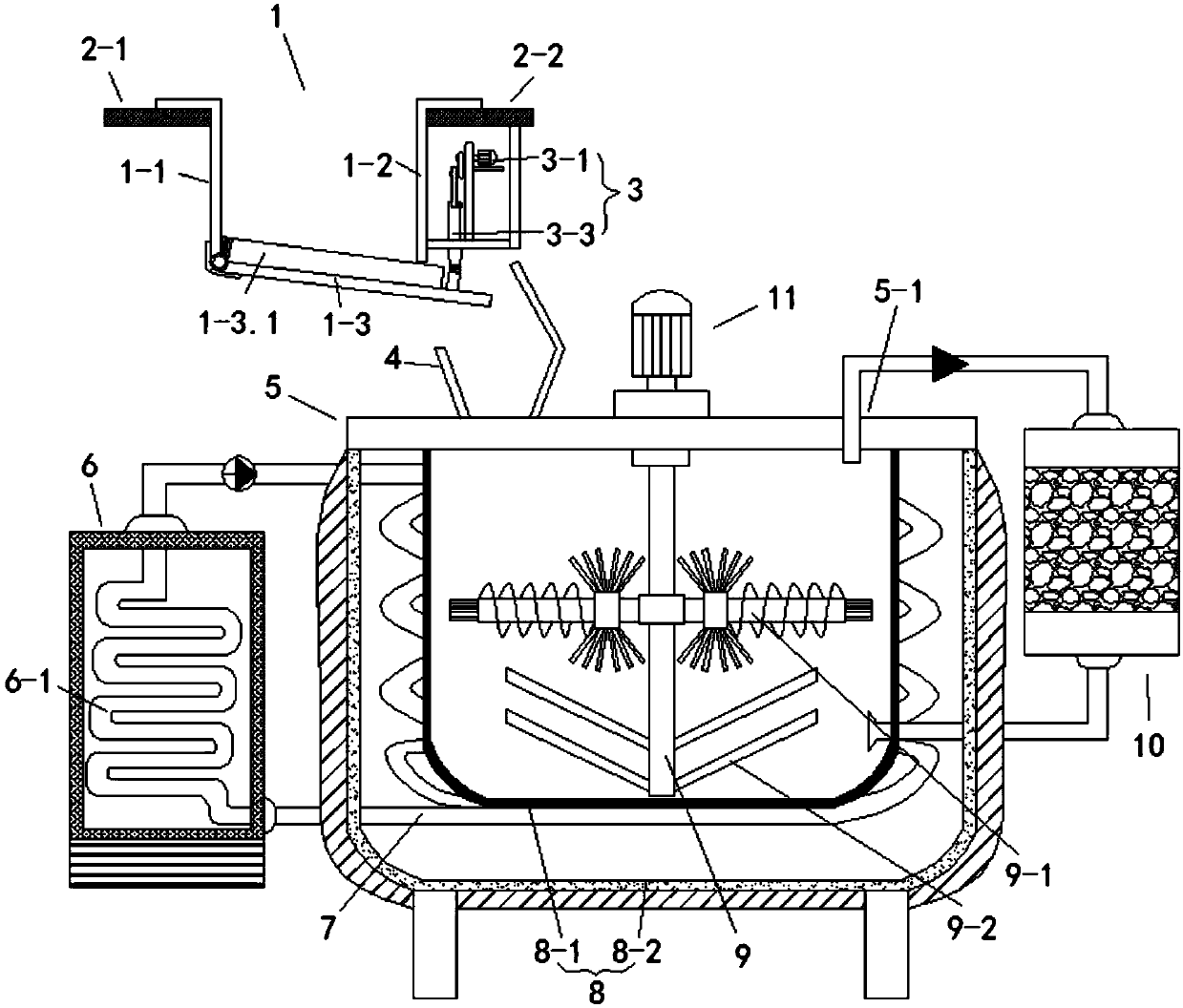

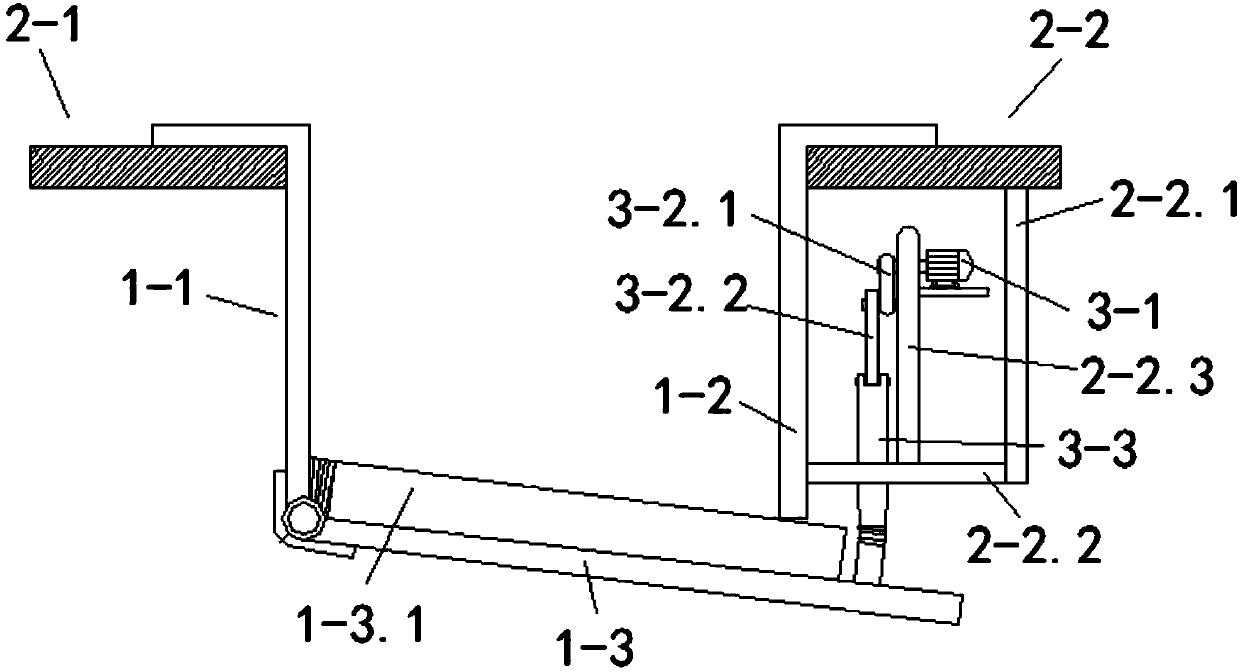

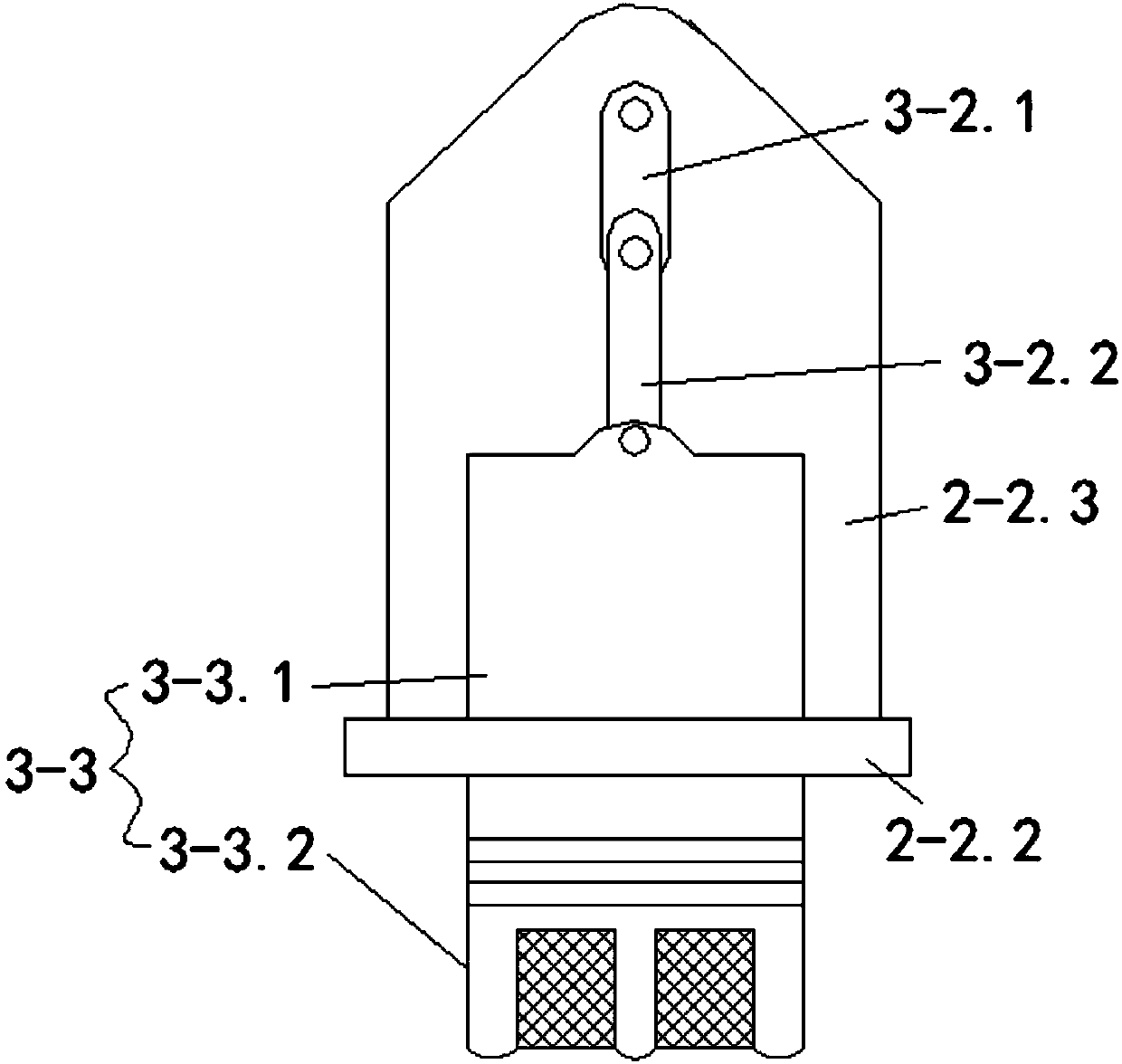

[0028] Such as Figure 1 to Figure 3 As shown, this embodiment provides a medicinal material drying device, which includes a drying tank body 8 and a tank cover 5 matched with the drying tank body 8, and the drying tank body 8 includes an inner tank 8-1 and an outer shell 8- 2. The inner tank 8-1 and the outer shell 8-2 form a heating cavity, and a circulating hot water pipe 7 is arranged around the inner tank 8-1 in the heating cavity. The water tank 6 is connected, and the tank cover 5 is respectively provided with a feed hopper 4 and an exhaust port 5-1 communicating with the inner tank 8-1, and an intermittent feed box 1 is arranged above the feed hopper 4, and the inner tank 8-1 1 is provided with a stirring shaft 9, and the stirring shaft 9 is connected with a motor 11 that drives the stirring shaft 9 to rotate in the inner tank 8-1.

[0029] The intermittent feeding box 1 includes a left box wall 1-1, a rear box wall, a right box wall 1-2 and a front box wall connected...

Embodiment 2

[0035] Such as figure 1 and Figure 4 As shown, the present embodiment is further optimized on the basis of embodiment 1, specifically:

[0036] The exhaust port 5-1 is connected to a dehumidification box 10 filled with water-absorbing sponge through an exhaust pipe, and the dehumidification box 10 is connected to the interior of the inner tank 8-1 through an air intake pipe. In the inner tank 8-1, the water of the medicinal material evaporates After coming out, the water-containing hot air is discharged into the dehumidification box 10 through the exhaust pipe. After the water-absorbing sponge in the dehumidification box 10 absorbs the water vapor in the hot air, the dry hot air is discharged to the inner tank 8-1 through the air intake pipe, and the heat is carried out. Make full use of it, save resources and improve drying efficiency.

[0037] The hot water tank 6 is provided with a serpentine heating pipe 6-1, and the water inlet and outlet of the circulating hot water p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com